STEEP ANGLE CONVEYOR IN BUILDINGS

T.Venkatesh Rao, R.Ravichandran M.Balasubramani, T.Palaniappan

1. General Manager - Edrc, Mmh I/C, Larsen & Toubro, Chennai

2. Joint General Manager (Design - Civil & Structural), Edrc, Mmh I/C, Larsen & Toubro, Chennai

3. Chief Engineering Manager (Design - Civil & Structural), Edrc, Mmh I/C, Larsen & Toubro, Chennai

4. Engineering Manager (Design - Civil & Structural), Edrc, Mmh I/C, Larsen & Toubro, Chennai

|

Conveyor system

A conveyor system is a common piece of mechanical handling equipment that moves large quantity of Bulk materials such as Iron Ore, Coal, Flyash, Rock Phosphate etc; from one location to another. Conveyors are especially useful in applications involving the transportation of heavy or bulky materials which are required in large volumes. Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular in the material handling and packaging industries. Many kinds of conveying systems are available, and are used according to the various needs of different industries. These being highly automated in nature, requires minimum manpower to operate. Conveyor systems are used widespread across a range of industries due to the numerous benefits they provide. |

|

- Conveyors are able to safely transport materials from one level to another, which when done by human labor would be strenuous and expensive.

- They can be installed almost anywhere, and are much safer than using a forklift or other machine to move materials.

- They can move loads of all shapes, sizes and weights. Also, many have advanced safety features that help prevent accidents.

- There are a variety of options based on the applications which include hydraulic, mechanical and fully automated systems.

Application

Conveyor belts are widely used in mineral industry. Underground mine transport, opencast mine transport and processing plants deploy conveyor belts of different kinds to adopt the specific job requirements. The main advantages of conveyor belt system are:

1. A wider range of material can be handled which pause problems in other transportation means. Belt conveyor can be used for abrasive, wet, dry, sticky or dirty material. The lump size of the transported material is limited by the width of the belt. Belts up to 2500 mm wide are used in mining industry.

2. Higher capacity can be handled than any other form of conveyor at a considerably lower cost per tonne kilometer. Conveyor belts with capacity of 11000t/h and even higher can be deployed to match with higher capacity mining machinery.

3. Longer distances can be covered more economically than any other transportation system. A single belt conveyor or a series of belt conveyors can do this. Belt conveyors can be adopted for cross-country laying.

4. By the use of many forms of ancillary equipment such as mobile trippers or spreaders bulk material can be distributed and deposited whenever required.

5. Many other functions can be performed with the basic conveying like weighing, sorting, picking, sampling, blending, spraying, cooling, drying etc.

6. Structurally it is one of the lightest forms of conveying machine. It is comparatively cheaper and supporting structures can be used for many otherwise impossible structures such as crossing rivers, streets and valleys.

7. The belt conveyor can be adopted for special purposes (fire resistant, wear resistant, corrosion resistant, high angle negotiation etc.) and can be integrated with other equipment.

8. It can be horizontal, incline or decline or combination of all.

9. Minimum labour is required for the operation and maintenance of belt conveyor system.

10. In underground mine transport, belt conveyor can be used in thin seams as it eliminates the rock works that might otherwise be required to gain haulage height. Moreover, belt conveyor can provide continuous haulage service from pit bottom to the surface.

Types of Conveyors

- Open Belt Conveyors

- Pipe Conveyor

- Bucket Chain Conveyor

- Screw Conveyor

- Pneumatic Conveyor

- Steep Angle Conveyor

Limitations of Conventional Belt Conveyors

The major limitations of conventional belt conveyors are usually considered to be:

- Low angle of lift. The angle varies depending on the angle of repose of the material being conveyed. Usually about 20 less than the angle of repose, typically this means 16 - 20 angle of lift.

- The difficulty to negotiate tight curves. Traditional troughed belts have a limitation on horizontal radii capabilities. At best seldom below 500 m radius for fabric construction and about 1500 m radius for steel cord reinforcement on horizontal radii.

- The difficulty to economically protect the conveyed product from the environment and vis versa.

The first two limitations:

- Low angle of lift

- Difficulty to negotiate tight curves,

have received the most attention, particularly in the last 20 years. The impact to and from the environment becoming increasingly important only in the last 10 years, largely because of the cost of labour. In many cases the separation of material and the environment almost happening by accident due to the solving of other limitation.

Advantages of Steep angle Conveyor

- Within the building, transport of material from one level to other level

- High angle of lift (Around 90’)

- Revamping of existing buildings

- Less space utilization

- Less Maintenance

Steep Angle Conveyor

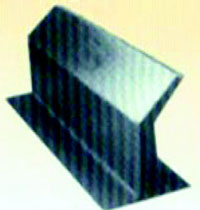

It is an integrated combination of Belt Elevator and Belt conveyor. The belt conveyor usually requires longer length due to limitation of inclination (16 - 180) whereas Bucket elevator is very prone to frequent maintenance. Hence where space is limited STEEP ANGLE CONVEYORS with maintenance free feature is the only viable solution. The system is economical and having less power consumption than an equivalent belt conveyor. Fig:1 & Fig 2 shows the arrangement of the same.

|

|

| Steep angle Belt with Pulleys |

Steep angle arrangement in Steel building |

|

Steep Angle Conveyor Belts are modern age Bucket Elevator Box Belts. These Belts are made with Cleats and Sidewall. The concept of steep angle belts is to carry materials on steepest angle upto 90 degree with zero spillage. These belts can be driven at the speed upto 5 M/sec. The space requirement is quite less as compared to Conventional Belts.

