Roller Compacted Concrete- RCC

And a Case Study- Ghatghar Dam Project

Bharathi Ganesh, Dr. H. Sharada Bai

Concrete is an important construction material since Roman times [the Colosseum

is largely built of concrete and the concrete dome of the Roman Pantheon is the

world's largest non-reinforced concrete Dome structure). Its appeal has endured

for a number of reasons, not least its compressive strength and resilience to weather

and fire but to its adaptability in creating a structure sound in every respect,

changing the design and construction world completely.

Recent innovations in concrete have further improved concrete’s credentials

in terms of its material consumption, overall cost per unit volume, duration of

construction required, performance, aestheticism, applicability, adaptability to

the site requirements, environmental friendly, sustainability [with the use

of industrial waste as alternative constituent in it], and so on. Many

new technologies are changing the way we build and what we build with concrete.

These developments in concrete have taken the construction industry by storm.

With the explosive growth in the infrastructure industry, another development in

1970 that has led to more creative use of concrete suiting to the requirements of

the site, to make the construction faster, is Roller Compacted Concrete [‘RCC’

for this article].

Definition

|

Definition - ACI 207.5R-89 defines Roller Compacted Concrete (RCC) as concrete compacted

by roller compaction. The concrete mixture in its unhardened state must support

a roller while being compacted [using a roller, often a vibrating roller].Thus RCC

differs from conventional concrete principally in its consistency requirement. For

effective consolidation, the concrete mixture must be dry enough to prevent sinking

of the vibratory roller equipment but wet enough to

|

|

permit adequate distribution

of the binder mortar in concrete during the mixing and vibratory compaction

operations.

The Genesis

Roller Compacted Concrete (RCC) got its start in the Seventies [1970], when the

Canadian logging industry switched to environmentally cleaner, land-based log-sorting

methods. The industry needed a strong pavement to stand up to massive loads and

specialized equipment. Yet economy was equally important: log-sorting yards that

can span 40 acres (16 hectares) or more. Roller Compacted Concrete met these challenges

and has since expanded to other heavy - duty applications.

Applications

Applications of Roller Compacted Concrete on other types of construction were developed

in the 1980s. Its primary use to date has been in new dam construction and

the rehabilitation of existing dams. It has also been used for paving areas that

receive heavy axle loads and has had limited use in road construction. Following

are some of the structures constructed using Roller Compacted Concrete (RCC)

-

In 1986, Gears, Inc. was the contractor on one of the first RCC dam rehabilitations.

-

Spring Creek Dam was the highest dam in the world to be rehabilitated using this

economically attractive and environmentally pleasing solution. It was nominated

for the Civil Engineering project of the year.

- New Application used along the Interstate-285 [an

Interstate Highway loop encircling

Atlanta, Georgia, for 63.98 miles or 102.97 km] shoulder

repaving project is doing more than reconstructing the roadway's shoulders with

6 inches of RCC, making a history.

- North of I-20, 16-in.-thick sections of existing pavement are

being removed and replaced with 8 in. of graded aggregate topped with 8 in. of RCC,

anticipating possible future use of the shoulder as a traffic lane.

- The Tennessee Valley Authority used 8,000 cu. yards of RCC as

structural fill to support the turbine-building slab at the Bellefonte Nuclear Power

Plant in Scottsboro, Ala.

- In 1980, the Ocoee No. 2 Dam in Ocoee, Tenn., was the first use

of RCC for overtopping protection.

- In 2001, Honda chose RCC for more than 100 acres of pavement for

its new car-manufacturing plant in Lincoln, Ala.

-

The Southeast Cement Association has recently been pitching RCC as a product that

is appropriate for smaller projects. Industrial park roads, small-scale site paving

and residential projects can all be candidates for RCC.

|

|

The facility General Motors' Saturn manufacturing plant in

Spring Hill, Tenn, built by Georgia Dept. of Transportation [GDOT] is the largest

RCC pavement project ever built, encompassing 134 acres of plant roads, vehicle

storage yards and delivery areas.

Performance

Roller Compacted Concrete may be used in lieu of conventionally

placed concrete in concrete gravity and arch-gravity dams. RCC can be placed as

quickly as possible and its operations include as little manpower as possible.

RCC structures have been designed for a wide range of performance conditions, from

low-strength more massive structures to high-strength less massive structures.

RCC has started its specialized applications in mainstream pavements such as Port,

intermodal, and military facilities; parking, storage, and staging areas, streets,

intersections, and low-speed roads. Now, RCC is used for any type of industrial

or heavy-duty pavement. The reason is that it has the strength and performance of

conventional concrete with the economy and simplicity of asphalt. Coupled with long

service life and minimal maintenance, RCC's low initial cost adds up to economy

and value.

