High Performance Buildings

'High Performance Buildings' in India can be defined as buildings that have integrated bioclimatic solar passive architectural design strategies and energy efficiency measures as recommended by Energy Conservation Building Code-ECBC. High Performance Buildings-HPB's are also referred to as Green Buildings, Sustainable Construction, and Ecological Design etc.

Design considerations and Energy Conservation Measures strategically vary from place to place as functions of climatic parameters. India has been divided into five climate zones- Hot and Dry, Hot and Humid, Composite, Cold and Moderate. HPBs designed under these varying climatic conditions will also exhibit varying energy efficient features depending on the type of building. Figure 1 shows the climatic zones of India.

Basic Principles

High performance buildings are designed and operated to meet specific standards for energy consumption, water use, system reliability and uptime, environmental performance, indoor air quality, noise levels, occupant health and comfort, and other mission essential factors. For example, providing a productive environment for its employees is one of the goals of Godrej Bhavan, which recently completed a project to improve the performance of its building at Fort, Mumbai. With heating, ventilating and air conditioning (HVAC) system upgrades, web-enabled building controls and other improvements, the company created a better environment for employees while reducing annual energy costs. The building became the first in the city of Mumbai to earn Gold certification from USGBC in the existing building (EB) category.

Operating standards are set, measured and continually validated to deliver established outcomes within specific tolerances. The standards vary depending on an organization’s mission. For example, a hospital would likely set different acoustical and indoor air quality standards than a school, which would have different standards than an office building or factory.

Energy Scenario in India1

Energy Conservation Building Code (ECBC) in its continuous endeavour to bring in awareness, conducts regular training programs. As per ECBC data provided in its training module document, some salient features in respect of energy scenario in India are listed below;

-

16% of Global Population.

-

Installed capacity in India-approx. 160,000 MW

-

Projected Capacity in 2030- approx. 800,000 MW

-

4.5% Compound Annual Growth Rate (CAGR) in primary energy demand (1997-2007).

-

Capital investment needed on supply side- approx. $ 1 Trillion.

-

66% of India’s Commercial Buildings Stock in 2030 has not been built yet.

-

No other country in the history would have encountered the growth in the AC load that India is poised to experience.

-

Capacity added by China in the last two years- 180,000 MW

Basic Design Considerations

Following are some the basic attributes to be considered while designing a High Performance Building.

Technology -enabled and knowledge-based approaches that are holistic in nature form the basis of high performance buildings. Intelligent services continuously monitor critical building systems and use sophisticated analytic and diagnostic tools to identify potential problems and enable building owners and operators to make real-time decisions. Advanced technologies with focus on energy efficiency, sustainability and cost factor enable HPBs to perform better.

Features and Benefits3

As per 'HPB Guidelines-Department of Design and Construction New York', the following design, construction, and operation activities can result in value-added public buildings. Direct, indirect, and 'external' benefits are briefly identified and discussed.

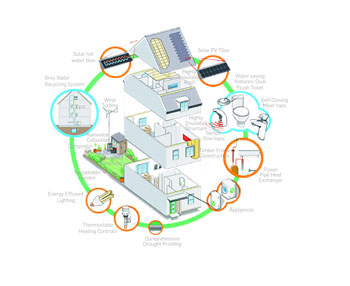

Actions: Reduce energy use and demand through passive solar techniques and integrated building design. This process looks at optimum sitting / orientation and maximizes the thermal efficiency of the building envelope (windows, walls, roof) while considering the interaction of the HVAC, lighting, and control systems. Integrated design uses daylight to reduce electrical demand, and incorporates energy efficient lighting, motors, and equipment. It encourages 'right-sizing' of mechanical systems to avoid higher first costs. Where feasible, renewable energy sources such as photovoltaic cells, solar hot water, and geothermal exchange are used in tandem with other low emission technologies, such as fuel cells.

Benefits: Direct energy cost savings (fuel and electricity) and other life cycle savings yield a good rate of return based on the initial investment. Other external benefits include improved air quality from reduced fuel consumption (limiting nitrous oxide, sulfur dioxide, methane, and other gases that contribute to air pollution). Similarly, reducing the overall aggregate electrical load significantly reduces carbon dioxide emissions, the primary greenhouse gas implicated in global climate change.

