Common Terminology in Water Proofing

Above-grade waterproofing- The prevention

of water intrusion into exposed structure elements through a combination of materials

or systems. These materials are not subject to hydrostatic pressure but are exposed

to weathering and pollutant attack.

Absorption- An Accumulation of water or moisture vapours

directly into a material’s structure of cells or fibres.

Accelerated weathering- Controlled conditions applied

in laboratory testing to condense greatly the weathering a waterproofing material

would experience over a long life cycle. Test results are used to compare materials

of different generic types or manufacturers.

Acrylic sealants - Factory-mixed, one-component materials

polymerized from acrylic acid. They are not used on joints subject to high movement

due to their relatively low-movement capability.

Adhesion - The ability of a waterproof material to

bond to a substrate or other material during movement or stress.

Adhesive failure - An after – installation failure

of the bond between a waterproofing material, such as sealant, to the substrate

surface.

|

|

Adhesive strength - The ability of sealants to bond

to a particular substrate, including adhesion movement or stress.

Admixtures - Materials added to masonry or concrete

envelope components to enhance and improve in-place product performance.

|

Adsorption- The surface absorption of waterproofing

system. Testing for adsorption is carefully controlled under laboratory conditions

to ensure uniform test results between different waterproofing materials.

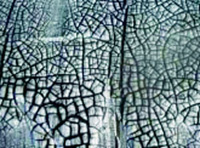

Alligatoring- The cracking that occurs on a waterproofing

material because of movement the material is not capable of withstanding. Alligatoring

also occurs when substrate movement begins before final waterproofing material curing.

Backing materials - Backer rods and backing tape that

prevent three- sided adhesion in joint design. When joints have insufficient depth

for backer-rod installation, tape is used at back of joints,

|

|

providing there is a firm substrate against which to install sealant. Backer rod

is installed in joints where there is no backing substrate. Backing material also

provides a surface against which to tool material and helps to maintain proper depth

ratios.

Bag grouting - Application of a cementitious waterproofing

material to the entire face of a masonry envelope. The cementitious material is

removed before it is completely set and cured by using burlap bags or stiff brushes.

This is also referred to as face grouting because the entire face of the masonry

facade is covered.

|

Barrier system - A building envelope component or

waterproofing system that completely repels water rather than diverting it.

Base flashing - Flashing that prevents water from

wicking upward in capillary action in a masonry wall.

Below-grade waterproofing- Use of materials that prevent

water under hydrostatic pressure from entering a structure or its components. These

systems are not exposed or subjected to weathering such as by ultraviolet rays.

Bentonite waterproofing- Waterproofing materials composed

primarily of montmorillonite clay, a natural material. Typically, bentonite waterproofing

systems contain 85-90 percent of montmorillonite clay and a maximum of 15 percent

natural sediments such as volcanic ash.

|

|

Blister- A portion of a waterproofing material raised

from the substrate because of negative vapour pressure or application over wet substrates.

Building envelope- The combination of roofing, waterproofing,

damp proofing, and flashing systems that act cohesively as a barrier, protecting

interior areas from water and weather intrusion. These systems envelop a building

from top to bottom, from below grade to the roof.

Butyl sealants- Sealants produced by copolymerization

of isobutylene and isoprene rubbers. Butyls are some of the oldest derivatives to

be used for sealant materials.

Cant- The angled or bevelled transition between a

horizontal and vertical substrate that provides for a smooth transition between

this change-in-plane details. Also refers to the application of waterproofing material,

such as cementitious coatings or sealants, applied at this intersection.

Capillary admixtures- Admixtures that react with the

free lime and alkaline in a concrete or masonry substrate to form microscopic crystalline

growth in the capillaries left by hydration. This crystalline growth fills the capillaries,

resulting in a substrate impervious to further capillary action.

Caulking - Joint sealing material appropriate for

interior joints that exhibit little or no movement.

Chemical cleaning- A cleaning method using a variety

of chemical formulations to remove a number of substrate stains including paint,

rust, and pollutants

Chemical grouts- Similar in application to epoxy injection

repair; however, these materials are manufactured from hydrophobic liquid polymer

resins. Chemical grouts are used for waterproofing cracks in a substrate and not

for structural repairs.

Cohesive strength - The ability of a material’s

molecular structure to say together internally during movement. Cohesive strength

has a direct bearing on elongation ability.

Construction joint- A Joint formed at the intersection

of two separate concrete placements.