The main characteristics like high strength, long-term durability and cost-effectiveness

make RCC simple, fast, and economical. Roller Compacted Concrete

pavements eliminate common and costly problems traditionally associated with asphalt

pavements.

RCC pavements

Roller Compacted Concrete pavements generally exhibit following characteristics;

- Resist rutting

- Span soft localized sub-grades

- Will not deform under heavy, concentrated loads

- Do not deteriorate from spills of fuels and hydraulic fluids

- Will not soften under high temperatures.

- When appearance is important, joints can be saw cut into the RCC

to control crack location. If economy outweighs appearance, the RCC is allowed to

crack naturally.

- The strength to withstand heavy and specialized loads; the durability

to resist freeze-thaw damage; and the versatility to take on a wide variety of paving

applications from container ports to parking lots makes RCC the right choice for

tough duty.

The main features of RCC with its benefits are summarized in Table 1

Cost Reduction

The reduction in overall cost of the project and hence reduction in the construction

times is due to the following points.

- Cement consumption is lower because much leaner concrete mixtures

can be used.

- Formwork costs are lower because of the layer placement method.

- Pipe cooling is unnecessary because of the low temperature rise.

[Use of Fly Ash].

- Cost of transporting, placement, and compaction of concrete is

lower because concrete can be hauled by end dump trucks; spread by bulldozers and

compacted by vibratory rollers.

Rapid construction techniques (compared with those for concrete and embankment dams),

reduced material quantities, very high production rates possible in construction

reduce administration costs directly. It also helps in achieving earlier project

benefits, possible reduction or deletion of diversion facilities and possible use

of dam sites with limited construction seasons.

The shorter base dimension of an RCC dam, compared with that of an embankment dam,

reduces the required size and length of the conduit and penstock for outlet and

hydropower works and also reduces foundation preparation costs.

An embankment dam with a separate spillway and outlet works is generally more costly

than the RCC dam with an integral spillway and outlet works. The cost of an RCC

dam intake is considerably lower than the cost of an intake structure for an embankment

dam, especially in high seismic areas.

Table 1 – Features and Benefits of RCC

|

Features

|

Benefits

|

|

High compressive strength (4,000 to 10,000 psi) (28 MPa to

69 MPa)

|

Withstands high concentrated loads and impacts from heavy industrial, military,

and mining applications.

|

|

High flexural strength

(500 to 1000 psi) (3.5 MPa to 7.0 MPa)

|

Supports heavy, repetitive loads without failure and spans localized soft

subgrade areas, which reduces maintenance costs and down time.

|

|

Modulus of Elasticity

|

6.9 GPa at one day, [21 – 38] GPa at 28days and [30-47]GPa at one year.

|

|

Poisson’s Ratio

|

Typically ranges from 0.15 – 0.22

|

|

High Shear Strength

|

Eliminates rutting and subsequent repairs.

|

|

High Density, Low Absorption

|

Provides excellent durability, even under freeze-thaw conditions; eliminates

seepage through pavement. Density ranges from [2240-2560] kg/m3.

|

|

Low Water Content,Low water/cement Ratio

|

Increases strength, reduces permeability, and enhances durability and resistance

to chemical attack.

|

|

Very Good Aggregate interlock

|

Provides high shear resistance at joints and uncontrolled cracks to prevent

vertical displacement or faulting.

|

|

No steel reinforcing or dowels except under special circumstances

|

Speeds and simplifies construction, reduces costs.

|

|

No forms or finishing

|

Speeds construction, reduces cost, minimizes labour.

|

|

No formed or sawed joints

|

Speeds construction, reduces cost. (To enhance appearance, joints can be sawn into

RCC pavement.)

|

|

Hard, durable, light-coloured surface

|

Resists abrasion, eliminates need for surface course and reduces cost. The light

color reduces lighting requirements for parking and storage areas.

|

Limitations

Some of the limitations of RCC constructions are;

- Aesthetics - RCC does not have the

same appearance as other types of concrete. It is not as pretty and smooth as regular

concrete.

- Rougher Surface Texture - The mix

design and construction methods create a surface texture that gives it a characteristic

coarse finish.

- Limited to Low-Speed Traffic - Due

to the nature of its surface, RCC is not appropriate for all types of traffic. Vehicles

travelling at high speeds would experience a little bumpy ride. That makes it better

for applications where strength and durability are needed instead of speed. This

part of RCC technology is being addressed with newer technologies and pavement topping

techniques to provide smooth surface of the roads.

Material Requirement

Material selected for RCC and designed mix should be such that

RCC must maintain a consistency that will support and be suitable for a vibratory

roller and haul vehicles or other external methods. Much of the guidance on materials

provided in ACI 207.1R (Mass Concrete) may be applied to RCC.