Actions: Improve indoor air quality by eliminating unhealthy emissions - such as volatile organic compounds, or VOCs - from building materials, products, and furnishings, and through outside filtering and distribution techniques that control pollutants. Improve the thermal qualities and comfort levels of all occupied spaces. Maximize the use of controlled daylighting which can then be augmented by high quality artificial lighting. Provide good acoustic control. Wherever possible, offer occupant the ability to regulate their personal comfort.

Benefits: High performance facilities can help address a wide range of human resource concerns by improving the total quality of the interior environment. In addition, attention to building wellness today helps avoid future costs for correcting sick building syndrome. Such ‘well building’ design emphasis can improve occupant comfort, health, and well-being, in turn reducing employee absenteeism and turnover. The same benefits apply to the facility’s public users.

Actions: Where equivalent in quality, cost, and performance, use green building materials and interior furnishings that are made from recycled or renewable resources, are themselves recyclable, and that have been manufactured in a manner least damaging to the environment. Implement construction and demolition (C&D) waste prevention/management strategies and selective site sorting of materials for salvage, recycling, or disposal.

Benefits: These actions will prevent unnecessary depletion of natural resources and will reduce air, water, and soil pollution. They will also strengthen the market for recycled materials, and the manufacture of products with post-consumer content. Long-term, better C&D waste management can reduce waste disposal costs, ease stress on landfills, and minimize the cost of transporting waste to disposal facilities outside the City.

- Building Operations Resource Management

Actions: Design in ways that promote good building operations practices: conserve water using site- and facility-wide measures, create space for everyday waste recycling, and improve housekeeping practices through use of benign cleaning products and more efficient cleaning and maintenance protocols.

Benefits: Water conservation measures will help maintain New York City’s water quality and avoid potential future costs by reducing overall loads on water filtration and treatment systems. More efficient cleaning and custodial protocols may increase productivity of custodial staff, while improved housekeeping measures will contribute to overall occupant health and well-being.

Energy Conservation Building Code (ECBC)

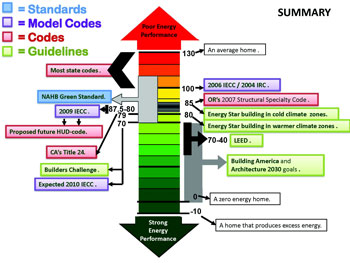

The Bureau of Energy Efficiency (BEE), Government of India, launched the ECBC-Energy Conservation Building Code-in 2007 for commercial buildings with peak demand in excess of 500 kW or connected load in excess of 600 kVA. Analysis done during the development of the ECBC shows energy savings in the range of 27%–40% in an ECBC-compliant building over a typical commercial building with an annual energy consumption of 200 kWh/m2.

The ECBC sets minimum energy performance standards for the design and construction of large commercial buildings. It encourages energy-efficient building systems, such as building envelope; lighting; HVAC (heating, ventilation and air conditioning); water heating; and electric power distribution, within the building facilities while enhancing thermal and visual comfort, and productivity of the occupants.

Compliance Approaches

ECBC compliance procedure requires the new building to fulfil a set of mandatory provisions related to energy use as well as show compliance with the specified requirements stipulated for the different building components and systems. These mandatory requirements are well described in ECBC and the code also specifies perspective requirements for building components and systems. However, to maintain flexibility for the design and construction team, the code compliance can be met by following one of the two methods.

Perspective Method -specifies prescribed minimum energy efficiency parameters for various components and systems of the proposed building. Perspective requirements like Building envelope, HVAC systems, Service hot water and pumping, lighting systems and electric power are dealt in detail in ECBC.

Whole Building Performance (WBP) Method -is an alternative method to comply with the code. This method is more complex than the Perspective method, but offers considerable flexibility in terms of design. It allows for code compliance to be achieved by optimising the energy usage in various building components and systems in order to find cost effective solutions. WBP method requires approved computer software to model a proposed design.

