Potential Housing Technologies Identified by BMTPC for Social Mass Housing in India

Dr. Shailesh Kr. Agrawal, Executive Director

& J. K. Prasad, S. K. Gupta, and Dalip Kumar

Building Materials & Technology Promotion Council, Ministry of Housing & Urban Poverty Alleviation, Government of India, New Delhi.

INTRODUCTION

With annual growth rate of 2.7%, urban population in India rose to 286.1 million as per 2001 Census and more than 377 million constituting 31.16% of the total population as per 2011 Census of Government of India. It is projected that urban population will continue to grow and reach 470 million in 2021 and 700 million in 2041. With current pace of urbanization, our cities are facing major shortage of housing stock and also despite of best efforts by the Government, the gap between available housing stock and required is ever increasing. A Technical Committee constituted by Ministry of Housing & Urban Poverty Alleviation to assess housing shortage at the beginning of the 12th Plan, has estimated the shortage at 18.78 million in 2012. Against this, about 18 million of shortage is estimated to pertain to EWS and LIG categories. Out of the total shortage of 18.78 million, 14.99 million is on account of congestion factor, i.e. 14.99 million households live in congested houses requiring home improvement or new houses. The recommendation of the Technical Committee is that both housing improvement and new housing be included while addressing the housing shortage in the country. Housing and habitat related services for the urban poor and low income groups are estimated to cost a sum of about Rs.6,00,000 crores which requires proper planning, policy frame work and technical interventions to deal with the subject.

Realizing the challenge, the Government of India took several initiatives to create opportunities and supporting environment to overcome this housing shortage in most effective manner. The National Urban Housing and Habitat policy 2007 by the Ministry of Housing and Urban Poverty Alleviation, inter-alia, lays emphasis on using technology for modernizing the housing sector for enhancing energy and cost efficiency, productivity and quality specially to meet the housing needs of the poor. It encourages use of prefabricated factory made building components so as to achieve speedy, cost effective and better quality construction. Through ongoing Jawaharlal Nehru Urban Renewal Mission (JNNURM, Government of India’s Scheme for slum renewal), and newly launched Rajiv Awas Yojna (RAY, Government of India’s new scheme for slum renewal & slum prevention), the central Government gives State Governments the opportunity to eradicate slum and create necessary housing stock and basic services to the poor. This gigantic task needs a review of our construction practices and study of emerging technologies so as to introduce best technologies and practices suiting our conditions for construction of housing stock in different parts of the country.

BMTPC has been promoting cost-effective, environment-friendly, energy-efficient and disaster resistant technologies developed in India. With fast depleting natural resources; need for environment protection to protect greenhouse effect; need for bringing more speed, durability and quality in construction; it is prudent to widen the horizon to look for alternate cost effective technologies within and outside the country. BMTPC took an initiative to study/select emerging and alternate cost effective technologies suitable to Indian geo-climatic conditions and advocate these technologies to the State Govt. so as to initiate pilot projects in different parts of the country.

BMTPC's INITIATIVE

BMTPC has been identifying & evaluating suitable technologies for mass housing, as a cost effective substitute for conventional system. Based on the information with respect to material and structural details, status of evaluation, actual construction carried out in India or elsewhere and their performance, economic scale of construction, status of transfer of the technology to India, suitability for mass construction in urban areas, durability & speed of construction, cost effectiveness, innovation in technology, ease of working & adaptability in Indian condition, etc., the following broad parameters were considered for evaluation of technology/system:

- Structural stability

- Material specification and its durability

- Green concept

- Joints and connections specially for prefabricated system

- Cost effectiveness of the emerging technologies vis-à-vis conventional construction system (RCC and masonry construction)

- Speed of construction and quality

- Sanitation

- Suitability to Indian climatic and hazard conditions

- Scale of minimum number of houses

- Adoptability of Services.

- Expected life span of the proposed system

- Maintenance scheme for the system

- Resistance of the system against fire, blast, etc.

- Users’ feedback and certification, wherever possible.

- Compatibility and adherence of the system to BIS

- Any shortcoming of the system

Based on the broad parameters, the short listed technologies/systems are :

INTRODUCED TECHNOLOGY/SYSTEM

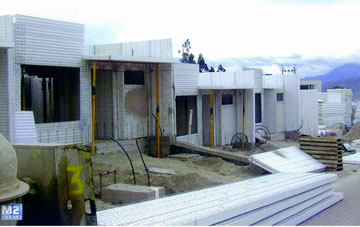

1. Panel building system using steel mesh, polystyrene core and chipping concrete

|

The panel Building system is a load bearing wall construction which is seismic resistant and thermally insulated. It is reported that buildings of any typology or architectural structure, ranging from most simple to the most complex one, could be constructed. The base element of the building system is a modular panel composed of two electro- welded galvanized steel meshes, reciprocally joined by connectors, in the middle of which is a suitably shaped foam polystyrene plate. High resistance steel meshes composed of bars having dia. 2.5 to 5 mm. are made in factory. Panels could be supplied with meshes having different dia. and different geometrical characteristics. Polystyrene is self- extinguishing foam polystyrene suitably shaped, used both as a disposable form and as an insulating layer. The EPS is made of carbon, hydrogen and for 98% air. Thickness, shape and density of the polystyrene core may change according to specific requirements. The minimum density normally used is equal to 15 kg / m3.

