PRE ENGINEERED METAL BUILDINGS (PEMBs)

An Overview and Comparison

HISTORY

The very notion of Pre-Engineered Buildings in India dates back to many centuries during which the country witnessed a rich architectural evolution spanning across many civilizations that prospered here at various periods in time. If clay bricks were used as building materials during Indus Valley Civilization, stones were used to make buildings and temples during the rules of many dynasties during the medieval times. Every Indian Temple is a remarkable example of Pre-Engineered Construction. It was only during the modern times that concrete has emerged as one of the most suitable construction materials and is used for almost all type of buildings and structures.

The concept of Pre-Engineered Metal Buildings originated from the USA, in the early years of 20th century. Applications ranging from structures like parking shed to very large span structures like Aircraft Hangar. Pre-engineered metal buildings can be commonly identified in the Industrial, Infrastructural, Warehousing and Commercial sectors. Short delivery time combined with Cost effectiveness and aesthetics make PEB an attractive proposition for the prospective Customers. Pre Engineered Metal Buildings typically refer to Steel Buildings which rely on Standard Engineering Designs for a variety of Off-the-shelf configurations, wherein each component of the building comes pre-punched, marked, completely constructed to specifications 'off-site' and shifted to site for assembly and erection. It requires minimum 'on-site' work and the erector has to simply assemble the pieces together at site by bolting. However, in today's context, where the industry has started to offer custom-designed metal buildings to suit the particular requirements of each client, the term PEB has become somewhat a misnomer. Though Metal Building Systems is more apt, the structures continue to be referred to by its common and popular term, 'Pre-Engineered Buildings'.

However, by the advent of steel, construction industry enormously got benefitted by its versatility and robustness. It is steel that is now fast emerging as the preferred material of the present and future for construction of buildings and structures. And this is where Pre Engineered Buildings or Metal Building Systems mark a new beginning. Use of Structural Steel Sections ushered a new era, a new beginning from steel in buildings to buildings in steel.

|

PEMB versatility

Time is the essence of any project and this is where PEMBs score over any other conventional building system. PEMBs have many advantages over conventional erection practices and are very well suited for a wide range of applications. These

|

are faster to construct, are cost economical over life cycle as they are maintenance free, offer architectural flexibility, look pleasing. Pre Engineered Buildings are known for faster engineering and manufacturing of buildings, delivery and erection at sites. Though the time varies from project to project, typical time taken for completion of a regular size and complexity of project is 12-16 weeks. Due to low maintenance requirements, Life Cycle Cost of such buildings is typically lower than that of any other conventional Structure.

Pre-Engineered metal buildings use a predetermined inventory of raw materials that satisfy a wide range of structural and aesthetic requirements. The individual components required to make the PEMBs are pre-engineered with respect to their shapes, connection details and support arrangements. These results in faster design and detailing of the structure combined with speedy fabrication.

Introduction

| 'Pre-engineered Metal Building System-PEMBS' is widely accepted across the globe as an efficient alternative to conventional buildings. It is the most affordable and flexible building system ideal for Industrial, Institutional or commercial application. The system offers excellent features such as speed, quality, strength and value making it the most preferred building system in the world. |

|

All pre-engineered structures are designed structures, fabricated to conform to the specifications of the end user. The advantage of pre-engineered structures is that they are factory-built and designed to be erected in the shortest possible time. Each pre-engineered structure is shipped as a complete building kit including all the necessary materials and instructions to erect it.

Technological advancements in design and construction mechanisation over the past few years have immensely contributed in achieving faster and safer completion of projects. Advent of Pre-engineered Buildings as a system is one such revolution. Though its origin can be traced back to 1960's its potential has been felt only during the recent years.

Pre-Engineered system of buildings use a combination of built-up sections providing basic steel frame work which subsequently are complimented with various options for covering roofs and walls. Roofs can be single skin sheeting with or without insulation and walls can be cladded or bricked. The concept is designed to provide a complete building envelope system which is air tight, energy efficient, optimum in weight and cost, and custom designed keeping the utilisation, a priority.