WBP method considers all building components during the design phase. It integrates all the sub-systems and parts of the building to work together. Because all the pieces must fit together, it is essential that the design team be fully integrated from the beginning of the process. The building design team can include architects, engineers, building occupants and owners, and specialists in areas such as indoor air quality, materials, and energy use.

WBP takes into consideration the building structure and systems as a whole, and examines how these systems work best together to save energy and reduce environmental impact. For example, a building that uses extensive day lighting techniques will reduce the amount of heat given off by lighting fixtures, thus allowing for a smaller air-conditioning system. This whole-building philosophy considers site, energy, materials, indoor air quality, acoustics, natural resources, and their interrelation.

This approach brings together building design, energy efficiency, and today's solar technologies to boost your energy savings and make the most of all your building's elements. It reduces the amount of energy required to operate a building compared to conventional buildings. It improves the comfort of building occupants by using aesthetically pleasing architectural designs to brighten up work areas using sunlight rather than electricity, without causing excess glare.

Benefits of WBP Method

"The Building Sector represents about 33% of electricity consumption in India, with commercial sector and residential sector accounting for 8% and 25% respectively. Estimates based on computer simulation models indicate that ECBC compliant buildings can use 40 to 60% less energy than conventional buildings. It is estimated that nationwide mandatory enforcement of ECBC will yield annual savings of approximately 1.7 billion kWh."- ECBC user Guide ref.

Indirect benefits of WBP include; reduced energy usage, reduced maintenance and capital costs, reduced environmental impact, increased occupant comfort and health, and increased employee productivity. Employee productivity and business profitability are linked. Recent studies have shown an increase in employee productivity when buildings are designed with occupants in mind—natural light, comfortable temperatures, and a quiet work environment being their most important issues. Research suggests that a well-designed workplace can increase employee productivity by 20%.

Design Guidelines (commercial building) 2

A high-performance commercial building design strategy requires a clear definition of goals and performance benchmarks from the owner, and an inter-disciplinary design and construction approach. Design criteria should be based on environmental and energy cost/benefit analyses and attention to whole-building and system performance

Pre-Design

Because all commercial building components must work together successfully long after project completion, it is essential that sufficient time be set aside in the beginning of a project for design team development, goal-setting, and project-planning. A sustainable building can only be accomplished when everyone (the building owner, future occupants, design team) have the same energy and environmental goals for the project from the start. In short, everyone who is affected by this building in a decision-making position should be involved at the project's beginning. Ultimately, the building owner is responsible for setting the goals and their implementation. It is the design team's responsibility to translate goals and budget for the project into measurable benchmarks for design, construction, and operations so the project will be successful.

Design

Traditionally, commercial building design choices are based on budget and/or time considerations. Single-building components are added or deleted to meet time or budget constraints without evaluating their impact on total building performance. Yet, basic design goals, such as minimizing energy consumption or maximizing daylight, cannot be done without understanding the impact of interrelations between the parts of the building, including window-glazing systems, the thermal envelope, mechanical system-integration, orientation, and floor-plate proportions. High-performance building design must ensure complete integration to achieve optimal building performance. These interrelations are very complex. As a result, computerized simulation studies are necessary to properly account for interrelationships. Water and resource conservation, along with recycled, reusable and non-toxic, sustainable materials should also be considered in the design stage.

Construction

Building construction is an act of creation than begins long before the first shovel pierces the ground. It begins with a statement of design intent, followed by creation of a performance program. Once these are approved, the process concludes with drawings and specifications, and then, finally, building commissioning during occupancy. Although simplified, below are some general guidelines:

Statement of Intent -a good statement of intent will clearly set forth the goals of the project, and current and possible future uses for the building, as well as a description of how building systems are to perform. Clearly defined goals and objectives here will help in the bidding process later on.

Performance Program - the performance program is the strategy for implementing the goals established by the statement of intent, such as budget, space planning, integrated building systems, and other specific needs. It will also set performance goals for systems, such as lighting wattage per square foot, and include such amendments as elimination of toxic materials. Several building rating systems exist that can be used to write the performance programs, such as the U.S. Green Building Council's Leadership in Energy and Environmental Design, or the LEED rating system.

