Construction and Erection Deficiencies

Often, the design is fine, but the contractor finds he cannot implement parts of it. Technically, the contractor should bounce the ball back to the designer explaining his difficulty so that the designer can either revise his design or advise a practical method of achieving his ends.

The tendency of contractors though is to substitute the impossible design with a feasible alternative, with or without a rigorous analysis by their own competent person, particularly on how the substitute design component fits into the overall design which the original designer had submitted. Many accidents are on record due to this non- or mis-communication between designer and contractor.

Things are changing. The high costs of accidents have forced formerly separate entities to share mutual concerns, before tragedy hits. Many standards have adopted the 'Design for Safety' and 'Life Cycle Design' approaches whereby the designer is expected at least to highlight hazards and difficulties in the implementation of the design details.

1. Skyline Plaza Apartments, USA, 1973

Around 2.30pm on March 2, 1973, the Skyline Plaza 26-story apartment building in Bailey's Crossroads, Virginia collapsed while under construction, at the rate of one floor per week, except that recently, the pace had been accelerated, so that when the concrete was being placed for the 24th floor, the 23rd floor slab was only four days old instead of seven days, [12]. This was against the local Code. (Figure 7.)

|

The collapse killed fourteen workers and injured 34. It was found that while full shoring remained on the 23rd and 24th stories, it had been removed from 22nd story in about three-fourths of the area. Thus relieved of its previous loads, slab deflection of the 22nd story would have decreased, causing its re-shores underneath on the 21st floor also to fall out. Construction did not adhere to the engineer’s stated requirements: "Slab being poured to be shored for two floors and back-propped at center of span each way and at center of bay on next floor down." or the architect's specifications requiring "in all cases, two floors shall be fully shored".

|

|

Probable cause of the collapse was a punching shear failure of the 23rd floor, caused by the premature removal of forms supporting the 23rd story slab, resulting in the shear stresses exceeding the concrete capacity at the time of the incident. The accumulation and impact of falling debris from the collapsing 23rd and 24th floors overloaded the 22nd floor slab and induced the progressive collapse of successive floors down to the ground.

Average air temperature was 6 - 7°C, at which, concrete takes twice as long as in a laboratory to gain strength. Field-cured concrete cylinders should have been used rather than laboratory cured cylinders to ensure that the concrete had achieved sufficient strength before removing shores and forms.

The concrete subcontractor paid less than $20,000 in fines, despite the fact that the collapse had caused $8 to $10 million in damages, in addition to the deaths and injuries. The architect and engineer, sued by one injured worker, were held responsible for the collapse, even though their explicit specifications for required shoring were not implemented at the site, and they had to pay his claim of $250,000 - ironically, this last was because it violated the requirement at the time that the designers had a responsibility to inspect the work and warn those involved of any unsafe conditions.

2. The Chicago City Post Office

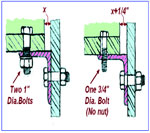

Fig. 8. Left - As designed, and Right - As erected

| On November 3, 1993, a portion of Chicago's new main post office under erection, collapsed, killing two ironworkers and injuring five others. At the time, workers were laying beams in place before fastening them. One of the insecure beams caused the collapse by creating a chain reaction and pulling down 60 to 70 other already erected steel members. The beams that collapsed were 32 ft (9.75m) long and weighed four and a half tons (45kN). |

|

|

Root cause was traced to the changes made by the fabricator in the erection procedure, solely for ease of erection, resulting in the beams being placed 1/4 inch (6mm) farther away from columns than required. (Figure 8.)

|

This change made the use of the 1 inch diameter bolts impossible. Instead, workers had to use 3/4-inch bolts to secure the beams. This change in hardware led to a series of weak connections, some without nuts to secure bolts. Unsurprisingly, the location where collapse began was a connection where a nut was not used. All this havoc for just a 1/4-inch shift of a temporary support, and a 1/4-inch thinner bolt!

3. Hartford Civic Centre Arena Roof Collapse

Another classical case where the erector modified the designer's connection and caused structural collapse was the Civic Center Arena in Hartford, Connecticut, USA, completed in January 1973, designed for first time by a 3D truss analysis computer programme.

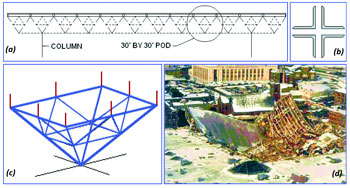

As shown in Fig. 9, the 300 ft. by 360 ft. (91m by 110m) roof space frame consisted of pods in 30 ft. by 30 ft. (9.1m by 9.1m) grids, 21 ft. (6.4m) apart, made from members in the shape of a cross – which unfortunately is a most inefficient shape for bending and buckling.

On January 18, 1978, the largest snowstorm of its five-year life hit the arena. Early morning, the centre of the arena's roof crashed down 83 feet to the floor of the arena, throwing the corners up into the air. Luckily the arena was empty.

|

Fig. 9. Hartford Civic Center Arena, Sections and Collapse

|

Table 2 Comparison of (a) As designed, and (b) As-built connections

Cause of the collapse was traced to relatively minor changes in the connections between steel components, with the fabrication deviating from design. The most frightening result of the changes was in a particular connection in which a few centimetres shift of the fabricated connection cut down axial force capacity to less than a tenth of the design value. (Table 2.)

The designers should have checked whether their proposals could be translated into practice. Alternatively, the fabricator should have had the designers check and approve the changes he was proposing for practical reasons.

As in many other cases, the structure itself gave ample warnings of impending failure by excessive deflection, which were ignored.

The designers too were over-confident about the computer programme which at that time had not considered all buckling modes, and ignored the large deflections during erection.

The collapse triggered a complete nation-wide review of similar structures and of computer applications, and resulted in upgrading the safety aspects in design.