Sika Concrete Protection systems

Introduction

In the 21st Century, concrete bridges or civil engineering structures are built to last not for ever but at least for more than 100 years. The two most universal causes of reinforcement corrosion are carbonation and chloride attacks. The faster these penetrate the concrete, the sooner the passive layer around the reinforcement bars is destroyed and corrosion process initiated. The protective coatings are widely used for concrete protection of a civil engineering structures.

To ensure this long lasting durability, appropriate maintenance strategy shall be taken by the bridge designers/owners. Protective coating can be part and parcel of the long lasting durability strategy for new structures but as well as to increase the durability of the existing ones.

The exposure condition on a structure has an influential role on its durability. Decision to use or not a protective coating shall be taken after thorough consideration as described in the following logigramme.

Survey/Diagnostic

Prior to consider the use of protective coating, appropriate survey shall be conducted in order to determine the cause of potential and existing problems so that the coating protective functions can correctly addressed these issues.

|

Pathology

|

Freeze-thaw (+salt)

|

Alkali Silica Reaction

|

Sulphate

|

Rain water

|

CO2

|

Cl-

|

|

Non-destructive testing

|

|

Open porosity

|

X

|

|

|

X

|

X

|

X

|

|

Concrete cover

|

X

|

|

|

X

|

X

|

X

|

|

Reinforcement corrosion

|

X

|

|

|

X

|

X

|

X

|

|

Electro-chemical measurement (potential, corrosion rate, etc.)

|

X

|

|

|

X

|

X

|

X

|

|

Cracks visualization

|

X

|

X

|

X

|

|

|

|

|

Destructive testing

|

|

Carbonation front

|

|

|

|

|

X

|

|

|

Permeability to Cl-

|

|

|

|

|

|

X

|

|

Level of Cl- in the concrete at rebar level

|

|

|

|

|

|

X

|

|

Entrained air network

|

X

|

|

|

|

|

|

|

Mechanical strength (compressive, flexural, etc.)

|

X

|

X

|

X

|

|

X

|

X

|

|

Density

|

X

|

X

|

X

|

|

X

|

X

|

|

Petrography analysis

|

|

X

|

X

|

|

X

|

X

|

|

Expansion potential

|

|

X

|

X

|

|

|

|

|

Chemical analysis

|

|

X

|

X

|

X

|

X

|

X

|

As example, in order to address the relevant issues, the following tables indicate the relevant tests to be performed according to the pathology encountered.

|

Principle No

|

Principle and its definition

|

Method based on the

principle

|

Sika system /

Products

|

|

Principle 1

(PI)

|

Protection against ingress

Reducing or preventing the ingress of adverse agents, e.g. water, other liquids, vapour, gas, chemicals and biological agents

|

1.1 Hydrophobic Impregnation

Deep penetrating hydrophobic impregnation

|

Sikagard-705 L,

|

|

1.2 Impregnation

Applying liquid products which penetrate the concrete and block the pore system

|

-

|

|

1.3Coating

with & without cracks bridging properties

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

|

Principle 2

(MC)

|

Moisture Control

Adjusting and maintaining the moisture content in the concrete within a specified range of values

|

2.1Hydrophobic Impregnation

|

Sikagard-705 L,

etc.

|

|

2.2Impregnation

|

Sikafloor Cure Hard -24

|

|

2.3Coating

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

|

Principle 8

(IR)

|

Increasing Resistivity

Limiting the moisture ingress to raise the resistivity of the concrete to a level where the corrosion rate is insignificant

|

3.1 Hydrophobic Impregnation

|

Sikagard-705 L,

etc.

|

|

3.2Impregnation

|

Sikafloor Cure Hard -24

|

|

3.3Coating

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

|

| A. Corrosion Inhibitors |

|

| B. Hydrophobic Impregnation |

Different kinds of concrete protection system

The various forms of concrete protections systems are

- Corrosion Inhibitors ( For Reinforcement)

- Hydrophobic Impregnation (Water repellent system)

- Coatings ( film forming system)

C. Coatings

A. Corrosion Inhibitors:

An inhibitor is a substance that reduces the rate of a chemical reaction. A corrosion inhibitor is a substance that delays the start of corrosion and/or reduces the risk of corrosion.