Drawings and Specifications - these record the design intent. Most design firms use the format created by the Construction Specifiers Institute (CSI). However, keep in mind that for high-performance buildings, you will need to add "integrated systems drawings" and supporting documents that will illustrate how different building components relate to and impact each other. Specifications that accompany the drawings must clearly explain the design intent, especially if a project includes unusual or innovative practices or requirements.

Building Commissioning - this is the process of ensuring that building systems, such as air-handling equipment, security systems, and elevators, are designed, installed, functionally tested and capable of being operated and maintained according to the owner's operational needs. Commissioning begins in the design stage and extends at least one year into the initial occupancy of the building. This process ensures that the building is operating as designed. It also saves building owners money by keeping equipment and building systems compliant with warranties, prevents future excessive repairs, reconfiguration and replacement costs, employee absenteeism due to uncomfortable work environments with poor air quality, and frequent tenant turnover.

Strategies3

General Site Layout

-

Organize building mass, orientation and outdoor spaces to provide efficient access to services; incorporate recreational areas that have multiple functions in addition to visual value. For example, rooftops can be used as gardens and for water collection; a water feature in a playground can provide both cooling and recreation for children.

-

Use earth forms, plantings, drainage and water detention systems, and soils to support the functions of the building and site (e.g., screening, windbreaks, etc.).

-

Employ passive solar principles in architectural design, orientation, and sitting; use heat-retaining courtyard pavements (with proper shading), block winter wind and admit summer breezes.

-

Map sun and shade patterns associated with new construction. Design landscaping that optimizes selection and positioning of plants for sun and shade.

-

Incorporate adequate space for operational recycling and maintenance, including space for collection, storage, and access for collection vehicles.

Improved Environmental Quality

- Coordinate landscape design with building envelope design. Orient building, windows, and outdoor spaces to work together, taking advantage of light, air flows, and interesting views. For example, use plant materials to screen parking and service areas, or orient a conference room window toward a pleasant view. Design landscaping to be seen from and complement interior spaces. Capitalize on views into and out of the site and adjacent areas.

- Use deciduous shade trees and exterior structures such as louvers, arbors, and trellises to reduce cooling loads within the building.

Mitigation of Negative Impacts

- Reduce the urban heat island effect through tree planting and pavement selection strategies. In parking areas, use planting strips between sections of pavement to screen cars, reduce vast expanses of asphalt, and separate pedestrians from traffic and service areas. Consider planting trees and other vegetation along the perimeter or, if possible, within the parking area itself. Specify light colored paving with reflectance of at least 0.5; consider the use of porous pavement.

- Design to reduce potentially detrimental conditions, such as erodible slopes, slippery soils, high water table, and undue exposure to storms.

- Avoid adverse impacts on adjacent properties, such as reflected glare and light at night, shading of adjacent green space, noise, air pollution, waste heat, or creation of gusty winds at grade.

- Select light fixtures that reduce or eliminate the effects of light pollution on neighboring sites and the sky.

Site Lighting

- Use light colored or reflective edges along driveways or walks to reduce dependence on high-wattage electrical lighting at night. Use high-efficiency lights in exterior contexts such as up lighting fountains or sculptures, parking lights, and pedestrian lights.

- Use solar power for exterior lights, telephones, and fountain pumps whenever site conditions allow.

Interior Layout/Spatial Design

An appropriate layout of program spaces will help reduce energy consumption and will promote the use of passive solar heating and cooling.

-

Program zoning-Group similar program functions in order to concentrate similar heating/cooling demands and simplify HVAC zoning loads. Determine optimum locations within the building so as to take advantage of microclimate conditions and building orientation.

-

Non-windowed spaces as buffers-When using passive solar design for heating, non-windowed spaces should be located on the north side against the exterior wall to create a thermal buffer for the main functions on south side.

-

Circulation zones as buffers-Design public areas and circulation zones to serve as thermal collectors and buffers. These spaces can accept a wider range of temperature swings, based on limited duration of occupancy.

