Waste Water Treatment and Re-Use

Introduction

Our earth consists of abundant water out of which 97.5% is salt water which cannot be used for domestic purpose. Out of remaining 2.5%, 70% of the water is in the form of Icebergs and glaciers and left with only 1% which is actually usable in its present status. All the more it is imperative to conserve this usable water which is very precious to very existence of life on this earth.

Safe water supply and hygienic sanitation facilities are two basic essential amenities the community needs on a top priority for healthy living. While provision of safe drinking water takes precedence in the order of provision of basic amenities, the provision of hygienic sanitation facilities is equally important.

Since 80% of the water used by the community comes out of the houses in the form of waste water, the waste water treatment and re-use is all the more important to reduce the ever increasing demand for fresh water. The complex question often faced by design engineers is what level of treatment must be achieved in a given application, beyond those prescribed by the Authorities to ensure protection of Public Health and Environment

The object of sewage treatment is to stabilize decomposable organic matter present in sewage so as to produce an effluent and sludge which can be re-used and dispose-off in the environment without causing health hazard or nuisance. In India the quantity of sewage generated is approximately 32 billion cumt per day and out of which we are treating only 29% of the sewage generated.

| Parameter |

Treatment offered |

| Extreme pH (Acidic/Alkaline) |

pH correction to neutral/optimal range |

| TSS load Turbidity Colour |

Primary treatment for coagulation & flocculation |

| High organic load |

Primary chemical treatment followed by Secondary biological treatment |

| Surfactants |

Anti-foaming dosage followed by primary treatment |

Quantity of waste water generated will be around 80 to 85% of potable water used in the premises which can be treated & reused. The organic load in sewage is in the form of fats, carbohydrates and protein constitutes 70% and the rest is inorganic load in the form of salts & metals. The disintegration of organic matter can occur in anaerobic condition but the process is slower than the disintegration in aerobic conditions in the presence of oxygen.

Waste Water Stream and Its Treatment Methodology

Water recycling is reusing treated wastewater for beneficial purposes such as agricultural (generally raw sewage is used for farming), landscape irrigation, industrial processes, toilet flushing, and replenishing a ground water basin (referred to as ground water recharge, recently some State Pollution control boards are not allowing this because of non compliance of standards in treated wastewater).

Typical Characteristics of Waste Water

|

- Extreme pH ( Acidic / Alkaline )

- High Suspended Solids

- High organic load ( BOD / COD )

- Higher content of Surface Active agents

- High turbidity / colour due to colloids

- Presence of one or more heavy metals

|

Effect on Waste Water

Effect of the Characteristics on Quality of Waste Water can be listed as under;

Due to extreme pH, biological process will get affected in the downstream treatment section

Higher organic pollutants calls for higher oxygen demand for degradation Surface active agents tend to form foamy layer in the treatment section

Treatment Scheme for Industry Waste Water

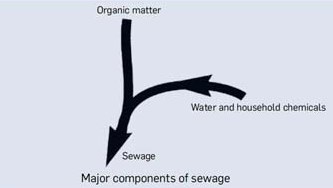

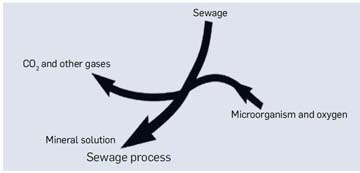

The Figure 1, 2, 3 and 4 indicates sewage cycle with various major components, Sewage process, evolution of an organism with its metabolism.

Treatment Process

|

- Primary : Removal of a portion of the suspended solids & inorganic matter from the waste water.

- Advanced primary : Enhanced removal of suspended solids & organic matter from the wastewater. Typically accomplished by coagulant addition and settling.

- Secondary : Removal of biodegradable organic matter dissolved (in solution or suspension) & suspended solids. Disinfection is also typically included in the definition of conventional secondary treatment.

- Secondary with nutrient removal : Removal of biodegradable organics, suspended solids & nutrients (nitrogen, phosphorus or both nitrogen & phosphorus)

- Tertiary : Removal of residual suspended solids (after secondary treatment), usually by granular medium filtration or micro-filters. Disinfection is also typically a part of tertiary treatment. Nutrient removal is often included in this definition.

- Advanced : Removal of dissolved & suspended materials remaining after normal biological treatment when required for various water reuse applications.

|

Domestic Sewage Treatment

The microbial population in treatment process can be cultured from the following system

- Suspended growth system-In suspended growth system microorganisms remain in suspension and their concentration is related to MLSS (mixed liquor suspended solids)

- Attached growth system- In attached growth system microorganisms is developed over mobile or immobile solid covered in biomass (slime)

- Combined growth system In combined growth system, both systems are used to attain the shock loads.

