Can Glass Be as Strong as Concrete

Researchers at the University of California, Los Angeles (UCLA), who are working in collaboration with colleagues at the Université Pierre et Marie Curie in Paris on a method to make stronger glass with better aging properties, recently made a surprising discovery. If glass is placed under tremendous pressure as it cools, it develops enhanced atomic bonds that are similar to those that bolster the connections in a steel truss building.

"It was, I think, quite unexpected to see that this theory that has been developed for macroscopic structural trusses can actually be applied to atomic networks—to find some optimal structures, but on the atomic scale," says Mathieu Bauchy, Ph.D., an assistant professor of civil and environmental engineering at UCLA.

Bauchy and Matthieu Micoulaut, Ph.D., a professor of materials science at the Université Pierre et Marie Curie, recently published their findings, " Densified network glasses and liquids with thermodynamically reversible and structurally adaptive behaviour," in the journal Nature Communications.

Bauchy notes that glass is essentially a frozen liquid that begins at a very high temperature and is cooled quickly to avoid crystallization. Because of this, glass is susceptible to temperature variations and tends to shrink over time, becoming increasingly brittle. "The basic question that we are trying to address is, how can we design a material that virtually does not age over time?" Bauchy says.

The researchers used molecular dynamic simulations, which establish the atomic structure of a material and then convert this information to macroscopic properties. By beginning with the atomic structure and reproducing the industrial methods used to synthesize glass, Bauchy and Micoulaut found that putting glass under very high pressure as it cools improves the atomic structure. The ideal pressure window is between 2 and 12 Giga Pascals.

"We find that within a certain window of pressure ...you can actually design some glasses that show very strong resistance to aging," Bauchy says. "The main finding is those glasses that are virtually not aging have an atomic structure which is very similar to what you would find with mechanical trusses. Using the vocabulary of structural engineers, you would call it statically determinate."

In addition to pressure, the researchers found that changing the proportions of chemicals in the glass formula can also change the number of atomic bonds, making glass stronger. "It really is something that can potentially be a game changer, in the sense that glass for so long has been seen as a brittle material. That is true. If you take the typical glass of your window, it is ...brittle. But it doesn't necessarily have to be this way," Bauchy says.

|

|

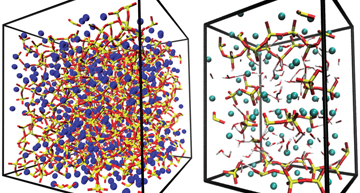

| Researchers have found that the degree of atomic disorder of typical silicate glasses, left, and concrete, right, are remarkably comparable and can be changed to produce stronger materials. © Mathieu Bauchy |

Manipulating the ingredients of glass could create a radically different material in the future, adds. "It is realistic to think that over the years we will be able to produce glass that will be almost unbreakable. When you do that, it means that you can start to use glass as a viable alternative to a typical concrete for infrastructure. It starts to have the same properties in terms of strength and reliability," Bauchy says. But of course, it would have the added advantage of transparency.

Because concrete shares some atomic structures with glass, Bauchy and his colleagues at UCLA are also examining methods of improving concrete, in separate research. Although the extreme pressures used in the glass research are impractical for concrete structures, early indications are that changes to the chemical composition of such ingredients as cement improve the aging properties of concrete as well.

|

"What we find is that we can apply similar tools for both glasses and cement, because we are facing the same challenges for both materials," Bauchy says. "We want to improve their mechanical properties, improve their resistance to fracture, improve their strength, and also improve their durability over time. It makes sense to use the same tools to approach the problems faced by both the glass and the cement industries." |

Preliminary findings indicate that by changing the calcium-to-silicon ratio in Portland cement from 1.7 to 1.5, the resulting concrete would have significantly better aging properties and greater resistance to creep. In preliminary findings, this change also improves fracture resistance, and dissolution over time, with the added benefit of reducing CO 2 emissions.

|

"Obviously, when you start to deal with cement-based [materials] and concrete,it becomes much more difficult, because they are multiscale materials—highly heterogeneous—inwhich some chemical reactions go on over time. It is much more challenging. |

"We think that based on our results in glasses that we can now have an impact on concrete, which is by far the most manufactured material on the Earth," Bauchy explains. "So we think that we can have a much higher impact by tackling this material."