-

Layout for natural systems-Whenever possible, configure occupied spaces to optimize natural ventilation and day lighting. In general, locate open occupied spaces adjacent to exterior windows and use borrowed light for interior offices. Specify low partitions in office areas adjacent to window walls to enhance penetration of daylight to interior.

-

Existing natural systems- In an existing building, reuse and enhance existing built-in passive solar and energy efficiency strategies (EESs) such as natural convection, air circulation, building mass as a thermal flywheel, natural day lighting techniques, and other means.

-

Stairs-Provide inviting, pleasant staircases to encourage the use of stairs rather than elevators in low-rise buildings.

Indoor Air Quality

- Good indoor air quality encompasses such factors as maintenance of acceptable temperature and relative humidity, control of airborne contaminants, and distribution of adequate ventilation air. It requires deliberate care on the part of the entire project team. Achieving thermal comfort begins with good design and continues with proper building management, and seeks to avoid uneven temperatures, radiant heat gains or losses (e.g., from window areas), draftiness, stuffiness, excessive dryness, or high relative humidity (that can promote growth of mold and mildew).

- Through careful selection of materials, designers will avoid introducing potential pollutant sources. Mechanical engineers and allied trades people must select and install reliable ventilation systems that dilute the by-products of occupant activities and, to the greatest extent possible, supply fresh air on demand in the right quantities, in the right locations. During construction, air passageways need to be protected and mechanical systems must be balanced and commissioned to achieve optimal operation. Facility managers and maintenance staff also play a role in keeping areas clean while minimizing the use of irritating cleaning and maintenance supplies.

- Even if all objectives are met, attaining an indoor air quality that’s acceptable to all may be difficult to achieve, owing to the diversity of sources and contaminants in indoor air, as well as occupant perceptions and individual susceptibility.

Good Visual Quality

-

The daily rhythm of natural light sets our biological clock. Its seasonal rhythm influences our mood, and its presence is necessary for a number of health-sustaining biological processes. Since most of us spend more than ninety percent of our time indoors, buildings should provide as much day lighting to as many occupants as possible.

-

Day lighting, controlled by building openings, glazing types, and the configuration of reflecting surfaces, offers a rich spectrum that improves visual acuity. Its dynamic changes over the day provide visual stimulation, and keep us connected with the outside world. Electrical lighting systems should complement natural light.

Acoustic Quality

- A good acoustic environment keeps noise at levels that do not interfere with activities within programmed space. The primary acoustical and speech privacy requirements in offices include the ability to speak without having conversations overheard by co-workers, and freedom from distractions caused by nearby conversations or other intruding noises. Architecturally, there are three aspects to consider: sound isolation, building services noise and vibration control, and room acoustics. Sound and vibration isolation requirements for a given space will depend on desired ambient noise levels, the extent that external sources (e.g., normal traffic, fire/ambulance/police, car alarms, air traffic) impinge upon the space, and the level of noise and vibration from nearby sources and activities. Building services that may contribute excessive noise and vibration include HVAC systems (air handling units, variable air volume and fan-powered terminal units, ductwork, diffusers, registers, and grilles), plumbing (chillers, cooling towers, boilers, pumps, pipes, valves, restrooms, laundries, and other uses) and electrical systems (dimmers, lighting fixtures, transformers, and generators).

- Noise abatement begins with avoiding noise-generating factors, containing inevitable noise at the source, and locating sensitive spaces away from known noise sources. Sound-attenuating barriers and absorptive room surfaces must control noise transmission through the building structure and within rooms. To achieve positive acoustic quality in a room, spatial configuration and materials must be designed for appropriate resonance patterns. In overly quiet rooms, white noise can be used to mask private conversation.

Building Materials

Selecting materials for high-performance green buildings requires a balanced consideration of many factors. Project decision makers must weigh the long term performance and service of a material against such factors as first cost and environmental impact. Aesthetic appeal, maintenance and interior air quality concerns are also directly related to material selection. The project team must consider the environmental consequences associated with the acquisition, transportation and manufacturing of materials prior to construction.

It is important to look at material selection in a comprehensive manner at the beginning of a project. The following issues must be evaluated when choosing materials and building components for high-performance green building.