Contaminants-Foreign material found on a substrate

such as oils, curing agents, dust, dirt, or rust.

Control joint-A joint in building or envelope materials

that allows for substrate movement.

Copings- A protective, waterproof covering placed

on the top of a structure such as a parapet wall.

Counter flashing- Flashing that is surface-mounted

or placed directly into wall with a portion exposed to flash various building elements,

including roof flashings, water- proofing materials, building protrusions, and mechanical

equipment, into the envelope.

Curing agent- A separate material applied immediately

after application to waterproofing materials or substances. Curing agents enhance

curing time and properties.

Damp proofing- A system that is resistant to water

vapour or minor amounts of moisture and that acts as a backup system to primary

waterproofing materials. Damp proofing materials are not subject to weathering or

water pressure.

Delamination - Separation of envelope materials from

the applied substrate due to movement or improperly applied materials.

Detailing joints- Joints required as a component or

part of complete waterproofing systems. They are used for water tightness at building

details such as pipe penetrations and changes in plane before application of primary

waterproofing materials.

Differential movement - A phenomenon that occurs because

materials have the individual characteristics of coefficients of movement that differ

from surrounding envelope materials or systems. These differences will cause the

materials to move at different rates during substrate movement.

Drainage systems- Prefabricated materials that facilitate

the drainage of water away from the building envelope.

Dual –cell foams- A backer rod that is comprised

of both open – and closed – cell structures.

Efflorescence- The staining and discolouring of masonry

walls created by water – carried acids and chemical.

Elasticity- The measure of a sealant’s ability

to return to its original shape and size after being compressed or elongated. As

with elongation, elasticity in measured as a percentage of its original length.

Elastomeric - An adjective describing the ability

of a waterproof material to return to its original shape and size after substrate

movement during expansion or contraction.

Elongation- The ability of sealant to increase in

length, then return to its original size. Limits of elongation are expressed as

a percentage of original size. A material with a 200 percent elongation, for example,

is capable of stretching to double its original size without splitting or tearing.

Epoxy injection- The injection of low-viscosity epoxy

materials into substrate cracks to restore the monolithic nature of the substrate.

These can be used on wood, concrete, masonry, natural stone, or metal substrates.

If additional substrate movement occurs, the epoxy may crack.

Expanding-foam sealants- These are composed of open-cell

polyurethane foam fully impregnated with a manufacturer’s proprietary product

formulation. These products include neoprene rubbers, modified asphalts, or acrylic

materials.

Expansion joint - A break or joint in structural elements

of a building that will continue to experience movement by thermal expansion and

contraction.

Exposed flashings - Flashings used in a variety of

methods and locations. They can be an integral part of a system, such as skylight

construction, or applied to provide protection between two dissimilar materials,

including cap flashings, coping flashings, gravel stops, and edge flashings.

Flashing- A material or system installed to redirect

water entering through the building skin to exterior. These are made from a variety

of materials including noncorrosive metals and synthetic rubber sheet goods. Flashings

are installed as backup systems for waterproofing or damp proofing systems. They

are also used for waterproofing material transitions or terminations.

Freeze-thaw cycle - The cycle of water freezing, and

subsequently thawing, related to building-related components.

Gravity feed: The movement of materials from

one location to another by force of gravity.

Gunite - Pneumatically applied, small aggregate concrete

or sand-cement mixtures, which are also referred to as shotcrete.

Hydration- The Process of adding water to cement,

sand and aggregate, to form a paste that cures, hardens, and shrinks to create the

finished concrete or masonry product. During curing, water leaves this paste through

a process called dehydration, which causes formation of microscopic voids and cracks

in concrete. Once formed, these voids allow water absorption through the material.

Hydraulic cement- Frequently referred to as “hot

patch” materials, because of the heat generated during their extremely fast

cure cycle. These materials are used to patch substrate cracks and small areas experiencing

water leaking under hydrostatic pressure.

Hydrophilic- The chemical properties that attract

of absorb water.

Hydrophobic - The chemical properties for repelling

or diverting water away from a material or substrate.

Hydrophobic expansion systems - Systems combining

hydrophobic resins with synthetic rubber to produce hydrophobic expansion seals.

The term hydrophobic refers to materials that swell in the presence of water. Thus,

these materials require active water pressure to become effective water barriers.

Hydrostatic pressure- Pressure applied to envelop

materials by various height of water at rests.

Infiltration - Ingress of water,

moisture, vapour or air into a building envelope.