|

Once the panels are installed, they are anchored and finished with the application of light concrete on both of their sides. Thus, buildings with load bearing walls consisting of two reinforced concrete plates are made integral by a thick network of connectors, with an insulating core. Single panel is finished, by applying on each a layer of chipping concrete having characteristic resistance of 30 Mpa at least. As load bearing element, the double panel and the floors are finished during the installation with concrete of suitable grade placed into the slab ribs as well. Should the panels carry out a non-load bearing function , a concrete plaster , even a pre mixed one , is applied for a thickness of at least 25 mm.

2.Technology using expanded steel mesh panels, polystyrene beads & alleviated concrete

|

The system is entirely a "on-site" construction process, not based on prefabricated, pre cast or preassembled elements and is a most spectacular, versatile and efficient construction system. The houses are entirely, including the roof, made up of structure panels assembled with Beams. |

Alleviated concrete, a special mix of concrete and expanded polystyrene beads, hence incorporating both the thermal and the sound insulation, is injected into a steel structure made of panels reinforced with beams (galvanized steel wire studs / steel rods).

|

The Concrete base and the foundations of the houses are prepared in a conventional manner. They can be made from regular, poured, heavy concrete, but more generally the use of alleviated concrete or at least of one more layer of alleviated concrete, will provide good thermal insulation and good comfort from the ground also. |

Prior to the pouring of the concrete of the base, the panels are tied to the soldered wire mesh and to the iron rods in the base and in the foundations and assembled in accordance with the design of the house. They are then, held together by special made galvanized steel wire studs, which fit one into the other, horizontally and vertically, to form the complete skeleton of the construction, roof included.

|

The assembled panels form a rigid, extremely robust, self-supporting steel skeleton, comprising the outside walls and all other bearing walls and partitions, the floors and ceilings, including the roof. Doors and walls are then simply "cut out", using steel scissors or other steel cutters. Cut-offs is recovered and re-used. |

Templates of doors and windows are positioned. Instead of using framework, both sides of each panels are then simply covered with a galvanized wire mesh/fencing mesh/Chicken mesh, which is clipped to the panels, and will serve as a frame when the alleviated concrete injected.

"Alleviated" or "light" concrete is then injected with a special concrete pump. This pump can operate from a distance of 60 meters and to a height of up to 60 meters (almost 20 floors). The alleviated concrete is a custom-made mixture of cement, fiber, sand and Expanded Polystyrene (EPS) beads (1 to 4 mm), resulting in a low-density concrete (50-700 kg/m3) and hence incorporating thermal and sound insulation. The injected walls are then finished / leveled / smoothened from both sides. The concrete-injected then forms a true and quasi-homogeneous composite with incomparably better properties than plain steel reinforced concrete; Offers excellent thermal and phonic insulation; has walls that breathe; is completely resistant to fire; Offer complete protection against earthquakes and hurricanes and; is immune to termites and other insects.

3. Pre-stressed precast prefab technology using hollow core slab, beams, columns, solid walls, stairs, etc.

|

Pre-stressed precast RCC technology using hollow core slabs, beams, columns, solid walls, stairs etc. are designed and manufactured in factory, shipped and erected at site. Multi-storey precast concrete frames are constructed with columns and beams of different shapes and sizes, stair and elevator shafts and floor slabs. The joints between the floors elements are executed in such a way that concentrated loads are distributed over the whole floor. This system is widely used for multi storey buildings. The structural frame is commonly composed of rectangular columns of one or more storeys height. The beams are normally rectangular, L-shaped or inverted T-beams. They are single span or cantilever beams, simply supported and pin- connected to the columns. Hollow core floor slabs are by far the most common type of floor slabs in this type of structure. |

4. Monolithic concrete technology using plastic / aluminium composite formwork

|

In the monolithic concrete technology, Walls and slabs are cast in one operation in specially designed light weight form/ moulds in concrete. Concrete is poured in the forms & forms are removed after the setting of concrete takes place, resulting in box like cubical structure of required architectural design. The pre-designed formwork also acts some sort of assembly line production and enables rapid construction of multiple units of repetitive type. |

