An Overview of Construction & Demolition Waste Recycling

Building materials account for about half of all materials used and about half the solid waste generated worldwide. They have an environmental impact at every step of the building process—extraction of raw materials, processing, manufacturing, transportation, construction and disposal at the end of a building's useful life.

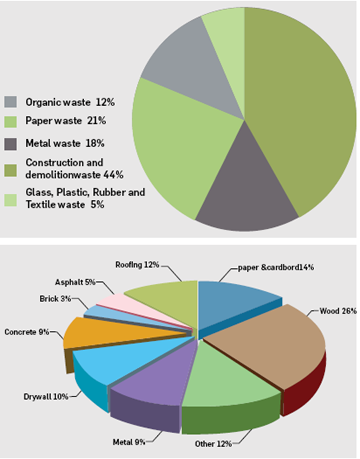

Construction and demolition (C&D) waste is a general term for a diverse range of materials that, when segregated, can include high-value materials and resources for new construction. The definition of C&D waste is waste produced by demolition and building activities, including road and rail construction and maintenance and excavation of land associated with construction activities. The C&D waste stream usually covers only some of the generation, disposal and recycling of C&D wastes, as these materials can also be found in the Municipal Solid Waste (MSW) and Commercial and Industrial (C&I) streams, or as hazardous wastes.

In the present scenario where sustainability is the focus, C&D waste is being considered in the Life Cycle Analysis of a building. Cradle to Cradle process includes the reuse of demolished waste and thus reduces the Embodied Energy of a building, its impact on natural and built environment.

Grave Concern to Environment

The last century was a period of major innovations in building materials. There are currently about 100,000 types of materials, and most are not suited to recycling and reuse. The recent concern about the environmental and economic impacts caused by disposal of these materials has led several countries to draw up new laws and take other actions that would minimize these problems.

Much of the materials used in construction usually have a very short life cycle, from 50 to 100 years, that happens because the quality of materials used is not required. However, this situation is changing slowly. About 10 countries are starting to reuse existing buildings rather than demolish. In the Netherlands, for example, some systems have been developed to facilitate concrete disassembly and reuse of buildings. The main benefits of reuse, recycling or reducing the materials of the work are energy savings and decreased use of natural sources. Efforts are being made to make various countries use different systems for disassembly in construction. New industries are processing building components for reuse in new buildings, and this can result in the use of this practice on a large scale.

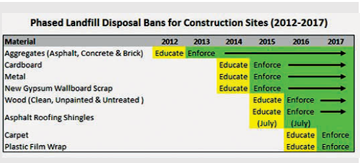

Governments worldwide have responded to the need to reduce waste with regulation and legislation that have framed a market for building materials and products derived from the construction and demolition (C&D) waste stream. There are now, more than ever, clear opportunities for business and industry to invest in activities that will create profit and improve environmental outcomes by extracting valuable resources from the C&D waste stream.

|

The built environment of the future is being constructed at the beginning of a new ecological era where governments are framing markets with regulation and legislation that respond to the challenges of environmental sustainability, and where industry must respond to the challenges of low-carbon economies and resource depletion. Businesses that are profiting and growing are adapting to these new challenges and responding with innovations that turn waste into valuable resources to supply the construction industry, which has traditionally been adverse to behavioural change.

Embodied Energy and Lifecycle Analysis of Construction Materials

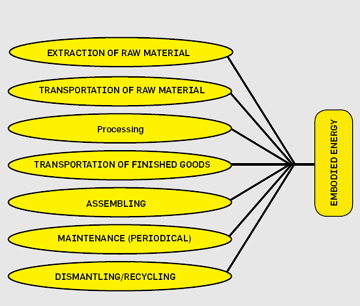

The embodied energy is the energy needed for production or manufacturing of a product which includes the power used in a process and used for the material and its transport infrastructure and production machines used in this production activity. One must be aware of the embodied energy expended throughout the life cycle of a building, which can vary from 30% to 50%. Reusing materials can greatly reduce the energy used to produce new materials that would be put in place the old.

Another very important factor is the analysis of the life cycle of the materials used, from material extraction to the final process of eliminating it, verifying the energy spends and available sources of materials, effects caused to health and human impacts on the environment. The life cycle of a product, focused on environmental design, characterized by its production stages, from extraction of raw materials to its final disposal, going from "cradle to grave." The analysis of the life cycle it is important to be able to assess the environmental impacts caused by this product and the definition of new strategies which aim to reduce these impacts. The concept that the life cycle of materials ranging from "cradle to grave" has changed a lot, because today we can say that this succession of steps that a material passes from the extraction process as raw material is from "cradle to cradle", the materials have been recycled, reused or manufactured, and restart the cycle.

Different types C&D wastes

C&D waste comprises of concrete, plaster, bricks, metal, wood, plastics etc. It is estimated that the construction industry in India generates about 10-12 million tons of waste annually. There is a huge demand of aggregates in the housing and road sectors but there is significant gap in demand and supply, which can be reduced by recycling construction and demolition waste to certain specifications. While some of the items like bricks, tiles, wood, metal etc. are re-used and recycled, concrete and masonry, constituting about 50% of the C&D waste is not currently recycled in India. The fine dust like material (fines) from C&D waste is presently not being used and thus wasted.