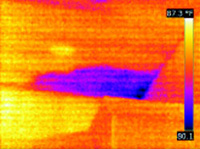

Infrared thermography: A non-destructive testing

method for locating delaminations in pavements and bridge decks and detecting moist

insulation, concrete, and wood in buildings; the presence of flaws within concrete

affects the heat conduction properties of the concrete and the presence of defects

is indicated by differences in surface temperatures when the test object is exposed

to correct ambient conditions. In the waterproofing industry it is typically used

to detect moisture behind closed walls by detecting evaporative moisture cooling

(EMC).

Isolation joints - Joints that allow for any differential

movement that will occur between two materials at junctures of these materials.

For example, window frame perimeters require isolation joints when abutting other

facade materials. These joints allow for differential movement at such locations

as changes in structural components (e.g., spandrel beam meeting brick facing material).

Joint grouting- Application of cementitious grout

to all surfaces of existing mortar joints, to repair the structure and waterproof

effectively.

Laitance - A thin layer of un-bonded cement paste

on concrete substrate surfaces that must be removed before waterproofing material

application.

Latex sealants-Typically, acrylic emulsions or polyvinyl

acetate derivatives. Latex materials have limited usage for exterior applications.

They are typically used for interior applications when a fast cure time is desired

for painting.

Membrane-A flexible or elastomeric waterproofing material

applied to a building envelope.

Millage - A unit for measuring the thickness of waterproofing

products. One mil is equal to one-thousandth of an inch.

Modulus- A measure of stress to stain; measured as

tensile strength, expressed as a given percentage of elongation in pounds per square

inch (1b/in2). Modulus has a direct effect on elongation or movement capability.

Moisture content Movement- Movement caused by certain

materials, particularly masonry substrates, swelling then subjected to wetting and

subsequent drying. When this movement is calculated as an aggregate total of the

entire façade area, it can be considerable.

Negative waterproofing- Below-grade waterproofing

systems applied to the interior or negative side of a structure, away from direct

exposure to groundwater.

Organic-A product comprised or manufactured of hydrocarbons,

plants, animal, or their derivatives.

Out gassing- The deterioration of a closed-cell backer

material that causes the sealant material to improperly cure and often leads to

failures.

Overlays- Cementitious materials used for restoring

deteriorated horizontal concrete substrates.

Parapet flashing- Flashing installed at the base of

a parapet usually at ceiling level. It is also used on the roof side of parapets

as part of roof or counter flashing. See Flashing.

Perm - The rate of water vapour transmission through

a substrate or material of one grain per hour per square foot per inch of mercury

pressure difference.

Permeability -The ability of a waterproofing material

or substrate to allow the passage of water vapour through itself without blistering.

Ph-The chemical measurement of a substrate’s

alkalinity or acidity.

Polymer concrete- A modified concrete mixture formulated

by adding natural and synthetic chemical compounds known as polymers. Although the

priority chemical compounds (polymers) vary, the purpose of these admixtures is

the same. They provide a dense, high-strength, low-shrinkage, and chemically and

water-resistant concrete substrate.

Polysulphides-Materials Produced from synthetic polymers

of polysulfide rubbers. Polysulphides make excellent performing sealants for most

joint uses.

Polyurethane- Any of various polymers that are produced

by chemical reactions formed by mixing di-isocynate with a hydroxyl, and are used

in making flexible and rigid foams, elastomers, and resins. Many types of polyurethane

are moisture-cured materials reacting to moisture in atmospheric conditions to promote

curing. Other polyurethanes are chemically curing mixtures.

Positive waterproofing-Waterproofing systems applied

to substrate side with direct exposure to water or a hydrostatic head of water.

Pot life-The length of time a waterproof material

or system is workable or applicable after having been activated.

Poultice- An absorbent material such as tale or fuller’s

earth that is applied to the envelope substrate to remove dirt the staining. The

poultice absorbs the staining and dirt into itself, and then is removed by water

pressure cleaning.

Primer-A separate material, usually in liquid form,

applied to a substrate before actual waterproofing system application. Primers enhance

adhesion properties of the water proofing system.

Protected membrane-A membrane applied between a structural

slab and topping slab or other top layer protection such as tile. The topping slab

or protection slab protects the membrane from weathering and traffic wear. This

is also referred to as a sandwich membrane.

Protection Layer-A layer of rigid or semi-rigid boards

or sheets installed directly over a waterproofing system application to protect

the waterproofing material from damage during back-fill or concrete placement operations.