Cement & Cementitious Material

|

Cement & Cementitious Material

Roller Compacted Concrete (RCC), can be made

with any of the basic types of Portland Cement. The cementitious material content

for RCC dams has varied over a broad range from 100 lb/yd3 (59 kg/m3)

to more than 500 lb/yd3 (297 kg/m3). Typically bedding mixtures

contain [360 to 460] kg/m3 of cement, and [170 – 220] kg/m3

of Fly Ash.

|

|

An essential element in the proportioning of RCC for dams is the amount of paste.

The paste volume must fill or nearly fill aggregate voids and produce a compactable,

dense concrete mixture. The paste volume should also be sufficient to produce bond

and water-tightness at the horizontal lift joints, when the mixture is placed and

compacted quickly on a reasonably fresh joint. Experiences have shown that mixtures

containing a low quantity of cementitious materials may require added quantities

of non-plastic fines to supplement the paste fraction in filling aggregate voids.

Pozzolans

Use of Pozzolans in RCC mixtures may serve one or more of the following purposes:

1) as a partial replacement for cement to reduce heat generation; 2) as a partial

replacement for cement to reduce cost; and 3) as an additive to provide supplemental

fines for mixture workability and paste volume. The rate of cement replacement may

vary from none to 80 percent, by mass.

The selection of a Pozzolan suitable for RCC should be based on its conformance

with ASTM C 618. Class F and Class N Pozzolans are usually preferred, since they

normally contribute less heat of hydration than Class C and have greater sulphate

resistance.

Aggregates

The aggregates for RCC projects have to be been constructed with aggregates meeting

all the ASTM C 33 requirements, with the exception of an increased amount of fines

passing the No. 200 (0.075 mm) sieve. The American Concrete Institute (ACI) has

established aggregate gradation limits that have produced quality RCC pavement mixtures

[Figure 1 & Table 2].

Coarse aggregates

Consist of crushed or uncrushed gravel or crushed

stone while the fine aggregates consist of natural sand, manufactured sand, or a

combination of the two. Crushed aggregates typically work better in RCC mixes due

to the sharp interlocking edges of the particles, which help to reduce segregation,

provide higher strengths, and better aggregate interlock at joints and cracks. Because

approximately 80 percent of the volume of a high-quality RCC mix is comprised of

coarse and fine aggregates, they should be evaluated as to their durability through

standard physical property testing such as those outlined in ASTM C 33.

However, in RCC mixtures, the potential for segregation and the means of compaction

must also be primary considerations in selecting the maximum size of aggregate.

Early projects in the U.S. used a 3 in. (75 mm) nominal maximum size aggregate (NMSA);

however, a 2 in. (50 mm) NMSA is less prone to segregation and is becoming more

widely used.

The combined aggregate gradation should be selected to minimize segregation. A good

compactable RCC mixture is having a grading that is consistent and contains more

material passing the No. 4 (4.75 mm) sieve than typical in conventional concrete

of similar nominal maximum size aggregate. Gap-graded mixes that are dominated by

two or three aggregate sizes are not desirable for RCC.

Fine Aggregate / Fines

In low-cementitious materials content mixtures, supplemental fines, material passing

the No. 200 (0.075 mm) sieve, are usually required to fill all the aggregate void

spaces. Depending on the volume of cementitious material the fines may be 8 to 12%

of total solids by volume, or 12 to 16% by mass. Characteristics of the fines and

fines content will affect the relative compactability of the RCC mixture and can

influence the number of passes of a vibratory roller required for full compaction

of a given layer thickness. However, these fines need to be non-plastic with their

Plasticity Index (PI) not to exceed 4.

Chemical admixtures

Chemical admixtures have been effective in RCC mixtures that contain sufficient

water to provide a more fluid paste. ASTM C 494, Types A (water reducing) and D

(water-reducing and retarding) are the most commonly used chemical admixtures. Air-entraining

admixtures are not commonly used in RCC mixtures because of the difficulty in generating

the air bubbles of the proper size and distribution when the mixture has a no-slump

consistency.

|

Sieve Size

|

Percent Passing

|

|

Inch

|

Millimeter

|

Minimum

|

Maximum

|

|

3/4"

|

19.000

|

100

|

100

|

|

1/2"

|

12.500

|

70

|

90

|

|

3/8”

|

9.500

|

60

|

85

|

|

#4

|

4.750

|

40

|

60

|

|

#8

|

2.360

|

35

|

55

|

|

#16

|

1.180

|

20

|

40

|

|

#30

|

0.600

|

15

|

35

|

|

#50

|

0.300

|

8

|

20

|

|

#100

|

0.150

|

6

|

18

|

|

#200

|

0.075

|

2

|

8

|

Fig. 1 – Gradation

of CA for RCC

Reinforcement

It becomes necessary at times to embed reinforcing steel in RCC for the purpose

of anchoring various structural features. These structural features could be outlet

works structures, training walls for spillways, parapets, etc.