When considering a reusable and recyclable material, three major areas need to be taken into account are: economy, compatibility with other materials and material properties.

Stone: Stone can be reused for plinth formation, masonry construction, landscape purpose, ledges, platforms, window sills, coping etc. depending upon the form of available stones.

|

Concrete: Concrete is primarily a composition of cement, coarse aggregates, fine aggregates and water, further processed by addition of industrial products/ by products for enhancing the properties. Engineers are mainly dependent on nature for obtaining the Coarse and Fine aggregates as well as water for the chemical reaction with cement. Scarcity is there for all these naturally occurring materials and need is there to explore alternative sources. Even for the water with required properties, shift is towards the use of waste water after due treatment. One of the alternative sources of coarse aggregates is recycled concrete aggregates (RCA) which are obtained from the processed Construction and Demolition (C&D) waste. During and after the demolition of any concrete structure, the demolished concrete waste is taken to a recycling plant and there crushed into the required sizes which is called the Recycled concrete aggregate (RCA).

Sometimes, good sized precast element are also obtained during the demolition, which have a potential of being reused or otherwise, these are also crushed and converted into the recycled aggregates. Thus, use of recycled aggregates can be there with different quantum of their share by suitable replacing the component of naturally occurring aggregates. It will help out not only in meeting the situation where there is acute shortage of natural resources, but also a step towards the sustainability.

|

Timber: The waste timber is not only produced from the demolition of the building, but also from construction of wooden building wherein lot of timber waste is generated. Each source has its own system of recycling and reuse of recovered timber from the demolition of a building or the construction of a building. Whenever a building is decided to be dismantled, timber products like doors and windows are the items which are removed as first step and that too in original form. Timber products have a quality of a long service life which is much longer than the life of the building itself. Hence, in general such products unless eaten by the termites or damaged due to fire do not lose the Engineering properties for a long time and can be used multiple times and thus an environmentally friendly product. Timber used for recycling has to be free from any other demolition products like concrete, mortar, aggregates, sand, bricks, plastic, metals, tiles etc. Wood chips are produced from good quality wooden waste such as large size lumbers. Some of the particleboard producing companies and the pulp and paper producing companies are still using the recycled chip for their products. Chipped or shredded wood is also used as a sewage sludge bulking medium and other products lime pallets.

Bricks: Bricks are largely treated as waste when broken or damaged from the brick production line or from construction site due to poor internal handling and excessive cutting. Brick is a maintenance-free component of the structure which is durable during the complete service life of the building. The high durability property of the brick makes it environmental friendly in the sense that after the demolition of the structure, it can be reused repeatedly and the left over volume which is non-reusable can be recycled for other beneficial purposes. Generally, a building is not required to be demolished due to deterioration in the Engineering properties of the bricks.

Recovered bricks can be used like a fresh lot of bricks without any further processing. These can also be laid on as brick pavers or for landscaping or any other artistic creations. Brick paved streets are aesthetically pleasing and rain water also percolates through the pavement. Also, a brick surface is cooler in hot months. These street advantages make bricks a good choice in driveways. Bricks on edge are also sometimes used as economical pavement solutions in smaller compounds. Bricks from demolition sites can be recycled as Road base and construction fill and also as light weight concrete. Construction debris consisting of bricks can be recycled into brick aggregate through screening, crushing, re-screening and blending, which can then be used as pavement base material by proper mix proportions with cement and fly ash. Brick waste which are not suitable for recycling into the pavement base materials can be used in construction/land fill. Concrete prepared from crushed brick aggregate has good engineering and also better thermal properties but has greater shrinkage than ordinary concrete. Sometimes, during the manufacturing of bricks, due inadequate burning, or sometimes due to over burning, whole lot is turned into the production waste.

Tiles: Generally, it is difficult to extract tiles from the walls in proper shape and size in order to find them suitable for reuse. It also depends upon the type of the tiles, their life span and the existing conditions. Still tiles extracted from walls, even if these are broken pieces, provide an excellent opportunity to the artists /designers for making murals or other decorative master pieces. Broken tiles can also be used aggregate after crushing. If the tiles can be extracted or removed from the wall in good shape and size, these are reused for the same purpose after the removal stuck up mortar and then glued with suitable adhesives available in market today. Creative items like artifacts, table tops, special effects in drive ways, pedestrian subways etc. can be smartly created by reusing for a wide variety of projects.

|

Gypsum: In India, about 6 MT of waste gypsum such as phosphor-gypsum, fluro-gypsum etc., are being generated annually. Plaster developed from this waste gypsum has showed improved engineering properties without any harmful effect. Phosphor-gypsum and lime sludge can be recycled for manufacture of Portland cement, masonry cement, sand lime bricks, partition walls, flooring tiles, blocks, gypsum plaster, fibrous gypsum boards, and supersulphate cement.