Being a versatile building system, it can be fitted with different structural accessories including mezzanine floors, canopies, fascias, interior partitions etc and can be finished internally to serve any required function together with distinctive aesthetics architecturally. It is most suitable for any low-rise building and offers numerous benefits over conventional buildings.

Pre-engineered buildings are generally more advantageous in case of low rise buildings in terms of constructability, economy and ease of construction. However the maximum eave heights can go up to 25 to 30 metres. PEB system can be easily adopted in case of Warehouses, Factories, Workshops, Offices, Gas Stations, Vehicle Parking Sheds, Showrooms, Aircraft Hangars, Metro Stations, Schools, Recreational, Indoor Stadium Roofs, Outdoor Stadium Canopies, and Platform Shelters and many more such structures.

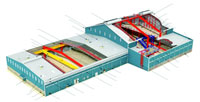

A Typical PEMB

A typical PEMB makes use of three distinct product categories namely;

- Primary Structural Framing (comprising of mainly columns and rafters) consisting of built-up "I" sections, both prismatic as well as tapered.

- Secondary framing consisting of Cold formed "Z" and "C" sections used as roof purlins, wall girts and eave struts.

- Roll formed profiled sheeting used as roof and wall panels.

The arrangement and nature of connections resulting from the assemblage of the above to form a structure is pre-engineered resulting in the development of hundreds of typical details. These details greatly reduce the design and detailing time as most of the details are typical and standard for most buildings.

Built-up tapered sections when used as Primary Structural members in columns and rafters, it is observed that there is a considerable weight saving as compared to conventional hot rolled prismatic sections. Savings can be as high as 30 to 35 % added to the fact that material is used only where required from strength point of view. Use of cold formed sections for roof purlins and sidewall girts in the shape 'Z' greatly helps in reducing the weight to the tune of 30% as compared to the use of hot rolled channels used in conventional steel structures. Scrap costs are greatly reduced from the production processes of the built up and cold formed sections. Cost of foundation is less. This is due to the use of wide clear span structures combined with longer economic bay spacing resulting in less number of footings as compared to conventional structures.

Primary Framing System

In conventional steel buildings, mill-produced hot rolled sections (beams and columns) are used. The size of each member is selected on the basis of the maximum internal stress in the member. The hot rolled section has a constant depth, many parts of the member (represented by the hatched area), in areas of low internal stresses, and are in excess of design requirements.

Frames of pre-engineered buildings are made from an extensive inventory of standard steel plates stocked to the Pre Engineered Building. Pre Engineered Building frames are normally tapered and often have flanges and webs of variable thickness along the individual members. The frame geometry matches the shape of the internal stress (bending moment) diagram thus optimizing material usage and reducing the total weight of the structure.

Secondary Framing System

The Secondary Framing System comprises of components like Z-shaped purlins and cladding wall Girts made of high grade steel sheets and are lighter than the hot rolled 'I' or 'C' sections. These are dealt below in detail separately.

Statistics-Current Scenario

|

At present, the total steel production in the country is about 45 Million Ton as against the total production of about 1280 Million Ton in the world. Per capita steel consumption in India is about 42 kg whereas it is 270 kg in China. About 10% of steel goes to the construction industry and amidst it PEB accounts only for the 0.5 Million Ton. |

In the next 5 years, with the boost given by Government of India, the steel production will be doubled and it is anticipated that the steel intensive construction will rise up to 20 Million Ton. Owing to several advantages of PEB, the potential will rise up to 2.0 Million Ton which is nearly four to five times of today's scenario.