Base Belts: Base Belt plays a key role in steep angle Conveyor Belts, The base belts are made with special cross rigid Member design to get more stability and rigidity.

|

|

The different design of cross rigid belts are available with Indus `CTR`, Indus `CBR`, Indus `CDR`.

Side Wall: The side wall has been designed to achieve adequate rigidity to avoid the buckling under compression experienced by it at the point of deflection. The top portion of the side wall has been designed against tear & gauging resistant by using special rubber compound having high elongation at break. The side walls are fully reinforced with Synthetic fabric to get better life.

|

Steep angle conveyor side walls |

|

| |

“K” Type cleats |

Cleats: Cleats are designed with proper rigidity to preclude excess backward bending due to gravitational force exerted by the material loaded in cleats. By seeing critical application, It had modified all type of cleats with Synthetic fabric reinforcement to avoid tearing due to material gravitational force. Type `T`, `K` and `TKS` charts are reinforced with metal fasteners through side wall.

Implications

Steep angle conveyors are now extensively used in buildings as it has fetched increasing advantage in material handling. It had been implemented for Bhushan Steel Limited to its integrated Steel Plant at Meramandali, near Angul in Orissa from 3MTPA to 6MTPA stage. It comprises of raw material preparation & Handling system. It includes material handling equipment mainly comprising of Belt conveyors, Crushers, Screens, Slewable stacker, Barrel type reclaimers, High angle conveyors, Transfer cars, Coal washeryetc.;

System description

Uncrushed coal (Lump size -300 mm) received from conveyor will be sent to Coal Bunker at Primary Screen & Crusher House (3PSCH) through Belt Conveyor & Reversible Shuttle Conveyor. From the Coal bunker, uncrushed coal will be fed to four numbers of Roller Screens by four sets of Rod Gates, Manual Rack & Pinion Gates and Vibro Feeders. Separation size of Roller Screens is 75 mm. Oversize coal (+75 mm) from the roller screens will be sent to four numbers of Double Roll Crushers where the coal is crushed to -75 mm size and discharged to conveyors via four numbers of diverter gates. On the other hand, the undersize coal (-75 mm) from the roller screens will be transferred to conveyor via four numbers of reversible conveyors & two numbers of Belt Feeders.

The crushed coal and oversize coal from Flip Flow Screens at Secondary Screen House on conveyor will be transferred to three numbers of high angle conveyors (Rated Cap. 1200 TPH each) at Primary Screen & Crusher House (3PSCH) by means of motorized Diverter Gates. Inline magnetic separators will be placed over the head end of conveyors. Also, belt weigh scales, will be placed on conveyors respectively. The high angle conveyors(Refer Fig:6) will feed the coal to Coal Bunker (Cap. 1000 T) of Secondary Crusher House (3SCH) via reversible shuttle conveyors . From the bunker, the coal will be fed to four numbers of reversible Hammer Mills via four sets of Rod Gates, motorized Rack & Pinion Gates and Vibro Feeder for reducing size of coal to (-)6 mm. Hammer Mill outputs are loaded to Belt Feeders via four numbers of motorized diverter gates.

Size of input coal for washery through conveyor is 6 – 20 mm. For feeding washery, suitable change of setting of Hammer Mill shall be done for getting lesser quantity of (-)6 mm size in crushed coal compared with requirement for power plant.

|

It had been used to transfer uncrushed coal (Lump size -300mm) in two sets of crusher house (Primary Screen & Crusher House , Secondary Crusher house) for reducing coal to get a final size of (-6mm) for power plant feeding. This had reduced the conventional length of around 200m conveying length to reach such a lift with also reduction in space in the plant.

Conclusion

Uses of Steep angle conveyors in buildings have increased advantage when space restriction is there & even maximum lift of 200m is available currently. Comparing to conventional conveyor it will savings in both cost & construction time.

|

|

Reference

- Tad S.Golosinski,Mahinda D.Kuruppu & Songnian Zhao , ‘Development of Steep angle conveyor for surface mining applications, Mining Science & Technology,99 Xie & Golosinski (eds) 1999,Balkerma,Rotterdam,ISBN 905809067 1

- J.R.McTurk & N.Birdsey , ‘The Specialised Belt Conveyors,

- Christof Brewka & Ingolf Neubecked , ‘Steep angle Pipe Conveyor”, Greenwood village,CO.U.S, Published:2008-11-20

- Mulukhov, K., Steep Angle Conveyor for Bulky Run –Of-Mine Ore,SME Transactions Volume 312,2002,Section-3

- Belt Conveyors for Bulk materials – Fifth edition – Copyright @1997Conveyor equipment manufacturer’s association

- RAVASCO – “Steep Angle Conveyor Belts