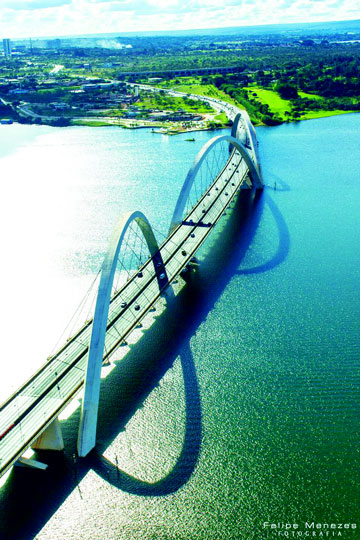

Juscelino Kubitschek Bridge, Brazil

An Inspiring Architecture-Astounding Beauty

|

|

The JK Bridge represents artistry as well as engineering prowess, soaring and swooping gracefully across the waters by day and joined at night by a host of twinkling

lights that make it into a veritable visual feast. |

The Juscelino Kubitschek Bridge is also known as the President JK Bridge or simply the JK Bridge, crosses Lake Paranoá in Brasilia in the capital city of Brazil. The bridge's astounding beauty and design sophistication reflect the intent of the former president of the country, Juscelino Kubitschek de Oliveira, for whom it is named, when he made the commitment to build Brasilia as a majestic new capital.

The JK Bridge represents artistry as well as engineering prowess, soaring and swooping gracefully across the waters by day and joined at night by a host of twinkling lights that make it into a veritable visual feast. Alexandre Chan designed this gorgeous span with instructions to create something special, and he certainly met that requirement. It was conceived and built as part of the Orla Project which is a comprehensive sustainable development initiative of the Brazilian government, focused on planning and preservation for all river and ocean coastal activities in the country.

The requirement for a bridge in this location arose from increasing levels of congestion on the two existing bridges across the lake, located to the south of the proposed third crossing. The congestion on these bridges became a significant problem as the city expanded at a faster rate than anyone predicted during their design.

Despite some modifications to these bridges they were unable to cope with the high level of traffic present. By constructing a bridge in the chosen location the travel distances between outlying areas of the region were reduced. This had the effect of increasing the accessibility of the city and its amenities to people living in these communities. A secondary aim of locating a bridge at this point on the lake was to revert on the privatisation of the edges of the lake which had occurred in the area immediately surrounding the site. The introduction of a crossing means that the area becomes part of the public realm rather than the private one. The design of the bridge was conceived by architect Alexandre Chan, with close collaboration from structural engineer Mario Vila Verde, and associated design teams.

Ravishing Design

The form of the bridge evidently reflects its simple structure; the slender steel arches remain clearly visible from different aspects, an attribute that clearly emphasises their functional role. A feeling of stability is generated from this ability to always be able to identify the structure of the bridge. The layout of the structure is such that a distinct feeling of instability is created by the combination of the way that the arches criss-cross the road deck and the angles at which the stays are attached vary depending upon the location. The proportions of the JK Bridge are well considered, with the cables obviously being the most slender element.

|

Care has been taken in the design to integrate the concrete supports with the steel elements and there is no visible distinction between them. By positioning the arches above the deck sensible heights have been maintained for navigation, whilst the form of the arch is still fully exploited. Another benefit of having repeated the arch element three times across the central span is that the approach spans are proportionally smaller than the main spans. While this effect is not as pronounced as it would be in a bridge across a valley it still contributes to the aesthetic appeal of the bridge. Manipulation of elements can also be identified in the arches, the top of the arches are tapered to be smaller than the base. This has an aesthetic effect but is also structurally important for maintaining the thrust line within the arch at the base.

Urban Landmark

The choice of a steel arch bridge to span the lake environment is somewhat unusual. The type of bridge associated with such an environment is more commonly a beam and slab bridge or for longer spans a suspension bridge, simply because these techniques are easier to design and construct. The JK Bridge however is an urban landmark it reflects the dynamism of the growing city, but maintains links with the natural environment in which it is placed. The architect has used the form of this structure to imitate the idea of a stone skimming across the water's surface.

The JK Bridge is an important artery for the city and its continuing development. The width of the bridge has been determined by the perceived level of traffic and its predicted growth, as the choice of design eliminates the possibility of further expansion. The bridge has been designed to have six vehicle lanes and two pedestrian lanes having dimensions that correspond to local normal technical specifications.

|

Rather than having been designed to blend in with the surrounding environment in an unobtrusive way the JK Bridge has been designed as a monumental landmark that mimics the modern fabric of the city, this is a factor that has clearly influenced the choice of bridge type. For this bridge it is clear that the architect chose to use a steel arch bridge for aesthetic rather than structural reasons. The absence of tension in an arch bridge allows for the use of materials that have a low tensile strength. An arch allows for the creation of a longer span than that which can be achieved using a beam bridge in those materials.

|

|

| The absence of tension in an arch bridge allows for the use of materials that have a low tensile strength. |

In making the decision to construct the JK Bridge predominately from steel the design team have intentionally used engineering skill to a high degree. They have begun to develop a base of skills and knowledge amongst engineers that may lead to an expanded use of steel in construction within the country. The main issue for the construction was the lack of skilled construction workers due to the fact that steel was not a well used material. The principal behind the construction technique was that the workers involved would develop the necessary skills so that they are able to competently use steel in future projects.