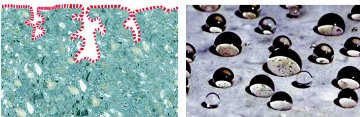

B. Hydrophobic Impregnation:

It is a treatment of concrete to produce a water-repellent surface. The pores and capillaries are internally coated, but they are not filled. There is no film on the surface of the concrete and there is little or no change in its appearance

C. Coatings:

Treatment to produce a continuous protective layer on the surface of concrete

Selection guide for concrete protection system

The surface protection can now be selected. As a guide, the recommendation given in the European Standard EN 1504-9 (Edition Sept-08) can be followed and described as below:

|

Principle No

|

Principle and its definition

|

Method based on the

principle

|

Sika system /

Products

|

|

Principle 1

(PI)

|

Protection against ingress

Reducing or preventing the ingress of adverse agents, e.g. water, other liquids, vapour, gas, chemicals and biological agents

|

1.1 Hydrophobic Impregnation

Deep penetrating hydrophobic impregnation

|

Sikagard-705 L,

|

|

1.2 Impregnation

Applying liquid products which penetrate the concrete and block the pore system

|

-

|

|

1.3 Coating

with & without cracks bridging properties

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

|

Principle 2

(MC)

|

Moisture Control

Adjusting and maintaining the moisture content in the concrete within a specified range of values

|

2.1 Hydrophobic Impregnation

|

Sikagard-705 L,

etc.

|

|

2.2 Impregnation

|

Sikafloor Cure Hard -24

|

|

2.3 Coating

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

|

Principle 8

(IR)

|

Increasing Resistivity

Limiting the moisture ingress to raise the resistivity of the concrete to a level where the corrosion rate is insignificant

|

3.1 Hydrophobic Impregnation

|

Sikagard-705 L,

etc.

|

|

3.2 Impregnation

|

Sikafloor Cure Hard -24

|

|

3.3Coating

|

Sikagard-550W Elastic,

Sikagard-680 MY etc.

|

As example given in the EN 1504-9, for protection against ingress (P1), moisture control (P2) and increasing resistivity (P8), the following systems can be proposed as protection for further deterioration.

functional requirements of coatings

Functional Requirements of Coatings

According to the level and type of protection required, the material shall present the following characteristics:

- Resistance to freeze thaw cycles (Coating & hydrophobic impregnation)

- Resistance to de-icing salts (Coating and hydrophobic impregnation)

- Weathering resistance

- Prevention of water ingress

- Breathable

- Impermeable to carbon dioxide

- Compatible with repair system

- And in function of the requirement, able to withstand micro cracking.

- Deep penetration and alkali resistance (for hydrophobic impregnation)

Selection of coatings system based on Level of protections.

Depending on the levels of protection required, the protection can be classified as

- Level -I : Durable Concrete Protection (Sikagard deep penetrating hydrophobic impregnation)

- Level -II : Durable Concrete and Reinforcement Protection (Sika FerroGard Corrosion inhibitor + Sikagard deep penetrating hydrophobic impregnation)

- Level -III : High Performance protection for Extreme Conditions (Sika Ferrogard Corrosion inhibitor + Sikagard deep penetrating hydrophobic impregnation + Sikagard Protective Coatings)

Emerging trends based on various technologies

The below listed technologies are the emerging trends in concrete protection system. Sika offers for the civil engineering structure owners a wide selection of coating materials products but not limited to,

|

Technologies

|

Advantages

|

Sika Product

|

|

A surface applied corrosion inhibitor, designed for use as an impregnation of steel reinforced concrete.

|

- Does not alter the water vapour diffusion properties of concrete

- Long term protection and durability

- Protects both, cathodic (principle 9) and anodic (principle 11) zones of reinforcing steel

- Economic extension of the service life of reinforced concrete structures

- Easy, economical application,

|

Sika® FerroGard®-903

|

|

A hydrophobic Impregnations coatings one component, low viscosity, reactive impregnation for concrete and cementitious substrates based on silanes with 99% active ingredient

|

- Excellent penetration

- Economic and easy to use

- Reduces capillary water absorption, protection against driving rain and splashing on vertical areas

- Reduction of absorption of aggressive or deleterious agents dissolved in water

- No change in water vapour permeability

- Long term efficiency, deep penetration

- Increases the resistance of concrete to freeze and thaw cycles and de-icing salts

- Resistant to sea water

- Low VOC content

|

Sikagard®-705 L

|

|

Acrylic based, single component, plasto-elastic crack bridging protective coating.

|

- Crack-bridging

- High diffusion resistance against CO2 reducing the rate of carbonation

- Water vapour permeable

- Very good resistance against weathering and ageing

- Environmentally friendly (solvent free)

- Reduced tendency to dirt pick up and contamination

|

Sikagard®-550 W Elastic

|

|

High performance methyl methacrylate (MMA) compositions for protection and decoration on concrete, masonry and steel structure

|

- Excellent weather resistance

- Protects the concrete against aggressive atmospheric influences, which can penetrate into the concrete in the form of salts or gases

- Very high diffusion resistance against carbon dioxide

- Excellent resistance to dirt pick-up

- Highly UV-resistant

|

Sikagard®-680 MY

|