The reinforcement in the form of heavy welded wire mats provided in the RCC placement

will help to:

- Prevent the formation of wide cracks that might make the RCC susceptible

to deep abrasion-erosion from ash-laden flood flows,

- Provide bending resistance to limit cracking due to differential

settlement, and

- Provide shear-friction resistance across cracks to prevent blocks

of RCC, formed by perimeter cracking, from being dislodged by flood waters.

Mix Design

|

There currently exists several methods for proportioning RCC mixes for pavements;

however, there is not one commonly accepted method. The main RCC proportioning methods

include those based on concrete consistency testing, the solid suspension model,

the optimal paste volume method, and soil compaction testing. Whichever method is

employed, the goal is to produce an RCC mixture that has sufficient paste volume

to coat the aggregates in the mix and to fill in the voids between them. Regardless

of which

|

|

proportioning method is used, it is important that an RCC mixture meet the following

requirements:The fine and coarse aggregates should be chosen to achieve the required

density and to provide for a smooth, tight surface

- The moisture content should be such that the mix is dry enough

to support the weight of a vibratory roller yet wet enough to ensure an even distribution

of the cement paste

- The cementitious materials used should meet the required design

strength requirements at minimal cost with sufficient paste volume.

Selecting Mix Proportions

Procedure for Selecting RCC Mixture Proportions- Special concrete properties, such

as stress-strain characteristics, thermal properties, creep, etc., should be considered

during the material selection process and ultimately evaluated after the concrete

proportions are established. A comprehensive laboratory test program would normally

include a series of mixtures spanning the specified strength requirements with specialized

tests on selected mixtures in order to provide a comprehensive evaluation of the

materials.

|

Requirements

The requirements related to the properties of the RCC mixture are:

- Required/specified strength and age

- Expected exposure time and condition

-

Cementitious materials limitations and admixture requirements

-

Maximum size, source, and quality of aggregate,.

The mixture proportioning procedure is adopted as per the methods given in ACI 207.5R-99

based on the assumption that the concrete materials are suitable for the intended

use. For structural applications, the required average compressive strength (fcr)

should be determined using procedures described in EM 1110-2-2000 or ACI 214. However,

for normal mass concrete applications, these procedures may be somewhat overly conservative,

and a modified approach to establishing an over design factor and the required average

strength may be considered.

Process

RCC owes much of its economy to high-volume, high-speed construction methods. Large-capacity

mixers set the pace. Normally, RCC is blended in continuous-mixing pug mills at

or near the construction site. These high-output pug mills have the mixing efficiency

needed to evenly disperse the relatively small amount of water used. Dump trucks

transport the RCC and discharge it into an asphalt paver, which places the material

in layers up to 10 inches (250 mm) thick and 42 feet (13 m) wide.

When placing RCC during hot weather, it will be to the contractor’s advantage

to keep the concrete as cool as possible during

|

|

placement and compaction. As ambient air temperature increases beyond 90 degrees

F, the time allowed from time of mixing to completion of compaction should be reduced

accordingly (for example, from 60 minutes to 30 to 45 minutes). To compensate for

moisture loss during hauling and placement, additional mix water can be added at

the plant. For long haul times, consideration should be given to the use of hydration-stabilizing

admixtures to provide more workability time.

Compaction

Compaction begins immediately after placement and continues until the pavement meets

density requirements. There are two factors that should be considered when evaluating

hot-weather construction of RCC pavements: ultimate strength and workability.

Workability

Hot temperatures will make the concrete less workable and more difficult to place

and compact, resulting in a poorer quality final product. High temperatures lead

to higher rates of moisture evaporation, which is very important to monitor with

RCC because there is so little moisture in the concrete. As temperatures increase

from 700 F to 900 F[21.110C to32.220C]

the time to initial set and final set are reduced by 20 to 30 percent.

Curing of RCC

|

The optimal curing temperature for concrete is from 500 F to 700

F[17.780C – 21.110C]. When concrete is cured at temperatures

above 800F [23.330C] the early strengths (1, 3, 7 days) are

higher than concrete cured at normal temperatures. However, ultimate strength is

reduced 5 to 15 percent, if RCC is cured at 900F to 1050F

[32.220C to 37.220C] compared to curing at 730

F.

Construction specifications for RCC dams often require that the concrete mix temperature

not exceed 800 F. As with conventional concrete, curing is very important

for RCC. However, RCC has no bleed water, so the main concern is drying. At least

three negative things will happen if RCC is allowed to dry:

- The concrete will experience drying shrinkage which will lead

to cracking,

-

The cement will not continue to hydrate which will result in lower strengths and

less durability, especially at the surface, and

|

|

To keep RCC from drying the surface should be kept moist for 7 days or until a curing

compound is applied. The surface should be gently moistened with water from the

time compaction is complete. Curing compounds conforming to ASTM C 309 which are

used for conventional concrete can be used for RCC. However, because RCC has a more

open texture surface than conventional concrete, the curing compound application

rates are 1.5 to 2 times the application rates used for conventional concrete.

Effect of Temperature

Since heat of hydration is not a concern with RCC pavements, a better approach to

reduce the temperature of the concrete mix is to cool the coarse aggregate either

by shading the aggregate piles or sprinkling the piles with water. The water sprinkling

approach also aids in the mixing operation by providing moist aggregate which helps

assure a more uniform, consistent mixture.

Performance Evaluation of RCC

Properties important to the seismic analysis of RCC dams include compressive strength,

tensile strength, shear strength, modulus of elasticity, Poisson's ratio, and density.

Except for density, all these properties are strain-rate sensitive, and the strain

rates that occur during major earthquakes are on the order of 1,000 times greater

than those used in standard laboratory testing.

Properties

The properties of hardened RCC are similar to those of conventionally placed Mass

Concrete (CMC). Some properties will be determined by laboratory testing and some

will be assigned by the engineers. Some properties, like modulus of elasticity,

creep, and, to some degree, tensile strain capacity, are difficult to estimate without

testing.

Strength and Elastic Properties

The strength and elastic properties of RCC vary depending on the mixture components

and mix proportions in much the same manner as for CMC. Aggregate quality and cementitious

content are the principal factors affecting strength and elastic properties, but

these properties may be as much dependent on field control of mixing and placing

operations as on mixture ingredients or mixture proportions.

Compressive Strength

Common RCC mixtures may produce compressive strength ranging from 6.9 MPa (1000

psi) to over 27.6 MPa (4000 psi) at 1-year age. Most RCC projects have used mixtures

producing an average compressive strength between 13.8 and 20.7 MPa (2000 to 3000

psi) at 90-days to 1-year age.

Tensile Strength

Tensile strength can be measured by several methods, including the direct tension

method (CRD-C 164), the splitting tensile method (ASTM C 496), and the flexural

test or modulus of rupture method (ASTM C 78). The tensile strength is more dependent

on aggregate bond than compressive strength, hence the relationship between the

tensile strength and the compressive strength of concrete not only varies with the

method of test, but also varies with the type and maximum size of aggregate.

Direct Tensile Strength

Direct tension test results for RCC, similar to those for CMC, are lower than for

splitting tensile tests (often about 25 to 30 percent lower than splitting tensile

strength), The parent direct tensile strengths from a number of projects, using

both cores and cylinders, have ranged from 3 to 9 percent of the compressive strength,

with most values between 6 and 8 percent. If test strengths are based on wet-screening

and removal of aggregates larger than 38 mm (1.5 in.), test values for the full

mixture should be reduced by 10 percent.

Flexural Strength

Flexural strength, or modulus of rupture, is a measure of tensile strength. The

variation of this test is higher than other tensile tests and higher than that of

compressive strength. Available RCC data indicate that the Raphael (1984) relationship

of flexural to compressive strength is valid for RCC as well.

Lift Joint Direct Tensile Strength

Tables 4-1 through

4-3 present a means to determine preliminary lift joint direct

tensile strengths for design from splitting tension tests conducted on the parent

RCC. Lift joint direct tensile strength tests should be run on cast specimens and/or

cores from test placement sections to provide values for final design. Lift joint

direct tensile strength of RCC is sensitive to the maximum size of Low values of

lift joint direct tensile strength are based on natural, low strength aggregates

and embedded lift joints. High values of lift joint direct tensile strength are

based on all crushed, high strength aggregates and bedded lifts, aggregates, workability

of the mixture, degree of compaction, and age and condition of the lift joint surface.

Dynamic Tensile Strength

The dynamic tensile strength of RCC is considered equivalent

to the direct tensile strength multiplied by a factor of 1.50 This adjustment factor

applies to both the tensile strength of the parent material and to the tensile strength

at the lift joints, whether tested in direct tension, splitting tension, or modulus

of rupture. As with compressive strength specimens, the use of moist specimens for

the normal load strength tests is critical for this test procedure. Other tests

like Shear strength, Parent shear strength., Lift joint shear strength are also

to be conducted as per the requirements.

Modulus of Elasticity (E)

Properly proportioned and consolidated RCC should provide a modulus of elasticity

equal to or greater than that of CMC of equal compressive strength made with similar

materials. The modulus of elasticity is determined according to ASTM C 469 (CRD-C

19), or CRD-C 166.

Modulus of elasticity of RCC is similar to that of CMC and is about 6.9 GPa

(1 u 106 psi) at 1 day and ranges from about 21 to 38 GPa (3 to 5.5 u 106 psi) at

28 days and from about 30 to 47 GPa (4.3 to 6.8 u 106 psi) at 1 year. A low modulus

of elasticity is generally beneficial in reducing apparent stress and strain in

the structure.

Sustained Modulus of Elasticity

Includes the results of creep and can be obtained directly from creep tests Preliminary

design studies may assume the modulus of elasticity to be increased by 15 percent

for seismic load conditions and reduced by one third for long-time load conditions

where creep effects are important.

Poisson's Ratio

Poisson’s ratio is determined according to ASTM C 469. Poisson's ratio for

RCC is the same as for CMC. For static loads, most values range between 0.17 and

0.22, with 0.20 recommended when testing has not been performed. Poisson's ratio

is also strain-rate sensitive and the static value may be reduced by up to 30 percent

when evaluating stresses due to seismic loads.

Creep

Concrete with a high modulus of elasticity and high strength will generally have

relatively low creep. Low strength, low moduli mixtures have larger creep values.

Creep is determined according to ASTM C 512. The test method recommends five ages

of loading between 2 days and a year to fully define creep behaviour. Creep values

for a number of RCC projects are reported in ACI 207.5R. F(K) values for RCC have

ranged from 1.5 to 29 millionths per MPa (0.01 to 0.2 millionths per psi), with

the higher numbers corresponding to lower compressive strength mixtures. The effects

of creep can also be considered by using the sustained modulus of elasticity of

the concrete measured during the period of loading (ACI 224R, ACI 207.1R).

Thermal Properties

The coefficient of thermal expansion for CMC and RCC varies between 7 and 14 millionths

per qC (4 and 8 millionths per qF). A value of 9 millionths per qC (5 millionths

per qF) can be used for preliminary RCC design studies. The ratio of TSC /coefficient

of thermal expansion is a rough indicator of the temperature drop required to produce

cracking and can be used to compare the ability of various materials combinations

(particularly aggregates) to resist thermal cracking.

Durability

RCC, like CMC, is subject to potential deterioration due to the effects of abrasion/erosion,

freezing and thawing, and other factors such as alkali-silica reaction expansion

and sulphate attack. Performance, discusses historic performance of RCC hydraulic

structures subject to deterioration from some of these factors.

Permeability

Permeability of the RCC mass and of the horizontal lift surfaces are key elements

for hydraulic RCC structures. Test values for well-compacted, workable RCC mixtures

typically range from 1.5 to 150 u 10-8 mm/sec (0.3 to 30 u 10-9 ft/min).

Density

Density is determined according to CRD-C 23. Density of RCC depends primarily on

aggregate density and the degree of compaction. Typical values of density for CMC

range from 2240 to 2560 kg/m3 (140 to 160 lb/ft3).

Abrasion/Erosion Resistance

Abrasion/erosion resistance is primarily governed by compressive strength of the

RCC and quality of the aggregate as per ASTM C 1138. RCC mixtures with a low water-cementitious

material ratio and large-size aggregates are expected to provide erosion resistance

equal to a conventional concrete with similar ingredients.

Resistance to Freezing and Thawing

RCC mixtures do not normally have intentionally entrained air and consequently will

not have a high resistance to freezing and thawing in a critically saturated moisture

condition. However, many examples of good field performance exist for RCC that is

not critically saturated. RCC subjected to ASTM C 666, typically performs poorly.

Most RCC mixtures require a high dosage of air-entraining admixture to be effective,

and percentages of air entrained in RCC will usually be more variable when compared

with CMC

Design Requirements for RCC Gravity Dams

The principles of design specified in EM 1110-2-2200, “Gravity Dam Design,”

apply to RCC gravity dams.

Uplift within the body of an RCC dam -

Uplift within the body of an RCC dam constructed with mortar bedding on all lift

joint surfaces can be assumed to vary in accordance with the requirements for conventional

concrete gravity dams. When mortar bedding is not used, uplift within the body of

the dam shall be assumed to vary from 100 percent of headwater at the upstream face

to 100 percent of tail water (or zero, as the case may be) at the downstream face.

Minimum sliding factors of safety for RCC gravity dams

- Drains in the RCC dam are recommended to ensure that seepage along lift joints

is controlled and that uplift is minimized. The minimum factors of safety required

for sliding stability of RCC gravity dams will be as required in EM 1110-2-2200

for conventional concrete gravity dams. A preliminary cohesion design value of 5

percent of the compressive strength is recommended for lift joint surfaces that

are to receive a bedding mortar; otherwise, a value of 0 should be assumed. The

angle of internal friction can vary from 40 to 60 deg.

