Modern Construction Requires Modular Formwork

Modern modular formwork system is a trend that is catching up in the formwork industry. In an interaction with Built Constructions magazine, Mr. Shreeniwas Kelkar, Product Manager, Doka India Pvt. Ltd., says that enough opportunities can be explored in high-rise construction, power , infrastructure projects.

Huge increase in High Rise structures and also there is good growth in infrastructure projects such as airports, highways, power, etc, it is imperative for the project owners and investors to complete the projects ahead or on time to generate revenues. The modernization & mechanization taking place in these projects has a vital role to play to achieve speed, increase productivity and utilise economy of scale in bringing down the unit cost to meet the rising demand. One of the key challenges, formwork segment faces is the completion of fast track projects. By going in for a System / Engineered Formwork, substantial savings are possible by faster return on investments.

|

Emerging trends witness in industry is modern modular formwork systems are being designed with features that facilitate, accelerated and economical construction workflows in monolithic construction projects. For instance, the Doka OneGo aluminum formwork system is compact and lightweight enough to need only a few form-tie points and floor props. |

It has synchronised forming and stripping processes, integrated stripping aids such as a stripping head for floor-slab formwork and chamfered panel joints. The formwork can be reused immediately. It adapts to the most varied ground plan shapes.

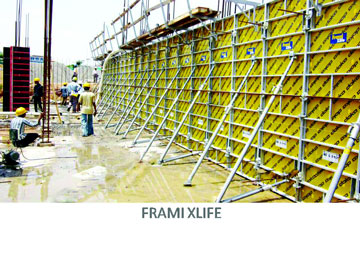

Aluminium formwork is better suited to structures with a repetitive design, typically residential structures where it can be reused many times over through the construction cycle. As the lending rates, finances and several other factors are becoming a problem for the construction industry, the proportion of the usage of system formwork compared to traditional formwork is increasing to save the construction time. Few years back, Doka launched “Frami Xlife”, a panel formwork system, easy to handle and with high number of repetitions. We received a tremendous response to this system due to several factors, like firstly, the skilled man power is scarcely available at the sites, as most of the formwork gangs are from regions like Orissa, West Bengal etc, where they are now able to find job opportunities in their own regions with sufficient pay wages, secondly the cycle time is also very less for panel formwork compared to traditional one and thirdly, if these formworks are used for several times, they turns out to be a economical, better and safer option. We believe, there is much more to be captured in the panel formwork segment and will be launching some new light weight products in the same segment soon for horizontal slab structures.

|

Driving Factors for Growth

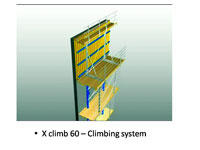

Going ahead, Doka will be focus on rendering “Total Formwork Solutions” to customers in the areas of high-rise construction , power , infrastructure projects apart from general civil engineering . Well-structured procedures and speedy progress take top priority on every high-rise project. Building on the experience amassed from 500-plus successful automatic climbing projects all over the world, Doka formwork specialists has developed made-to-measure complete solutions for each high-rise build and every set of requirements. Along with the preparation of detailed deployment plans for the high-performance SKE 50 and Xclimb 60 automatic climbers, the Doka range of services also includes drawing up overall concepts that take all the relevant influencing factors duly into account to ensure optimization of cycle times and the entire construction process. Xclimb 60 is the automatic climbing protection shield that maximizes safety for forming and concreting work on floor slabs and walls. The shield fully encloses and secures the four topmost levels as the building rises.

|

An accepted standard for cost efficiency in high-rise construction, the powerful Doka SKE 50 and SKE 100 automatic climbers also perform to maximum effect in the construction of bridge towers, significantly accelerating CIP concreting work while at the same time ensuring totally safe conditions for working at lofty heights.

|

Doka’s modular and rentable composite forming carriages and the newly developed free cantilever traveller designed for maximum cost efficiency are high-performance all-inclusive solutions for optimised progress on all bridge superstructure builds. |

The fully mechanised SK175 cooling-tower formwork can achieve and maintain a one-day cycle per concreting section on specialised cooling-tower builds. Precision adjustment of the cooling-tower formwork and the extremely robust steel formwork sheeting combine to ensure dimensional accuracy without sacrificing speed as the structure rises and for the construction of liquefied natural gas tanks. Doka‘s crane-lift MF240 and 150F climbing formwork systems offer two efficient solutions for short cycle times combined with a very high standard of safety.

Doka also offers the comprehensive range of services that combine with its products to make high-end complete solutions for every formwork project.

- Doka Wall / Column System

- Panelled system like Frami Xlife etc.,

- Large Area Top-50

- Doka Floor System

- Doka Flex 1-2-4

- DokaFlex Table

- Doka Load bearing towers such as d3

- Doka Climbing System

- Platform SCP,

- Automatic Climbing formwork SKE

- Dam Formwork

- Cooling tower formwork

- Climbing formwork Xclimb 60 , MF 240, 150F

- Working and Protection platforms

- Floor protection system

- Doka Lubeca Core wall Jump System

- Rental

- Achieves desired cycle time

Initial investment is less in conventional formwork, considering the less repetition, replacing the materials for many times with newer ones, repetitive making cost and writing off the cost in the project itself without taking into another project makes the conventional formwork ultimately costlier. Also the selection of materials for conventional formwork depends on the experience and skill of the person deciding and also identification of conventional formwork in large scale projects is a tedious and an uphill task for continuous usage.

Planning and Operation

The concrete forming plan and selection of form handling equipment can have serious consequences for other trades and operations, including both subcontractors and the general contractor. Form work planning typically concentrates on speed of erection and removal which reduces cost through form reuse and minimization of manpower requirements. Fast form work erection and recycling tends to accelerate completion of the structure, thus allowing more time for follow-up operations such as mechanical and electrical installations and architectural finishes. Therefore all features of a proposed form work system and their effect on other aspects of the work must be carefully analyzed, and cost comparisons must be made of the various options. In the discussion that follows a typical high-rise building serves as an example.

|

Adoption of monolithic construction aluminum formwork system has picked up tremendously in the past four to five years, due to its lightweight (vis – a- vis steel formwork system) and can be tailor –made to allow single monolithic casting, walls, columns, beams and slab in one pour, thereby reducing construction time and costs thus making it affordable for common players.