Construction Supply Chain Management

For Reengineering Construction Industry

|

Mr. Madhukar B A, MD & CEO of Potential Project Manager Pvt. Ltd., in an interview with Built Expressions clearly outlines that Supply Chain Management (SCM) as a science and tool can help a construction company in scaling up the operations and bringing in a system & process-based approach to what is traditionally an intuitive one-man or two-man process within the company. |

BE: How far Indian Construction companies have adopted Supply Chain Management (SCM) in their business processes?

When compared to industries with mature SCM practices within India like Manufacturing & Automobile, the Construction industry is lagging. Simple things like aligning suppliers & sub-contractors to the business vision and treating them with a long term view is now being thought of whereas the same is fundamental to setting shop in other industries. It makes good business sense for both the companies requiring goods & services and the providers of these to look at each other as an integral part of the eco-system and accept the need to do business with each other perpetually for mutual benefit & good of society. This is at the core of effective supply chain management.

|

Very few companies have acknowledged the importance of supply chain in their business strategy and at business model level creating weak links in the chain. Examples can be cited of very large companies being in business for decades and still struggling to have a decent set of architects, consultants, suppliers and sub-contractors who can be relied upon to provide timely, cost-effective and efficient support system in the development of a project. This is not limited to just Project Development companies but encompasses the entire eco-system. Architectural / Consultancy firms who do not have efficient supply chain to meet their needs of hardware, software & consumables and Contracting companies with very weak linkages with their suppliers &sub-contractors for their requirement of equipment, materials &labor. So far as adoption is concerned, in my interactions with dozens of companies all over, it is very sketchy and elementary. The subject has not been approached as a science to be allocated resources for implementation& having direct management review. It is more taken as a part of internal compliance limited to some static pre-qualification forms that neither reflect the most important points of consideration nor updated periodically to reflect performance over a period of time.

|

Not much thought seems to have gone into designing the system of vendor evaluation, performance appraisal and rating mechanism which are essential for an effective supply chain management strategy. I have not seen an end-to-end system in place with processes, procedures and monitoring & control systems. Lastly, there is no mechanism in place to evaluate vendor performance, do a thorough root-cause analysis and arrive at improvement measures to be put in place in the vendors (and in the sponsor) and ensure effective implementation leading to continuous improvement of the eco-system. In my view, it is this incremental improvement either in cost, quality or timelines that is the end result expected of an effective supply chain management system that is missing in our system. I am not saying that we, as an industry, have not done much but that there is more to be done when compared with best practices.

|

BE: What is SCM in construction segment? Which are the elements of construction that are comprised in SCM?

Here is an attempt to represent the basic framework or requirement of an SCM in our industry which is a cyclical process involving perpetual iterations over the lifetime of a company and its vendor network. This iterative process represents the generic model for any goods or service that a company intends to procure. This is part of the total quality management system that the Japanese have implemented in many of their organisations.

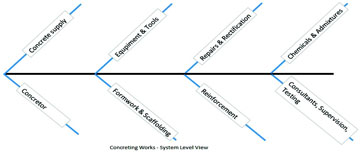

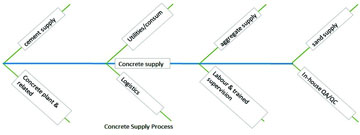

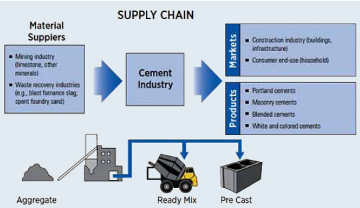

When specifically applied to our industry, for example, on concrete, which is a byproduct of both goods & services in its chain, the following can be illustrated:

As can be seen, there are innumerable chains & sub-chains within the general work of concreting. Any optimization in the key parameters of cost, quality & timelines must come from any of these sub-processes. We are seeing some kind of sub-assembly level activity taking place at the current Ready Mixed Concrete Plants which is taken as an example here. At this level, specialized agencies come into picture who have their own eco-system of designers, fabricators, suppliers and service providers and it is generally deemed that these RMC suppliers have streamlined their supply chain to optimize their product delivery. The effectiveness or otherwise of these supply chains between the RMC makers is played out in the market place where one competes to out beat the other, be it in quality of finished product, effective delivery or cost.

While at first glance this may sound like common sense and presumed as given, one would be surprised when you deep-dive into any of the processes or sub-processes and realize the vast gap between perceptions and actual practice. In large projects or when these goods &services are seen as a perpetual part of one’s business, these factors become critical while determining the competitive edge of say Developer A vs Developer B and or Contractor X vs Contractor Y and so on. Keeping this long term view of business and maintaining competitiveness, it is prudent to have a system of supply chain management in place which can deliver value over a period of time. I am not for a moment saying that this is non-existent now. Instead, we need to move away from the current practice of making decisions based on intuition & experience and towards one based on understanding of the eco-system as a whole and running data driven metrics developed over a period of time. This is the gist of the SCM that I believe will mitigate the impact of risks associated with each of the sub components on the whole delivery system in our industry.

BE: There are numerous inevitable complexities and fragmentation that are involved in the entire construction process right from procurement of materials to completion of projects. In such a scenario, what are the issues involved in the traditional management (without SCM)?

J&M's End-to-End Value chain Approach

This is a good question. The obvious answer would be our inherent inertia for change and the love of the comfort zone one is in. Without a periodic & systematic evaluation of the process involved in procurement of goods & services for a company, one cannot see significant improvement in either the quality or the cost of the outsourced delivery. While other industries have implemented these practices for a long time, our industry is not giving importance to this mainly because of lack of buy-in from top management which needs to set the direction for long term improvement by allocating resources and focus for sustained durations. After all, Mercedes Benz or Ford did not happen overnight. Systematic review of current practices and junking those that are not in sync with the stated objectives of optimization is the need of the hour for companies big & small that are spending significant amounts on procuring outsourced goods & services. Some of the companies spend as much as 80% of their cost on other companies outputs and it is important that this is looked at closely more so from current trend which is towards outsourcing everything but the core expertise.

Further, our industry still runs on long term relationships or dealing with known entities. Word of mouth plays a significant role in the decision-making process. We are averse to taking anything that is not seen, felt or experienced. This is slowly changing with wide-spread use of internet & mobile phones and process based approach.

Lastly, the traditional management never looked at aggregating their requirement over a period of time, say for 12 or 6 months, and use that power to negotiate for a medium term or long term association with their supply chain. I have seen many large companies still placing orders for concrete or steel on a project-to-project basis rather than aggregating their requirement say over several projects based on their historical requirements or anticipated growth. This, in effect, means, both the vendor & the sponsor look at each other from an arm’s length rather than a handholding or collaborative spirit for mutual good that is at the heart of effective SCM. Every time, there is a bidding process for that piece & parcel of the package, extensive negotiations are carried out wasting transaction time that could be avoided. I have seen several vendors servicing for a product in different projects and many a times multiple suppliers supplying same product within a project. This practice, while aiming to hedge the risks involved in failure of the vendor, ignores the basic tenets of economy of scale, larger share of a vendor’s business, and leverage in terms of favorable payment terms. In my opinion, these are important aspects &outweigh the other perceived benefits.

Looking at it from a vendor or seller’s perspective, it makes good sense to sign off at a lower price for a larger committed volume which can assure more predictable production lines and lesser inventory rather than put up with vagaries of supply & demand that plague any industry.

BE: Are there any separate SCM models for construction process, if so, which are those models?

|

To my knowledge, there are no off-the-shelf SCM models that are available to suit our industry, let alone the ones tailored for Indian conditions. We have, over the last couple of years, worked on some 30 odd processes wherein the supply chain can be vastly streamlined giving immense value to both sides of the eco-system. With this as a back-bone along with a robust web-enabled platform, we have managed to develop a data base of about 400 providers of goods & services from India and abroad. The exercise of benchmarking & evaluation is ongoing so it will take some time. We are looking for more volunteers to be part of this exercise. The challenge is complicated by the need of each company to maintain strict confidentiality with regard to its vendor base (& its performance) which it considers proprietary. So, in effect, even though many companies are working on strengthening their supply chains and bringing robustness to their existing linkages, not much improvement at ground level is seen. My view would be a hybrid between what is being practiced in the other industries like automobile, manufacturing & IT rather than a lock-stock-and-barrel clone of the current practices from these industries.

Due to the obvious differences in deliveries within our country, there is no single best practice that can be created. In a way, there is no one-size-fits-all model or solution that can fit the SCM requirements of any company on a pan India basis. Understanding the underlying values, practices and criteria form the basis of any model that is to be created for a specific company or industry sub-category and then fine-tuned to reflect the geographical or local eco-system considerations.

BE: What are the barriers associated in integrating SCM?

The biggest challenges that we face today in integrating SCM into existing practices are

- Uncertainty over the effectiveness or otherwise of implementation

- Lack of proven model of cost, quality or other improvement by implementing SCM for our industry – no case studies exist, to my knowledge

- Lack of top management buy-in and hence resource allocation

- Resistance to web-enabled technologies

- Resistance to change in the processes involved in current intuitive, person driven practices to incorporate the much more transparent, value driven SCM approach

- Our inability to shift focus from solving day-to-day problems to setting aside time & effort for providing a lasting strategic shift for decision makers & users

BE: In what way, a typical construction company would benefit from adopting SCM over traditional management?

In a way, SCM (or for that matter, any other concept or practice) is not a cure-all for the many ills that are plaguing our industry. Nor could it be said that the traditional management is less beneficial than SCM. Let’s accept that our construction companies doing business successfully for so long. However, SCM as a science & tool will help one in scaling up the operations and bringing in a system & process-based approach to what is traditionally an intuitive one-man or two-man process within the company. We can do so by the following:

- Controlling uncertainty by longer term engagements

- Reduced inventory stockpile due to better or predictable demands and tracking vendor performance

- Metric-driven and transparent evaluation criteria leading to improvements for all in the eco-system and not just the sponsor or the vendor

- Every vendor will have equal opportunity to compete to sell his goods or service as against the traditional model where you need to know or be in the good books of so & so to get an order.

- Aggregating orders or booking production lines in advance leads to cost reduction

This will eventually lead to wider choice for the buyer of goods & services, and final user benefits.

B A Madhukar

B. A. Madhukar is a graduate Civil Engineer from Bangalore University.

He has more than 26 years of experience in India and Abroad working on all types of construction projects ranging from Roads to High-rise Buildings to Tunnels & Underground MRT Stations. He has worked in Singapore for about 12 years out of which he has worked for more than 7 years in SembCorp Engineers & Constructors Pvt Ltd, one of Asia’s leading Engineering & Construction companies.