SYNERGY THRISLINGTON

Completes 10 Storey building in 48 hours

|

Introduction

Synergy, a 1000 Crore well heeled Infrastructure Company, laid its footing in 1987 in Mohali (India) and from the very beginning, company’s specialization has been in the business of precision Sheet Metal Fabrication as manufacturers to provide solutions in the field of Telecommunication, Healthcare & Hospitality, Defense and Pharmaceuticals etc.

With the amazing work culture and distinctive insight, SYNERGY GROUP took over UK based Thrislington Products Limited (One of the oldest re-locatable steel partitions manufacturers in United Kingdom founded in year 1946).

The entity SYNERGY THRISLINGTON manufactures Pre fabricated buildings, Factory made Modular Buildings, Factory Made

|

Completed INSTACON - Red and White Structure.

|

modular houses, Puf Panels, demountable office partitions, fire rated / non fire rated doors, clean rooms, ceiling panels etc.

To its accreditation and prestige, Synergy joined hands with Marriott International in 2011, to setup JW Marriott Chandigarh - a five star luxury hotel successfully providing upper crest hospitality in the region.

Synergy's reputation and feat is based on our knack to be receptive and performing, meeting the needs of the client in terms of quality, time line and budget. We pride ourselves on our panache to realize client's requirements and connect with them through each and every step of our process. Their product portfolio includes;

- Factory Made modular Housing projects (Instahome)

- Factory Made Modular Steel Buildings (Instacon)

- Prefab Structures using PPGI PUF Panel Sheets catering to requirement of Site Offices/Porta Cabins/Labour Colony etc. Infact recently, we had accomplished 1 Lac Square Feet Area in 100 days (Turn Key) for SRM University at their Sonipat Campus in record time of 100 Days.

- Fire/Non Fire Rated GPSP Doors and Partitions for Various Requirement

INSTACON

|

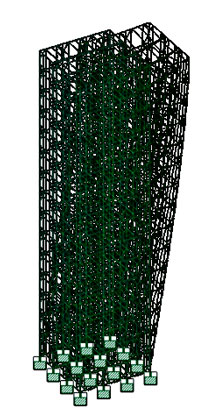

Scaled model of the G+7 framed structure on the shake table

|

"A revolutionary building concept made realistic for the first time in the history of India where we constructed a multistory building in 48 hours ie highly reduced construction time of a conventional building."

INSTACON is an ultra fast modular Building Solution manufactured in a controlled factory environment and shipped to a prepared building site for installation. Each building is code compliant and meets the strictest building norms. INSTACON construction is an alternate but instant method of building in commercial applications such as Hospitals, Office spaces, Schools, Universities, College, Hostels, Multi-storey Towers, commercial complexes, Housing projects etc.

INSTACON construction uses factory techniques to improve quality, shorten construction time, and reduce cost. By using a closed factory environment to manufacture each building, the benefits are increased worker efficiencies, economy of scale, reductions in delays due to inclement weather or vandalism, which adds up to greater speed at less cost to you.

|

CSIR-SERC AnalysisM/s Synergy Thrislington approached CSIR-SERC for Seismic Performance Evaluation of Cold Rolled Steel Framed Structures and the laboratory analysis was based on Shake table experimental studies with different spectra and Analytical studies.

|

Scope included Analysis of the Cold Rolled Steel framed structure for the seismic load as per IS code, evaluation of the seismic performance of model for a ground motion compatible to Zone V Spectrum as per IS: 1893-2002 and study of the damage pattern/ suggestions for improvement.

|

|

INSTACON-Unique Features

- Ultra fast Construction: India's First factory made building. Above 80 % of the work finished in factory, our HIGH EFFICIENCY MODE of Construction enables us to deliver completed building in few days of work at site.

- Energy Conservation: Through its technological advancement features, INSTACON ensures 1/5th of the energy consumption as compared to a conventional building system.