Pre Engineered vs. Conventional

UltraTech Cement Ltd, Hirmi,Chhattisgarh, India, 65 M SPAN; Courtesy-Pebs Pennar

Pre engineered buildings are generally low rise buildings however the maximum eave height can go up to 25 to 30 meters. Low rise buildings are ideal for offices, houses, showrooms, shop fronts etc. The application of pre engineered buildings concept to low raise buildings is very economical and speedy. Buildings can be constructed in less than half the normal time especially when complemented with the other engineered sub systems.

The most common and economical type of low rise buildings is a building with ground floor and two intermediate floor plus roof. The roof of low rise buildings may be flat or sloped. Intermediate floors of low rise buildings are made of mezzanine systems. Single storied houses for living take minimum time for construction and can be built in any type of geographical location like extreme cold hilly areas, high rain prone areas, plain land obviously and extreme hot climatic zones as well.

Table 1 shows comparison between Pre Engineered Metal Buildings and Conventional Steel Buildings in low rise building constructions.

TABLE 1 - Pre Engineered Metal Buildings Vs Conventional Steel Buildings

|

SL.NO

|

PROPERTY

|

CONVENTIONAL BUILDINGS

|

PRE ENGINEERED METAL BUILDINGS

|

|

1

|

STRUCTURE WEIGHT

|

Primary steel members are selected hot rolled "T" sections. Which are, in many segments of the members heavier than what is actually required by design? Members have constant cross section regardless of the varying magnitude of the local stresses along the member length.

|

Pre engineered buildings are on the average 30% lighter because of the efficient use of steel. Primary framing members are tapered built up section. With the large depths in areas of higher stress.

|

|

Secondary members are selected from standard hot rolled sections which are much heavier.

|

Secondary members are light weight roll formed "Z" or "C" shaped members.

|

|

2

|

DESIGN

|

Each conventional steel structure is designed from scratch with fewer design aids available to the engineer.

|

Quick and efficient: since PEB's are mainly formed by standard sections and connections design, time is significantly reduced. Basic design based on international design codes are used over and over.

|

|

Substantial engineering and detailing work is required from the very basic is required by the consultant with fewer design aids.

|

Specialized computer analysis design programs optimize material required. Drafting is also computerized using standard detail that minimizes the use of project custom details.

|

|

Extensive amount of consultant time is devoted to the alterations that have to be done.

|

Design shop detail sketches and erection drawings are supplied free of cost by the manufacturer. Approval drawing is usually prepared within in 2 weeks.

|

|

As each project is a new project engineers need more time to develop the designs and details of the unique structure.

|

PEB designer's design and detail PEB buildings almost every day of the year resulting in improving the quality of designs every time they work.

|

|

3

|

DELIVERY

|

Average 20 to 26 weeks

|

Average 6 to 8 weeks

|

|

4

|

FOUNDATIONS

|

Extensive, heavy foundation required.

|

Simple design, easy to construct and light weight.

|

|

5

|

ERECTION SIMPLICITY

|

The connections are normally complicated and differ from project to project resulting tin increasing the time for erection of the buildings.

|

Since the connection of compounds is standard the learning curve of erection for each subsequent project is faster.

|

|

There has to be separate allocation of labour for the purpose of erection.

|

Periodic free of charge erection is provided at the site by the manufacturer.

|

|

6

|

SEISMIC RESISTANCE

|

Rigid heavy frames do not perform well in seismic zones.

|

The low weight flexible frames offer higher resistance to seismic forces.

|

|

7

|

OVER ALL PRICE

|

Higher price per square meter.

|

Price per square meter may be as low as by 30 % as the conventional building.

|

TABLE 1 - Pre Engineered Metal Buildings Vs Conventional Steel Buildings

|

SL.NO

|

PROPERTY

|

CONVENTIONAL BUILDINGS

|

PRE ENGINEERED METAL BUILDINGS

|

|

8

|

ERECTION COST AND TIME

|

Typically, conventional steel buildings are 20% more expensive than PEB in most of the cases, the erection costs and time are not estimated accurately.