5. Monolithic concrete construction using aluminium formwork

|

In the Monolithic concrete construction with aluminium forms system, Concrete walls and slabs are cast monolithically at one pour. The system allows reduction in thickness of concrete members below the minimum value than the conventional construction, thus reducing the consumption of natural resources. Single floor with built up area of about 300 sqm. can be completed in two days using the aluminium formwork system. The technology reduces the cost of repair and maintenance compared to conventional system. |

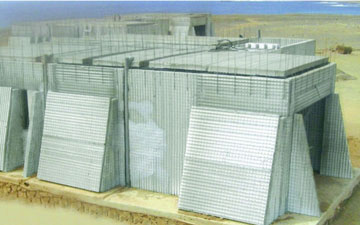

6. Precast concrete panels using concrete, welded mesh and plates, polystyrene core

|

|

Pre-cast concrete load bearing panels are made of reinforced concrete with a polystyrene insulated core that varies in size from 40mm to 200mm depending upon the insulation requirements. The reinforced concrete panels are moulded in specially designed steel moulds under controlled factory conditions. Then the panels are removed from the moulds and stacked vertically for curing. Power and water conduits are installed in the panels during production. The buildings and houses can be designed to suit any geographical position or environment and can withstand wind speed in excess of 285km/hr. The system does not impose any design restrictions and can be used for any kind of architectural and aesthetic design as these panels are custom designed and manufactured. The panels have smooth surfaces. However, any kind of texture can be added on to the panel surface. Due to cohesive structural design, the system requires only strip foundation for most buildings. Concrete panels can be designed with strength of 5000 psi. These results in stronger panels than concrete blocks or most poured concrete walls but are thinner and light weight. The panels are of good quality and uniformity as they are cast and cured in controlled factory environment. The panels can be installed in fraction of time. The foundation takes two hours to prepare and the panels are set in three hours.

7. Industrialized 3-s system using cellular light weight concrete slabs & precast columns

|

The industrialized total open prefab construction technology is based on factory mass manufactured structural prefab components conforming to norms of IS standards and BIS Certification mark. In this system Dense Concrete hollow column shell of appropriate size are used in combination with pre - cast dense concrete rectangular T Shape/L shape beams and lightweight reinforced autoclaved cellular concrete slabs for floors and roofs. |

The hollow columns are grouted with appropriate grade of in–situ concrete. All the connections and jointing of various structures are accomplished through in situ concreting along with secured embedded reinforcement of appropriate size ,length and configuration to ensure monolithic continuous resilient ductile behavior.

8. GFRG/ Rapid wall Building System technology

|

Glass Fibre Reinforced Gypsum (GFRG)/ Rapid wall is a building panel product, made essentially of gypsum plaster, reinforced with glass fibres. This product, suitable for rapid mass- scale buildings construction, was originally developed and used since 1990 in Australia. GFRG is of particular relevance to India, where there is a tremendous need for cost-effective mass-scale affordable housing, and where gypsum is abundantly available as an industrial by-product waste. The product is not only eco-friendly or green, but also resistant to water and fire. GFRG panels are presently manufactured to a thickness of 124 mm under carefully controlled conditions to a length of 12 m and a height of 3 m. The panel can be cut to required size. Although its main application is in the construction of walls, it can also be used in floor and roof slabs in combination with reinforced concrete. |

The panel contains cavities that may be filled with concrete and reinforced with steel bars to impart additional strength and provide ductility. The panels may be unfilled, partially filled or fully filled with reinforced concrete as per the structural requirement. Experimental studies and research have shown that GFRG panels, suitably filled with plain reinforced concrete, possess substantial strength to act not only as load-bearing elements, but also as shear walls,capable of resisting lateral loads due to earthquake and wind. It is possible to design such buildings up to ten storeys in low seismic zones (and to lesser height in high seismic zones). However, such construction needs to be properly designed by a qualified structural engineer. Manufacture of GFRG panels with increased thickness (150 mm, 200 mm) with suitable flange thickness can facilitate construction of taller building.

GFRG panels can also be used advantageously as infills (non-load bearing) in combination with RCC framed columns and beams (conventional framed construction of multi-storey buildings) without any restriction on the number of storeys. Also, GFRG panels with embedded micro-beams and RCC screed (acting as T-beams) can be used as floor/roof slabs.

GFRG panels can be unfilled when used as partition walls, but when used as external walls, need to be suitably designed (with reinforced concrete filling) in order to resist the design wind pressures. For single-storey construction (suitable for mass low-cost housing), unfilled GFRG panels can be used for walls as well as roof (which may be pitched suitably), with local reinforced concrete filling at the joints between walls and between the roof and walls. It is mandatory to provide embedded RCC horizontal tie beam over all the walls below the floor slab/roof slab.

9. Factory Made Fast Track Modular Building System using Concrete, Steel Structure and Polystyrene Core

Factory Made Fast Track Modular Building construction is a fast building solution manufactured and fabricated in a controlled factory environment and shipped to a prepared building site for installation. The system based on steel structure with different walling components is designed according to relevant Indian / International standards to withstand various forces. About 70% of the work is done in the factory with minimal usage of concrete which enables it to deliver the building within a few days of work at site.