Integrate materials with building systems-High-performance green building design requires that materials, finishes and systems be considered as part of the overall integrated design. For example, the role of mass in building thermal and energy performance is well understood and may be modeled and predicted with available software. The strategic placement of massive materials within the building, therefore, has building space conditioning system performance implications and has attendant value as part of that system. The effectiveness of day lighting schemes is dependent on surface finishes and color selections in the spaces served by the daylight. Replacing a poor quality carpet in a space with an alternative surface treatment may eliminate a source of dust and volatile organic compounds while making the space healthier and more productive.

Choose products with the least toxic manufacturing process-The project team need to know how materials are obtained and manufactured to evaluate whether they are an environmentally responsible choice.

Specific products must be carefully scrutinized. For example, different types of rigid insulation use different foaming agents. Those that do not use chlorofluorocarbons (CFCs) or hydrochloro fluorocarbons (HCFCs) are the better choice. Similarly, carpets that are solution-dyed create fewer toxic byproducts. An electrostatic spraying process achieves a high quality, durable finish while allowing efficient reuse of over sprayed paint.

Manufacturers that use pre-consumer waste from their own processes have lower waste disposal costs and require fewer raw materials.

At the same time, decision makers should be wary of references to non-toxic or natural materials. Arsenic, asbestos and lead are found naturally in the environment. Natural materials must also be considered in reference to the same standards of performance, durability and serviceability as non-natural materials.

Choose products that are manufactured with the least energy intensive processes-The amount of energy used to extract raw materials and process them into a product is called the embodied energy of a material or product. Generally, materials that depend on extraction-based industries such as strip mining or clear cutting are not as desirable as those that are remanufactured using less environmentally damaging processes. Materials that are not highly processed or dependent on synthetics are preferable to those that rely on energy and resource intensive processes.

Specify sustainable products, preferably with recycled content-Recycled content can be pre-consumer using material gathered from the manufacturing process, or post-consumer materials gathered from general recycling efforts. Many manufacturers now list the percentage of recycled content in their products. In Pennsylvania, the Pennsylvania Resources Council is a great resource for information on products manufactured with recycled materials.

As with all materials, the inclusion of recycled content does not guarantee a sustainable product. Avoid specifying materials that can only be down cycled at the end of their useful life. For example, composite wood products, laminated trusses, structural insulated panels (SIPs), cellulose insulation and many other products with recycled content have become main stream. Specifying such materials can be done for reasons beyond the environment.

Consider reused building materials-When buildings are deconstructed rather that demolished, there are many materials that can be directly reused. The opportunity to reuse salvaged materials found on site begins with an assessment of what can reasonably be extracted from the building to be deconstructed. Inferior or overly damaged products often should not be reused for safety or other reasons. Code issues regarding lead, asbestos and other hazardous materials will prevent other materials from being reused.

A durable building material can cost more to purchase and install than a low first cost alternative, but will often pay for itself over time. A low first cost may hide the costs of repairs and eventual demolition, repurchase and reinstallation. This can be both expensive and inconvenient. In addition, there may be a long period of blight between the first signs of material wear and its ultimate replacement. More durable materials may be more pleasing to see and touch over the life of the building.

Material Characteristics

They benefit the building occupants and management immediately and over the life of the building. Examples include materials that:

-

Have low or no chemical emissions that can lead to poor indoor air quality

-

do not contain highly toxic compounds

-

are durable and have low maintenance requirements

They are resource efficient. Examples include materials that:

- Have recycled content (post-consumer and pre-consumer)

- are easily reused (whole or through disassembly)

- are easily recycled (preferably in closed-loop recycling systems)

They have far-reaching, global impacts. Examples include materials that:

- Contain no CFCs, HCFCs, or other ozone depleting substances

- are obtained from sustainable harvesting practices (such as certified wood products)

- are obtained from local resources and manufacturers

- have low embodied energy

- are derived from renewable resources

- are biodegradable when disposed.

Water Reuse

To achieve overall water conservation goals, it is important to limit the use of potable water for non-potable purposes. On-site water reclamation and reuse should be encouraged and facilitated wherever possible.