|

Both costs and time of erection are accurately known based upon extensive experience with similar buildings.

|

|

Erection process is slow and extensive field labour is required. Heavy equipment is also needed.

|

The erection process is faster and much easier with very less requirement for equipment.

|

|

9

|

ARCHITECTURE

|

Special architectural design and features must be developed for each project which often require research and thus resulting in higher cost.

|

Outstanding architectural design can be achieved at low cost using standard architectural details and interfaces.

|

|

11

|

BUILDING ACCESSORIES

|

Every project requires different and special design fro accessories and special sourcing for each item. Flashing and trims must be uniquely designed and fabricated.

|

Designed to fit the system with standardized and inter changeable parts. Including pre designed flashing and trims. Building accessories are mass produced for economy and are available with the building.

|

|

12

|

SAFETY AND RESPONSIBILITY

|

Multiple responsibilities can result in question of who is responsible when the components do not fit in properly, insufficient material is supplied or parts fail to perform particularly at the supplier/contractor interface.

|

Single source of responsibility is there because all the job is being done by one supplier.

|

|

13

|

FUTURE EXPANSIONS

|

It would be difficult to obtain project records after a long period of time. It is required to contact more than one number of parties.

|

All project records are safely and orderly kept in electronic format which makes it easy for the owner to obtain a copy of his building record at any time.

|

|

Future expansion is most tedious and more costly.

|

Future expansion is very easy and simple.

|

|

14

|

COST OF CHANGE ORDER

|

Substitution of hot rolled sections infrequently rolled by mills is expensive and time consuming.

|

PEB manufactures usually stock a large amount of that can be flexibly used in many types of PEB projects.

|

| |

Change orders that are made after the dispatch of hot rolled sections result in increasing the time and cost involved in the project.

|

Change orders are easily accommodated at all stages of the order fulfilment process. Little or no material is wasted even if a change order is made after fabrication starts.

|

|

15

|

PERFORMANCE

|

Components are custom designed for a specific application on a specific job. Design and detailing errors are possible when assembling the diverse components into unique buildings.

|

All components have been specified and designed specially to act together as a system for maximum efficiency, precise fir and peak performance in the field.

|

|

Each building design is unique, so predication, of how components will perform together is uncertain. Materials which have performed well in some climates may not do well in other conditions.

|

Experience with similar buildings, in actual field conditions worldwide, has resulted in design improvements over time, which allow dependable prediction of performance.

|

Disadvantages

- Marginal design, material and construction

- Not very energy efficient

- Higher lifetime maintenance

- Not durable for long term use, generally last 10 to 15 years

- May not include all construction/fit-up needed for the building to serve the intended purpose.

- No secondary roof membrane

- Usually no internal finished walls

- Subjected to higher degree of corrosion.

Conclusion

Pre-Engineered Metal Buildings are making a great headway into Indian realty with ready to assemble knocked down sets. The demand for Pre-Engineered Metal Buildings is growing in all scales in India. The demand for construction attracts an investment of more than USD 500 billion in next few years. The Industry size of Pre-Engineered buildings is USD 0.38 billion and the current Pre-Engineered Metal Building manufacturing capacity is appox0.35 million tonnes per annum. The market potential for PEB is approx1.2 million tonnes per annum.

The PEB industry in India is expected to grow, even considering the conservative estimate, at around 35% per annum.

- India still lags far behind the world average of 214.7 kg and China's average of 459.8 kg. The average is worse when compared with other Asian peers like Japan and South Korea at 506.7 kg and 1,156.6 kg, respectively.

- Private sector now accounts for 75% of total crude steel output compared to 37% in 1992-93 and 80% of total finished steel output compared to 67% in 1992-93.

- Based on the scientific model the estimated demand of fabricated structures is a sum of all sectors where it is utilized and hence adding them up we arrive at approx 50 lakh Tonnes in 5 year from 2012-2017 as follows: