CUNY building spreads out with new design

With its implausible history of education, John Jay College of Criminal Justice of the City University of New York (CUNY) has received an overwhelming response from the citizens of New York over past few decades. The college was established in 1964, to educate police officers in sciences and liberal arts.

| John Jay College of Criminal Justice is the preeminent national and international leader in education for justice. Recognised as one of the senior college, John Jay offers students a liberal arts and criminal justice curriculum that balances the sciences, humanities and the arts with professional studies both at undergraduate and graduate level. Here, the students learn how to transform their ideas into social action and leadership through rigorous course work, research, internships, community service, and other learning experiences. As a result of a |

|

John Jay education, students and graduates gain the skills and knowledge to become fierce advocates for justice in their communities, across the nation and throughout the world.

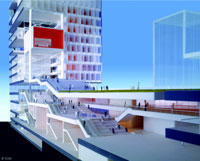

Keeping the demand for criminal justice education, the college management decided for the expansion of the College premises. The Expansion Project is a new 625,000-square foot academic building in Midtown Manhattan consisting of a 15-story tower on 11th Avenue and a four-story podium with a garden roof that connects to the College's existing Haaren Hall on 10th Avenue, effectively consolidating the campus into one city block. In response to a shallow train tunnel that cuts through a corner of the site, the John Jay structural system is distinguished by a grid of rooftop trusses which hang the perimeter of eight of the floors below and create a dramatic column-free cafeteria space on the 5th floor with clear views of the Hudson River for the full 195’ width of the building.

Built Expressions in an exclusive interview with Mr. Jason Stone, Project Manager - LERA shared his experience in providing structural services for the landmark project John Jay College of Criminal Justice.

Sharing his experience working on this commendable project Mr. Stone says, “John Jay College was a special project to work on for a number of reasons. The purpose for the project was inspiring – to increase capacity and provide state of the art facilities for New York City’s premiere college training students in criminal justice and law enforcement. After the tragedy of September 11th, 2001 this has never been more important for our city and country. And finally, the opportunity to solve a common urban problem – a train tunnel running beneath the project site – in an innovative way that provided structural efficiency, enhanced the architectural expression, and allowed the contractor to meet the design schedule.”

The design team was exceptional - led by the creative genius’s at Skidmore, Owings & Merrill and guided through construction by Turner Construction. Jaros Baum & Bolles, Langan Engineering, and Shen, Milsom & Wilke provided invaluable expertise and were committed to working together to meet the design goals. Owen Steel and Cornell & Company exceeded every expectation with the steel fabrication and erection.

|

Key Challenges

The primary construction challenge involved achieving approximately level floors opening day and a 2” stack joint in the curtain wall at the transition floor between the conventionally framed and hung structure. To simplify the steel frame erection, the design accounted for temporary columns at the 5th floor around the tower perimeter, and temporary angles bolted to the plate hangers above the 6th floor, to stiffen these elements during erection. This allowed the construction process to proceed similar to conventional construction and maintain the project schedule. Once the truss assembly was finished, jacks at the temporary columns slowly lowered the building and engaged the trusses. At this point, the temporary columns and angles could be removed.

Addling to this, Mr. Stone says, “Another challenge involved the main podium entrance on 59th street, which contains a 30’ grade change between 10th and 11th avenues. To design for this condition, the perimeter columns – in an area that supported heavy loads from the rooftop garden – were eliminated, and the entrance was pulled back to allow room for the steps and ramps. Story-deep trusses were fit inside the walls of the 4th floor classrooms to efficiently accomplish the 40’ cantilever out to the tip of a V-shaped tapering canopy. A series of cascading staircases and escalators allow for fluid circulation to all parts of the campus.”

Steelwork

Calculating the required amount of vertical cambering of the steelwork was a challenge. Design estimates were based on the assumed construction schedule, estimated construction loads and realistic modelling of the structural behaviour. Mr. Stone says, “During construction, continuous surveying verified the perimeter’s behaviour as we anticipated. Once we had shop drawings for the non-structural elements, and a more accurate schedule, we did a full re-analysis incorporating what we were learning from the surveying. During this re-analysis, we determined that the perimeter would likely not come down as much as we originally thought; one reason being the curtain wall was 30% lighter than assumed and field adjustments were made to lower the steel frame prior to starting the truss erection. This adjustment proved wise as the last survey data received showed the building followed our predictions closely and the final stack joint met the intended thickness.”

Measure to Prevent Train Noise & Vibration

To effectively isolate the building from the train vibration and noise, two layers of structure were provided. The train tunnel was enclosed with a hollow core precast plank ceiling and concrete crash walls and the main building structure spanned over and behind these elements. At points of convergence, creative detailing was required to maintain the load path and necessary separation.

Accommodating the necessary two layers of structure around the train tunnel mandated a practical limit to the weight that could be supported. Exploring numerous options, the hanging solution was favoured by SOM and DASNY and adopted for numerous reasons, including assistance in achieving the series of distinguishing setbacks that frame the west facade’s main entrance along 11th Avenue. Thin plate hangers were installed inside standard partition walls – instead of traditional column enclosures – to hang the full perimeter, balance the weight, and complete the column-free aesthetic. To maintain efficiency, the hanging system was stopped where the structure over the tunnel could accommodate conventionally-framed floor weight. In coordination with the architect, the 5th floor was chosen for this transition, allowing the column-free floor to align with the podium roof garden.

|

|

Design for Future Expansion

|

Elaborating the idea of the future expansion of the College Mr. Stone says, “After quick discussions, it was agreed with the College to only reinforce the foundations up to the slab-on-ground and take advantage of a hanging structural system similar to the one used in the tower to reduce the affected area to the interior core and limit the financial and schedule impacts as much as possible. Additional elevator pits with knock-out slabs were provided along with significantly reinforced foundations based on the anticipated future circulation and structural weight needs. Instead of increasing the column and vertical bracing

|

|

member sizes for the expected future loads, the additional capacity is intended to come from a high strength composite concrete encasement allowing the already fabricated vertical members to still be used.”

Good Design Matters

For Mr. Stone, it was the good design principles which mattered the most than the cutting edge technology to keep the construction costs down. He says, “Labour is expensive in New York City. So, every effort was made to maximize the amount of work that could be done in the fabrication shop and limit the field work. Accordingly, all the truss connections and splices were bolted instead of welded. Careful thought was given to the frame erection considering the hanging structure. Temporary columns at the 5th floor and temporary angles on the hangers allowed the frame erection to proceed without any special requirements and maintain the construction schedule.”

Innovative Materials

According to Mr. Stone, in the project, the structural system was innovative, but the structural materials were traditional. Structural steel was the natural chose for the building material given the site constraints and design intent. It created a lighter building which helped reduce loads on the foundations and made possible the many long-span and cantilever conditions required.

He explains, “Neoprene bearing pads and special foam isolation pads provided vibration and acoustic separation between the tunnel and building. Rectangular steel plates were chosen as the shape for the tower perimeter hangers so, they would be narrow enough to fit in a standard gypsum partition wall. These and the column free perimeter for the 5th floor maximized views of the Hudson River and podium garden roof. Fly ash and silica fume was used as a replacement for some of the cement to be sensitive to the environment.”

Environmental Suitability

While the building did not officially submit to USGBC, the project specifications were written to match up with LEED certification requirements. Structurally, this meant taking advantage of fly ash and silica fume to replace up to 30% of the cement in the concrete. The reinforcing and structural steel were sourced from a mill regionally close to NYC and produced from over 90% recycled content.

Green Roof

The 65,000-square-foot roof terrace serves as a new, outdoor gathering place for students and faculty. The planted green roof is landscaped with large grassy zones, full-sized trees, and decked outdoor dining areas.

The green roof of the building is well planned and executed well. Explaining about the concept of green roof design Mr. Stone says, “The podium garden roof was the work of the College and SOM. The podium serves as a link building between the College’s existing Haaren Hall on 10th Avenue and our new tower on 11th Avenue. Turning the roof into a garden allowed another main circulation artery for flow between the towers. Also, it was an opportunity to provide the rare and special gift of an elevated green oasis in the midst of the urban concrete jungle for their students and faculty. The tree plantings were chosen to shield wind from the Hudson River and provide some cover from the neighbouring buildings. The soil depths were carefully coordinated with the needs of the various types of plantings to limit the additional weight on the structure.”

|

JASON B. STONE, P.E.

Senior Associate

As Project Manager, Mr. Stone provides detailed guidance to the analysis and the development of the structural design and coordinates the structural engineering services with Owner, Architect, Services Engineer and Contractor. He works closely with LERA’s Project Director and Partner-in-Charge and with the staff of other firms.

Project Facts

Project Completion Year: 2011

Design Completion Year: 2006

|

|

Site Area: 100,000 ft2

Project Area: 625,000 ft2

Number of Stories: 14

Building Height: 240 ft

Project Awards

2013: AIA - New York City Chapter, Design Award

2013: Society for College and University Planning (SCUP), Excellence in Architecture

2012: AIA - New York City Chapter, Design Award

2012: AIA - New York State, Award of Merit

2012: Architect Magazine, Annual Design Review

2012: Engineering News Record, Award of Merit, Best of

2005: AIA - New York City Chapter, Design Award: Project