-

Rainwater use- Collect and use rainwater for landscape irrigation, urban gardening, toilet/urinal flushing, roof cooling (for un-insulated roofs), and for other purposes as appropriate.

-

Green roofs-Plant roof areas to reduce the discharge of storm water and to reap the benefits of increased green space (recreation, bird habitat, roof shading, etc.).

-

Gray water use-Collect and use gray water for water closets and urinal flushing, as well as for wash down of floor drains.

-

Excess groundwater-Recover excess groundwater from sump pumps for use as a source of recycled water.

-

‘Vacuum-assist’ systems- Consider a ‘vacuum-assist’ system (in lieu of a standard system) for flushing of water closets and urinals.

Health and Safety

Construction workers and building occupants need protection from pollutants produced during construction, such as volatile organic compounds (VOCs), particulates, dust and other airborne contaminants and odors. These same construction contaminants must also be prevented from accumulating in building HVAC systems and in absorbent building materials, such as carpet and furnishings.

Waste Management Plan

Stipulate a requirement in the contract documents requiring a Waste Management Plan by the contractors. The plan will include the measures listed below. Where referenced, existing guidelines or standards should be used to define the scope of a specific measure.

- List materials to be salvaged for reuse in the project in the contract documents.

- Identify local haulers for salvaged materials and products that will not be reused in the project. List all additional materials that are economically feasible for salvaging in the project.

- Identify licensed haulers of recyclables and document costs for recycling and frequency of pick-ups. Confirm with haulers what materials will and will not be accepted. List those materials that are economically feasible for recycling in the project.

- Identify manufacturers and reclaimers who recover construction/demolition scrap of their products for recycling. List all materials that are economically feasible for reclamation and any special handling requirements for each material. Examples include carpets, ceiling tiles, and gypsum wallboard.

- List procedures to be taken to comply with New York City recycling law. Recyclable materials include bulk metals, corrugated cardboard, bottles, and cans.

- Identify manufacturers who reclaim their packaging for reuse or recycling. Identify manufacturer and distributor options for reduced packaging, where available.

- Develop procedures for separating hazardous waste by-products of construction (examples include paints, solvents, oils and lubricants) and for disposing of these wastes according to appropriate federal, state, or local regulations.

Other Waste Prevention Measures

- Educate workers on waste prevention goals and the proper handling and storage of materials.

- Where applicable, re-use salvaged material at the site.

- Coordinate ordering and delivery of materials among all contractors and suppliers to ensure that the correct amount of each material is delivered and stored at the optimum time and place. This can help prevent material loss, theft, and damage.

Conclusion

The technologies that enable high performance buildings have advanced in recent years along with a sharper focus on total costs, energy efficiency and sustainability. Achieving the full potential of high performance buildings requires a whole building, whole lifecycle approach that recognizes opportunities to reduce total costs of a building’s occupied life, rather than focusing only on first costs.

The technologies that enable high performance buildings have advanced in recent years along with a sharper focus on total costs, energy efficiency and sustainability. Achieving the full potential of high performance buildings requires a whole building, whole lifecycle approach that recognizes opportunities to reduce total costs of a building’s occupied life, rather than focusing only on first costs.

High performance buildings are energy-efficient, durable, environmentally responsible and much more. They are organizational assets that improve the comfort, productivity and efficiency of the people and organizations that occupy them. Ultimately, a high performance building becomes a strategic asset that helps an organization achieve its primary mission and pays for itself many times during its occupied life.

Acknowledgements

This article has been an attempt to provide an overview of the field and readers may find some aspects not dealt at length. There is nothing of any original contribution by the compiler in this article, which is a merely a compilation and consolidation of information from many diverse sources, mainly with an intention to disseminate the required information among the fraternity. We express, with a deep sense of humility, our gratitude to those authors and information centres from where the information is collected.

References:

-

ECBC Training Module

-

High-Performance Buildings - InterNACHI

-

HPB Guidelines-Department of Design and Construction New York

-

Guidelines for Green Buildings

-

ECBC User Guide

-

High Performance Buildings- Michel van Roozendaal