The steel-modules pre-fitted with flooring, ceiling tiles, electrical and plumbing fittings are transported to the site for installation. Once all the components are assembled and erected at site, concreting is done on the factory made 3 -D Expanded Polystyrene (EPS) panel walls making it a monolithic structure.

The buildings and houses can be designed to suit any geographical position or environment and can withstand wind speed in excess of 285km/hr. The system does not impose any design restrictions and can be used for any kind of architectural and aesthetic design as these panels are custom designed and manufactured. The panels have smooth surfaces. However, any kind of texture can be added on to the panel surface. Due to cohesive structural design, the system requires only strip foundation for most buildings.

10. Light Gauge Steel Framed Structure Using Cold Formed Steel Sections

Light Gauge Steel Framed Structure is based on factory made galvanized light gauge steel components produced by the cold forming method assembled as panels at site forming structural steel framework of a building of varying sizes of wall and floor. The basic building elements of light gauge steel framing are cold formed sections which can be prefabricated on site using various methods of construction. Cold formed sections are widely used in construction including residential floors, industrial and commercial buildings, hotels and are gaining greater acceptance in the residential sector. Light Gauge Steel Framed Structure is already well established in North America, Australia and Japan and is gaining ground in India. Light Gauge Steel Framed Structure is typically ideal for one to three storey high buildings, especially in residential homes, apartments and commercial buildings.

Light Gauge Steel Framed Structure can be combined with composite steel/concrete deck resting on light steel framing stud walls. Apart from having potential for mass housing, modular buildings can be used for long term temporary or permanent structures such as schools, military and civil housing needs, post disaster relief structures and industrial buildings.

Construction phases of steel buildings resemble the phases of conventional reinforced concrete buildings. The building is designed and details of sections are worked out. Then the steel frame construction starts. The production takes place in the factory as floor, wall and roof etc. components of the building are manufactured as galvanized steel profiles in appropriate sizes. These profiles are sent to the construction site without loss, either as profiles or as panelized parts, considering the distance of the construction site and transportation conditions. Profiles are assembled by expert assembling teams at the construction site in line with the architectural plan. Only special studs are used during the assembly, no welding is done. When the assembly is done, the frame is filled with insulation materials (fiberglass, rock wool etc.). Walls are covered with standard boards or similar materials.The panels are assembled on site with screws and bolts to form the internal and separating walls and inner leaf of the external walls of a building and floors & ceiling. The building is completed by the installation of an external layer of insulation material and outer leaf of CP Board or dry mix shotcrete.The system can incorporate all types of architectural features like coving, boxes, cantilevers, projections, infill walls, mezzanine floors etc. This system can also incorporate all types of services viz. electrical, gas and plumbing etc. The design and engineering of the structures is executed by following the norms & guidelines stipulated in relevant Indian Standards.

11. Speed Floor

Speed floor is a suspended concrete flooring system using a roll formed steel joist as an integral part of the final concrete and steel composite floor. The Speed Floor system essentially is a hybrid concrete/steel tee-beam in one direction and an integrated continuous one - way slab in other direction. The joists of different depths are manufactured from pre - galvanized high tensile steel in a one pass roll

former, where it is roll formed, punched, pressed and slotted in a fully computerized machine manufactured in New Zealand. The joist depth and the concrete thickness are varied depending on the span, imposed loads and other functional considerations. The Speed Floor composite floor system is suitable for use in all types of construction. The Speed Floor joists are custom manufactured to suit particular job conditions.

The joists are manufactured from pre-galvanized high tensile steel in a one pass roll reformer, where it is roll formed, punched, pressed and slotted at a fast production rate. The ends are bolted to the joists which are then ready for shipping to site. The individually marked joists are placed on the support medium where the Speedfloor shuttering system locks the joist into the exact position. The Speedfloor joist’s modular spacing can be adjusted to suit varying conditions.

ROAD AHEAD

Now, it is required to see their application in the field for which demonstration construction should be the first priority. This alone would instill confidence in the mind of users and will also give an opportunity to examine the finer points, if any, of the construction. Some of the technologies identified, however, require setting up of manufacturing units and transfer of technologies. Such types of technologies need a big market for sustainability. It would also be necessary to develop specification, code of practice based on Indian conditions and analysis of rates. Since these technologies are unique in themselves, suitable methodologies would be required to be developed for their selection by government agencies in their projects. It is hoped that identification of such technologies which help in reducing time, enhancing quality, bringing in durability, sustainability would not only provide strong base to the construction industry which is already grappling with economic slowdown but also help in tiding over the huge housing shortage, currently exists in social mass housing sector.