The lack of local skilled steelworkers meant that despite the low labour costs in the country the construction cost of the JK Bridge was higher than an equivalent concrete bridge. This is because external skilled worker were needed to aid with the construction process. Aside from being a new technology, the reduced weight of steel as a construction material made the transportation of the prefabricated arch segments easier, and cheaper than if concrete segments had been used. For several reasons concrete has been chosen for the construction of the Bridge piers. This combined method of material choice has meant that whilst a new technology has been used, it has not had a detrimental effect on the speed of the construction process; something that is often seen in construction projects in Brazil.

Prudence over Future Changes

The choice of a steel arch bridge of this type makes further additions to the bridge almost impossible. Given the reasons stated for the construction of a bridge at this location, the designers should have considered this aspect in more detail. Whilst predicted future growth rates have been used to over design the bridge for current traffic levels, it would be disastrous for the local economy if a similar problem were to occur again in the future.

Construction of JK Bridge

The foundations of the JK Bridge used piles combined with concrete pile caps. Due to poor ground conditions on the bed of the lake they reached a depth of 65 metres; this was so that both horizontal and vertical homogeneity of soil layers was achieved.

|

The JK Bridge contained three types of pier, those on the approach spans, the central piers, and the temporary supports. The piers in the approach spans were constructed from concrete. They have a hollow form, with longitudinal wall thicknesses of 25cm, and external dimensions of 11m by 2.5m. The shorted ends of the piers have a significantly larger wall thickness; it is these sections that support most of the weight of the deck at these locations. The four central piers each contain two concrete elements with a thickness of 2m which are connected to the same foundation block. One element is inclined at the same angle as the start of the arch, while the other is vertical. This arrangement allows both horizontal and vertical forces to be resolved satisfactorily.

The deck of the JK Bridge has been constructed using the incremental launching technique. Incremental launching means that the deck is created in factory like conditions on site avoiding costly transportation of large elements. By selecting to undertake construction at an abutment, the problems associated with the construction over water present in this case are eliminated. This method of construction is likely to have been chosen because it is identical to the method used for concrete bridges a technology with which the constructors will have been very familiar.

|

|

| The principal alternative method for arch bridge construction is suspended cantilever construction. |

The pavement surface applied to the bridge deck is Dermasfalt [5]. This is a unique polymeric thin layer paving product that was first used in Brazil in 1984. It is likely that the design team chose this product because it has many advantages over conventional pavement materials, and has been widely used in Brazil particularly for steel deck bridges. It significantly reduces the dead weight of the structure as it is applied as a thin layer (averaging 8mm). It can be applied directly to the structure without the need for additional binding materials.

The method selected for the construction of the steel arches was to support them on formwork until they were complete. This formwork was made from steel trusses and was supported on the deck; during this process the load was supported by both the permanent and temporary supports and foundations. The sections of the arches that protrude directly from the water's surface are constructed from high performance concrete. There are potentially several reasons behind this choice; the first is that since concrete is the most widely used construction material in Brazil it will also be the most trusted material, and therefore deemed suitable for such an application.

The prefabricated arch segments were moved into the appropriate position on the surface of the lake by floating platforms. The arch was then constructed by being lifted into place in pieces by cranes, and was supported by the formwork until the keying piece was inserted. The keying part of each arch was inserted at night; this was to allow for controlled temperature conditions, whilst the final closing weld was completed.

Complementary Techniques Adopted

The principal alternative method for arch bridge construction is suspended cantilever construction. This involves the use of temporary cable stays to support the structure during construction. It does however involve the construction of large temporary towers which are needed for the suspension of the cables. The foundation conditions at the edges of the lake are preferable to those found on the bed of the lake, so for a single arch structure this would be a viable construction method. However for the bridge design chosen it would be unsuitable as there are three arches rather than just a single arch.

|

Bridge design is done using a limit state philosophy. The JK Bridge is primarily a steel bridge, with some concrete elements, with both of these materials design is at ultimate limit state (ULS) and then further checks are carried out at serviceability limit state (SLS). Since the JK Bridge is located in Brazil it is likely to have been designed using American bridge loadings, as these are more sensible than the loadings that are used in the UK.

Inspection and Monitoring

During its construction the JK Bridge was fitted with over 50 sensors in the cables and arches in order to monitor the deflections and stresses both during construction and once the bridge is in service. In fitting these sensors to the bridge the designers have eliminated some of the need for close inspection. However other components of the bridge will still need to be inspected regularly. While the cross section of the deck will allow for this, inspection of the arches themselves will be much more difficult.

References:

http://www.bath.ac.uk/ace/uploads/StudentProjects/Bridgeconference2007/conference/mainpage/Bailey_Kubitschek.pdf

http://www.globalsalesgrowth.com/brazils-juscelino-kubitschek-bridge