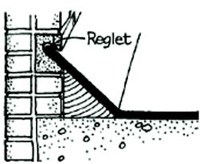

Reglet -A formed or sawn groove in substrate (usually

concrete) providing a transition point for two adjoining waterproofing systems.

Sealant - A material applicable to exterior building

envelope joints. Sealants are capable of with standing continuous joint movement

during weathering conditions without failing.

Shear movement-Lateral movement in a substrate.

Sheet expansion systems-Systems manufactured from

neoprene or hypalon rubber sheets. Joint expansion and contraction is made watertight

by installing these materials in a bellows or loop fashion.

Shelf angle-Steel angle extrusion used over envelope

openings to support masonry and precast and other cladding materials.

Shelf life-The maximum time that packaged and unopened

waterproofing materials can remain usable.

Shore hardness-A measure of resistance to impact using

a durometer gage. This property becomes important in choosing sealants subject to

punctures or traffic, such as horizontal paver joints. A shore hardness of 25 is

similar to a soft eraser: a hardness of 90 is equivalent to a rubber mallet.

Silanes -Water repellents that contain the smallest

molecular structures of all silicone – based materials. The small molecular

structure of the Silanes allows the deepest penetration into substrates. Silanes

must have silica present in substrates for the chemical action providing water repellence

to take place. These materials therefore are inappropriate for substrates such as

wood metal, and limestone.

Silicone rubber-A water repellent manufactured from

silicone elastomers that has a millage usually greater than other silicone-based

sealers.

|

Silicone water repellent-water repellents manufactured

by mixing silicone solids (resins) into a solvent carrier. Most manufacturers base

their formulations on a 5 percent solids mixture, in conformance with the requirements

of federal specification SSW-110C.

Silicones-Silicone sealants are derivatives of silicon

polymers produced by combining silicon, oxygen and organic materials/ Silicones

have extremely high thermal stability and are used as abrasives, lubricants, paints,

coatings, and synthetic rubbers. See Sealant.

Sodium silicates-Materials that react with the free

salts I concrete, such as calcium or free lime, making the concrete surface more

dense. Usually these materials are sold as floor hardeners.

|

|

Spall/spalling-The crumbling or breaking off in small

pieces of a concrete or masonry substrate, usually owing to freeze thaw cycles or

deterioration (rusting) of embedded structural elements such as reinforcing steel.

Substrate - Structure or envelope components to which

waterproofing materials or systems are applied.

Surface tension: A phenomenon caused by the attraction

of molecules to like molecules. As molecules on the liquid surface are not surrounded

by the same molecules on all sides, there is a resultant increase in their attraction

to neighbouring molecules on a surface.

Swale: A shallow trough like depression that

carries water mainly during rainstorms or snow melts.

T-joint system - A sealant system reinforced with

metal or plastic plates and polymer concrete nosing on each side of the sealant.

This system derives its name from a cross section of the joint, which is in the

shape of a T.

Tackiness-Stickiness of a waterproofing material’s

exposed surface after installation or during its final curing stage.

Tensile strength -The ability of a waterproofing material

to resist being pulled or stretched apart to a point of failure.

Thermal movement - Movement, either expansion or contraction,

caused by temperature changes.

Thixotropic paste: Paste used to anchor injection

T-ports to the wall which acquires a lower viscosity when mechanically agitated,

and rapidly stiffens upon subsequent rest; a material having this property can be

placed vertically or horizontally without sagging during the curing process. This

is the type of paste used for low pressure crack injections of epoxy and

polyurethane resins.

Tooling- The means of finishing mortar or sealants

that have been applied into envelope joints.

Tuck-pointing -The repair of existing mortar joints

in masonry walls by removing the old material and filling with new mortar.

Ultraviolet-A form of light energy positioned in the

spectrum of sunlight beyond violet, the limit of visible light, that is an especially

detrimental weathering condition to above-grade waterproofing materials and envelope

component.

Viscosity -The chemical property of liquid waterproofing

materials to resist a change in shape.

Water cleaning-A building cleaning method incorporating

water by pressure, soaking, or steam to remove dirt and pollutants from a substrate.

Water penetration / Infiltration -The circumstance

in which water accesses the interior areas of a building envelope.

Water-stops-Preformed materials placed between construction

joints in separate concrete placements to prevent passage of water between the joints

that forms at this intersection.

Weep hole-Opening in a masonry wall or sealant that

allows the escape of water entering envelopes to the exterior. Exiting water is

collected by a combination of damp-proofing and flashing materials.