- Suspended growth system is generally proposed due to its merits and excellent performance.

Technologies

- Extended aeration with Activated sludge process

- Sequential Batch reactor

- Membrane Bio Reactor

- Rotating Bio Bed Reactor

- Fluidized Bio Bed Reactor

- Submerged Aerobic Film Reactor

- Trickling Filters

- Oxidation Ponds / Lagoons

- Septic Tanks and Soak Pits/ Trenches

Extended Aeration Process

Activated sludge process is the biological process by which non-settleable substances occurring in dissolved and colloidal forms are converted into settleable sludge which is removed from the liquid carrier (water)

Treatment is well suitable for completely populated community and doesn't require skilled labour for handling the plant. Process is time tested and requires more number of units to achieve BOD less than 10 PPM, like coagulants required for better quality.

It is difficult to operate the plant at low flows. Coagulants handling will be crucial and more number of units calls for more power consumption.

Sequential Batch Process(SBR Technology)

- Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank.

- There is a degree of flexibility associated with working in a time rather than in a space sequence.

- Plant requires less space due to batch process, well suitable for modular growth.

- Can be handled for smallest flows.

- Quality can be achieved without coagulants.

- Require skilled labour as process will be timer based automation and good quality of decanters required.

Membrane Bio Reactor(MBR Technology)

- It is continuous process of activated sludge treatment, but solids separation will be done through pressurised system or through media. As there is physical barrier for solid separation, quality of treatment will be good.

- Well suitable for any type of growth pattern can handle smaller flows, quality of treatment is good. Requires less space.

- But initial cost and running cost is very high, require skilled labours to handle. Cleaning of membrane will be tedious

Rotating Bio Bed Reactor (RBC - Rotating Biological Contactor)

- It is combined growth process. Bacteria's are allowed to grow on media, which will be exposed to atmospheric air and also kept in water for food.

- Well suitable for smaller capacity and doesn't require skilled labour to handle, quality of water is good.

- Quality will not be consistent and breakdown of plant chance will be more as the rotating drum is aligned on central shaft.

Fluidized Bio Bed Reactor(MBBR - Moving Bed Bio Reactor)

- In fluidized bed reactors, cells are "immobilized" in small particles which move with the fluid. The small particles create a large surface area for cells to stick to and enable a high rate of transfer of oxygen and nutrients to the cells.

- Well suitable for all type of community, doesn't require skilled labour, space required will be less. Can be installed for all capacities. Quality of water is good.

- Quality is not consistent, loss of media to be corrected often, sludge quantity fluctuates due to biomass on media.

Submerged Aerobic Film Reactor (SAFR)

It is combined growth process. Where bio media is fixed and bacteria's are allowed to grow on media, which will be having air supply from below.

- SAFR is generally used to augment the capacity of existing plant.

- Quality of water is similar to attached growth technology.

- Doesn't require skilled labour. No loss of media.

- Quality is not consistent due to bio mass development on media, Supporting structure for media should be anti corrosive else media fixing will not be possible.

Trickling Filters

- Attached growth process and media used to grow bacteria's by trickling sewage over media.

- Very old concept and practically redundant.

Oxidation Ponds

- Oxidation ponds, also called lagoons or stabilization ponds are large, shallow ponds designed to treat wastewater through the interaction of sunlight, bacteria, and algae.

- It requires lot of land space.

Reuse of Treated Waste Water

Water reuse has a rightful place & has an important role in planning & efficient use of water resources. It is the intentions of the statutory body that all possible steps need to be taken to encourage development of water recycling facilities so that recycled water may be made available to help meet the growing water requirements. Further it has been technically proven that the waste water treatment processes currently in use can be used to produce water of good quality for reuse.

While using the treated waste water for reuse, it is imperative to address public concerns with regard to health & environmental issues in more rigorous & transparent manner.

Waste Water Reuse, Its Application & Constraints

|

|

| Water reuse has a rightful place & has an important role in planning & efficient use of water resources. |

- Application: Agricultural irrigation, crop irrigation, commercial nurseries

Constraints:

- Surface & ground water contamination if not managed properly. Marketability of crops & public acceptance

- Application: Landscape irrigation, parks, school yards, freeway medians, golf courses, cemeteries, green belts, residential.

Constraints:

- Effect of water quality, particularly salts on, soils & crops.

- Public health concerns related to pathogens (e.g., bacteria, viruses & parasites)

- Use area control including buffer zone may result in high user costs.

- Application: Industrial recycling & reuse, cooling water, boiler feed, process water, heavy construction.

Constraints:

- Constituents in reclaimed water related to scaling, corrosion, biological growth & fouling.

- Public health concerns, particularly aerosol transmission of pathogens in cooling water.