Seepage Considerations – The joints between

RCC lifts can be a major pathway for potential seepage through an RCC dam. Cracks

resulting from thermal volume changes, foundation irregularities, and poorly consolidated

RCC along the foundations, abutments, and embedded features are the other potential

major pathways for seepage. Properly proportioned, mixed, placed, and compacted

RCC should make as watertight a structure as conventional concrete. Seepage can

be controlled through appropriate design and construction and using any of the following

methods selected suitably.

- Membrane systems

- Drainage systems

- Considerations for “dry” dams

Case Study

|

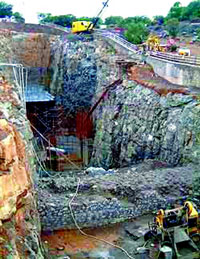

Ghatghar Dam Project, India

Ghatghar Pumped Storage Scheme a hydropower

generation project of 250 MW capacity, is the first dam in India constructed using

Roller Compacted Concrete (RCC) technology. It is constructed by Irrigation Department

Govt. of Maharashtra. Maharashtra is the third largest state of India, in area as

well as in population. In shape it is four sided with the western side on the Arabian

Sea. The smallest side is the eastern side, which borders Madhya Pradesh, with Gujarat

to the north and Andhra Pradesh, Karnataka and Goa to the south.

It may be recalled that the State Government of Maharashtra had announced in its

2002-03 budget that it proposed an additional 654.25MW of installed capacity for

its hydroelectric projects. This included 250MW for the Ghatghar Pumped Storage

Hydro Electric Project as well as 391.5 MW for the Sardar Sarovar scheme, an inter-State

project that will benefit Gujarat, Rajasthan and Maharashtra.

Location

The Ghataghar Dams Project is located on the boundary of the Thane and Ahamadnagar

districts of the Maharashtra State. The Ghataghar Dams consists of three dams -

|

|

Upper Dam, Saddle Dam-1 and Lower Dam, constructed under this scheme with

Roller Compacting Concrete Technology by using dry fly ash with cement. The

lower reservoir and surge well is located in the Sahyadri Range near the village

of Chonde, Shahapur taluka, Thane district. The upper portion of this scheme is

located near village Ghatghar, Akole taluka, Ahmednagar district. Saddle Dam

No. 1, Upper Dam and Lower Dam are built in Roller Compacted Concrete.

A record concreting of over 6, 50,000 m3 in 12 months

was achieved by Patel Engineering Ltd at Ghatghar Roller Compacted Concrete Dam

project.

Dam Details

The upper dam is a gravity dam about 478 m long and 15.50 m high located on Pravara

River near Nashik. It provides storage of 5.87 million cubic metres required

for the operation of the pump storage scheme. The lower dam is also a gravity

dam about 390 m long and 82 m high at the deepest section located on Shai Nalla

at the foot of the continental divide. It provides gross storage of 3.80 million

cubic metres.

Budget

The project was started with an estimated cost of Rs 1,184 crore. On the cost

front the project got a blow - escalating the cost to Rs 1,300 crore. While Rs 400

crore has come in from Japanese Bank of India Co-operation (formerly known as the

Overseas Economic Co-operation of Japan), another Rs 400 crore from the Power Finance

Corporation, and the remaining from the Government of Maharashtra.

Duration

Having started in 1994, the Ghatghar Dams Project was due for completion in

2005, but completed in 2007.

Construction and Contractor

|

The principal contractor for the overall programme is Japan's Nissho Iwai Corp,

with Japanese engineering company, J-Power, providing project management throughout.

J-Power also provided consultancy in 1994 prior to the construction phase, which

started in 1995.The main contractor for the roller compacted concrete dam work is

Patel Engineering Ltd of Jogeshwari, Bombay. The use of fly ash is being regarded

as an innovative approach to the roller compacted concrete method of construction.

Dirk India Ltd has supplied more than 80,000t of Pozzocrete to the project. It consists

of a downstream vertical shaft of 130m with an 11m diameter, excavated near the

lower reservoir. The Central Mining Research Institute (CMRI) in Nagpur designed

the blasting method for the excavation of the 122m-deep pilot shaft, which was carried

out by contractor R.J. Shah and Co from Bombay. Long hole raise blasting is considered

one of the most economic vertical shaft methods. It is safe and does not involve

cumbersome procedures. It does, however, require a meticulous drilling and blasting

strategy. In the

|

|

Ghatghar vertical shaft, the final 85m was blasted in only

20 days.

Advantages

Advantages of using Roller Compacted Concrete in Dam Construction - The main benefit

of RCC is efficient and speedy construction: the project was completed in

just two years; otherwise about 10 years are required if conventional concrete is

used to construct these dams. The other advantages are higher substitution (up to

70 per cent) of cement by fly ash and reduced heat of hydration, consequently lesser

expenses on cooling infrastructure.