- Earthquake Resistant : Tested & Certified by CSIR- SERC, Chennai for its seismic responses, these can withstand earth quakes till seismic zone 5,which is the highest earthquake intensity zone in India

|

Erection Work In Progress

|

|

"In order to apprise the world of this technology, We have erected a Instacon ( G+ 9 ) sample Building at our Mohali Corporate Office ( A-1, Phase-I, Industrial Area, Mohali ,India) in 48 hours and showcased mock ups of Hospital, Hotel, college, hostel and Office spaces on different floors."- An unmatched feat achieved; recorded in Limca book of records as fastest building so far in history of India

The Story

In a remarkable feat, unparalleled in India, a dumb-struck audience witnessed the completion of a factory-made ten floor high rise in Mohali, on 29th November, 2012, which is constructed in recorded 48 hours, a feat that gave them an entry into Limca Book of National Records. The project was inaugurated by S. Sukhvir Singh Badal, Honourable Dy. Chief Minister, Punjab.

Addressing media persons later in the evening, Harpal Singh said the cost of the construction of this building was comparable to the cost of construction of normal buildings that used bricks and cement. 'This is a nut-bolt tubular structure and considering the time element and the cost of construction material required in a normal building this is a much more cost effective venture. However for smaller houses like kothis it will not be cost effective. However, if many smaller buildings are to be made, it will work out to be an economical venture,' he said.

|

Deformed Shape of G+14 Storey Frame

|

|

I C Syal, an ex-professor of Punjab Engineering College here who designed the building, said the structure can with stand For 600 years. "It's a tube-in-tube structure. There will be no problem of seepage or leakage in this building. We also measured building's deflection in case of strong winds and earthquakes, which comes to 49 mm as against 123 mm deflection allowed by the government for conventional buildings," Syal said.

|

|

| The process to construct the 10 floor “INSTACON”, in 48 hours was started with 3 cranes, 200 plus, highly skilled technicians and workers and a slew of video cameras from all corners for the purpose of capturing the unprecedented happening event. Steel structure floors with the outer insulated walls were put together and the process continued round the clock to assemble the 10 storey structure in 48 hours, the target successfully achieved within the stipulated time period.

|

|

Speaking on the completion of construction work,COO Synergy Thrislington Yashjeet Gupta pointed out, "This construction mechanism has been approved by the Council of Scientific and Industrial research(CSIR)-Structural Engineering research Centre (CSIR-SERC), Chennai. The model has also been cleared for the Zone V seismic area which is the highest."

He said, "The ultra fast mechanism helps save energy in quantums in comparison to traditional construction methods. One can get revenues from the investment within days. Though the cost is almost the same as incurred using Conventional techniques, there is lot of gain in saving man-days of work and terms of manpower days and overcoming inflationary increases".

"We have moved the construction from site to factory." "The construction industry will immensely benefit from this and will solve many problems. Our buildings will be safe and building them would be quick and Economical. They will have low energy consumption and CO2 emissions," he added.

| This technology as it unfolded today has vast potential to totally revolutionize the much-needed Infrastructure Technology in the country by rapidly speeding up the construction of Commercial towers, Luxury hotels, High-rise buildings, Hospitals, Educational institutions, Universities, Retail outlets & residential projects. |

|

| The construction technology, first of its kind in India, is unique in many ways. All the components of the building are manufactured in the factory, pre-fitted with floors, water supply, wirings, sanitation, air conditioning ducts and everything else. These are then shifted in state-of-the-art transporting vehicles to the actual site for installation. More than 80 percent of the work is done in the factory.

Concrete is used only in foundations and 3-inch deck floorings in this nut and bolt structure, thereby minimizing the usage of concrete. Surprising as it may sound, but no scarce resources like "bricks", "sand" or "gravel" is used. Since it is an ultra fast technology of construction with less than 20 percent of work at

|

|

site, there are minimal emissions of flying dust and less pollution of water at site. The external façade of the building is double-skinned PUF panel that ensures thermal insulation. Minimised Environmental wastes and pollution: With total quality control at plant and less than 20 % of work at site, there are minimal emissions, flying duct, polluted water at site. Construction waste reduces to 1 % of the total material involved.

- Improved Air Quality: With the use of advance systems for improved air quality, INSTACON ensures 20 times cleaner air as compared to outside.

- Safety of construction: with around 20% work of the whole project at site, we deliver highest levels of safety for our projects.

- Cost Savings & return on Investments: Ultra fast construction mode is a cost saver. It Provides Reduction in financing cost by earlier return on initial capital, quicker & higher income from rentals, zero material wastage & increased asset value.

- Quality design & engineering along with Synergy’s assurance.

- Facade of the building is double skinned PUF panel that ensures thermal insulation

- Target in assembling 200 tonne building having an area of over 25,000 square meters