- Cross connection of potable & reclaimed water lines.

- Application: Ground water recharge, ground water replenishment, salt intrusion control, subsidence control.

Constraints:

- Possible contamination of ground water aquifer used as a source of potable water. Organic chemicals in reclaimed water & their toxicological effects.

- Total dissolved solids, nitrates & pathogens in reclaimed water.

- Application: Recreational/ environmental uses, lakes & ponds, marsh enhancement, stream flow augmentation, fisheries, snowmaking.

Constraints:

- Health concerns related to presence of bacteria & viruses (e.g. Enteric infections, eye, ear, nose infections) Eutrophication due to nitrogen & phosphorus in receiving water. Toxicity to aquatic life.

- Application: Non potable urban uses, fire protection, Air conditioning, Toilet flushing.

Constraints:

- Public health concerns about pathogens transmitted by aerosols. Effects of water quality on scaling, corrosion, biological growth & fouling. Cross connection of potable & reclaimed water lines.

- Application: Potable reuse, blending in water supply reservoirs, pipe-to-pipe water supply.

Constraints:

- Constituents in reclaimed water, especially trace organic chemicals & their toxicological effects. Aesthetics & public acceptance. Health concerns about pathogen transmission, particularly enteric viruses.

|

Method of Storage

Storage of waste water has become an important issue in a number of reuse applications & especially where communities are moving towards zero discharge of effluents. Storage reservoirs can be generally closed or open type.

Some of the principle problems with open type reservoirs are;

- Release of odors principally Hydrogen sulphide.

- Temperature stratification

- Loss of residual chlorine.

- Low dissolved oxygen resulting in odors and fish scales.

- Excessive growth of algae.

- High level of turbidity & colour.

- Re-growth of micro-organisms.

- Water quality deterioration due to bird & rodent population.

- Some of the principle problems with closed type reservoirs are;

- Stagnation of water

- Release of Odor

- Loss of residual chlorine ( much lower when compared to open type)

- Re-growth of micro-organisms.

Figure referred above indicates pictorial concept of generation of waste water and its process for achieving water for reuse / recycling for intended purpose.

Conclusion

Inadequate water supply & water quality represent serious contemporary concerns for many municipalities, industries, agriculture & the environment in various parts of the world. Several factors have contributed to these problems such as continued population growth in urban areas, contamination of surface water & ground water, uneven distribution of water resources & frequent droughts caused by the extreme global weather patterns. For more than a quarter century, a recurring thesis in environmental & water resources engineering has been that improved waste water treatment provides a treated effluent of such quality that it should not be wasted but put to beneficial use. This conviction in responsible engineering, coupled with the vexing problem of increasing water shortage & environmental pollution, provides a realistic framework for considering reclaimed water as a water resource in any parts of the world. Water reuse has been dubbed as the greatest challenge of the 21st century as water supplies remain practically constant & the demand increases due to increase in population & per capita demand. Water reuse accomplishes two fundamental functions namely,

- The treated effluent is used as a water resource for beneficial purpose

- The effluent is kept out of streams, lakes & beaches thus reducing the pollution of surface water & ground water.

Thus recycling of waste water is beneficial to mankind & also helps to keep the ecological balance between nature & mankind.

Author

BSA Narayan

D, MAPLE Engg-Design Services (India) Pvt. Ltd

|

BSA, as fondly called among the fraternity members, is a graduate in Science from Bangalore University, 1971 and obtained degree in Civil Engineering in 1975 with Public Health Engineering as specialization from Mysore University.

BSA was engaged as a Senior Design Engineer in Semac Pvt. Ltd., and S.G. Deololikar, leading Consulting Engineering firm in India for over Six years before joining International Consulting Organization in 1981. BSA joined Potential Service Consultants (P) Ltd in 1989, as Principal Consultant / Partner to provide quality and timely services. Potential has carried out a number of mega projects for various institutions and Clients in India also abroad.

Currently he is the Managing Director of Maple Engg-Design Services (India) Pvt. Ltd. He has designed Plumbing, Fire Protection and Industrial Piping System including Water and Sewage Treatment Plants, Central LPG system for Hotels, Hospitals, factory complexes, software building, software parks and commercial buildings in co-ordination with reputed Indian and Multinational Architects and Developers.

Being one of the Founder Members and current Vice President of the Indian Plumbing Association (IPA) which was established in 1993, BSA Narayan is also a Fellow Member of Chartered Institute of Plumbing and Heating Engineers U.K, Life Member of Association of Consulting Civil Engineers, Member of Institute of Engineers, Affiliate Member of World Plumbing Council and Chairman, Convener of NBC - Part 9. In 2007 he was awarded the prestigious life time achievement award by Indian Plumbing Association (IPA).