Mechanization of Concrete Laying

Two Schwing Stetter Concrete Batching and Mixing plants – Models HN 3.0 (120

m3/hr) and one HN 4.0 (160 m3/hr) were installed aggregating

to 400 m3/hr batching capacity. The plants had twin shaft mixers and

the control system was Stetter MCI 300 system Principal designers of the project

are EPDC, Japan, in association with Tata Consulting Engineers, India and Malcolm

Dunstan and Associates (MD&A) U.K.

Details of Roller Compacted Concrete Work

Different methods of delivery of RCC into the dam body were studied and finally

best option was selected and the entire site layout was finalized. As per the layout

all the equipment were erected. It was decided to place RCC in two halves so as

to avoid un-planned cold joints.

The RCC delivery system comprised of belt conveyor delivering 400 m3

/hr. Four water chilling plants were installed for chilled water supply to three

batching plants and ice plants. Two crushing and screening plants for aggregates

production were installed. One 250 TPH crushing plant and 100 TPH were deployed.

Two 120 TPH and one 150 TPH ice flake plant were commissioned, having automatic

ice handling system. Equipment for RCC placement on dam body comprised of 20-ton

dump trucks for collecting RCC from Belt conveyor and truck unloader, D-5 dozer

for spreading RCC, 10-ton vibratory roller for compaction. It also includes Cranes

for form erection and many other minor equipment like high frequency vibrators,

small roller etc.

The RCC placement was planned to complete in 16 working months excluding one monsoon

of four months. Total 250,000 cum of RCC was placed in the first season. Balance

45,000 cum was to be placed in the next season. Total of more than 6, 50,000 cum

or concrete was placed in 12 working months.

RCC Cooling

|

The temperature of RCC had to be maintained at the placement point between 17-22o

C accordingly the RCC cooling system was designed. Maintaining temperature in this

bracket required pre-chilling of aggregates, use of chilled water and flake ice.

Hence, wet belt conveyor system designed by IIT, Bombay for chilling aggregates

from temperature as high as 43oC was used. This required 1200 TR integrated

water-chilling plant and other sub-systems like water filtration plant, water recirculation

pump, pipeline network and so on.

Major Highlights

Total Concrete Quantity of Roller Compacted Concrete used in 16 Months - 6, 10,903

m3 (Dec 04-Apr 06) (June to Oct 06-no work) resulting in a pouring rate

of Average of 50,908 m3 per month.

Down Pumping

With the same SCHWING BP 25 E at R J Shah & Co. the BP250 was used to pump M25

grade concrete down through 88 mtr. Pipeline which included 04 nos.90 degree bends

and 07 nos. S bends. The Level Difference between pump and point 72 mtrs. (Down),

Top Shot Mobile TSM 30.10 was used extensively for shotcreting of the tunnels.

Concrete Pumping record for the Tunnel Shaft Vertical Pumping was made With a Schwing

BP 250 HDE Concrete Pump, Concrete M/s R.Shah & Co. pumped M25 grade concrete

through a distance of 30 mtr horizontal and 67 mtr vertical.

The Ghatghar Dam Project, the first dam in India constructed using Roller Compacted

Concrete (RCC) technology which was started in the year 1994 was awarded in November

2001 for its technical expertise for the construction of the RCC Dam.

- Conveyor system with self-propelled crawler-placer

- Conveyor system with mobile side discharge belt

- Transverse contraction joint construction with plastic-wrapped

joint form

- Installation of water stop, joint drain, and crack initiator

Conclusion – 26% of the dams build worldwide

have used RCC in the year 1985, which reached 50% in 2005 indicating the popularity

of technology and the pace of development. The application of RCC in India

was nil in 1990 and is 5% in the year 2008. Roller Compacted Concrete Technology

is gaining its popularity year by year gradually but steadily entering the construction

industry.

|

|

Acknowledgement – Authors acknowledge the web- links and websites from which

materials are drawn for this article.

1. Reference - Ghatagar Dams Project, Maharashtra,

India - [http://www.water-technology.net/projects/ghatagar/]

- India's first 84-m high Roller Compacted Concrete dam, Projectmonitor

– The Newspaper [http://www.projectsmonitor.com/detailnews.asp?newsid=7197]

- ACI 207.5R-99, Roller-Compacted Mass Concrete, Reported by ACI

Committee 207

- Gilbert Gedeon, P.E, Roller Compacted Concrete, Course No: S08-001,

Continuing Education and Development, Inc., Stony Point, NY, info@cedengineering.com

Bharathi Ganesh,Associate Professor, Civil Engg. Dept, Global Academy of Technology,

Bangalore

Dr. H. Sharada Bai, Professor, Dept. of Civil Engg. UVCE, Bangalore University,

Bangalore