Metals & metal alloys- Ferrous Metals are the most profitable and recyclable material. In India more than 80% scrap arising is recycled. Scrap steel is almost totally recycled and allowed repeated recycling. Structural steel can be reused as well as 100% steel can be recycled to avoid wastage at construction site. The main non ferrous metal collected from construction and demolition sites are aluminum, copper, lead and zinc . In India aluminum usage is up to 95000 tonnes with about 70% recycled in 2004. Copper is recycled up to 119000 tonnes out of a national market of 262000 tonnes.

Debris: Construction debris can be recycled to manufacture paver blocks which can be used in light traffic areas and masonry blocks. Other uses of processed debris include use in lean concrete for leveling purpose, as mortar for masonry, as bedding mortar for pavement tiles and used for land filling.Market rates processed debris products cost 32% less than new construction material and the strength of these materials is comparable with new materials. Market potential on an average in Pune city estimates about 40 crores of bricks in a year.

Composite materials: The plastic wastes are best for recycling if these materials are collected separately and cleaned. Recycling is difficult if plastic wastes are mixed with other plastics or contaminants. Plastic may be recycled and used in products specifically designed for the utilization of recycled plastic, such as street furniture, roof and floor, PVC window noise barrier, cable ducting, panel. Japan practices adopted burning of waste plastic at high temperature and turning them in to ultra fine particles, known as man-made soil. The third largest consumer of composite materials is construction sector, automobile and aeronautics being first two largest consumers. Composite materials like thermoplastics are not only using non-renewable resources, they are non-biodegradable products. Thermoplastics (Polycarbonate, polyethylene, polypropylene, PVC etc.) can be recycled, but recycling involves high costs, whereas thermosets (Epoxy adhesives) are difficult to recycle. The lack of adequate markets, high recycling cost, and lower quality of the recyclates are the major commercialization barriers in recycling of composite materials. PVC-U sourced mostly from window and door fabricators is being recycled into wiring accessories and cable management systems including skirting and trunking. Composite materials can be down-cycled.

Indian scenario

With the increasing demand for built spaces and scarcity of land, a trend of redevelopment projects is coming up. C&D waste management in India is subject of concern in the construction market. C&D waste generation is about a one third of the total municipal solid waste generated in India. Infrastructure sector (construction and repair of roads, bridges, flyovers etc.), real estate (especially redevelopment and renovation work), demolitions of unauthorized structures etc. are sources of bulk generation of waste. This emphasizes the need of C& D waste management in India. Construction and waste management through reuse, recycle, deconstruction is being practiced abroad in countries like U.K., USA, France, Denmark, Germany and Japan. According to a study commissioned by Technology Information, Forecasting and Assessment Council (TIFAC), 70% of the construction industry is not aware of recycling techniques.

Asian institute of technology, Thailand had conducted a survey recently in various Asian countries and published a report on reduce, reuse and recycle (3R) practices in construction and demolition waste management in Asia. The study included the countries like Bhutan, Japan, Hong Kong SAR, PR Chin, Thailand and others including India. The study reveals the current status on C & D waste management in terms of Technologies relative to 3R and Information base regarding C & D waste is poor in India, whereas reusing facilities and recycling facilities have moderate existence and management practices, technologies, stakeholder's participation in C & D Management is relatively low and the status of sorting/ segregation, storage and monitoring facilities is unknown.

The cost of construction materials is increasing enormously. In India, the cost of cement during 1995 was Rs. 125/kg and in 2012 the price increased to Rs. 330/bag. In case of bricks the price was Rs. 0.66 per brick in 1995 and the present rate is Rs. 6 per brick in 2012. With the environmental hazards caused by excessive and illegal extraction of river sand, the mining of river sand is banned since April 1, 2012. The raw materials used in construction are largely non renewable natural resources hence meticulous use of these materials is essential. The demand for aggregates in 2007 has seen an increase by five percent, to over 21 billion tones, the largest being in developing countries like China, India, etc.

The presence of C&D waste and other inert matters is significant (almost one third of total MSW on an average) but so far, no notable development has taken place for utilizing this in an organized manner. At present, private contractors remove this waste to privately own low-lying land for a price or more commonly, dump it in an unauthorized manner along roads or other public land. Small quantities of construction and demolition waste usually get mixed with domestic waste due to lack of segregated storage and collection facilities.

Government initiatives and regulations

With the global concern of conservation of energy and natural resources, there is urgent need of implementing C & D waste management strategies through technological and design solutions of adoptability, deconstruction, recycling and reusing and effective formation of legislative, administrative and monitoring framework for implementation of the same. Development of human resources for implementation of C & D waste management through awareness and training is another important concern. R&D work towards exploring newer applications and maximizing use of existing technologies for a sustainable C & D waste management is need of a time.

India has provisions for the protection and improvement of the environment in its constitution. The Department of Environment and several enforcement agencies like Central Pollution Control Board (CPCB) were already given statutory authorities, by then. Environmental considerations have been integrated into making at all levels and the National Environment Policy of 2006, which incorporates the concept of the 3Rs, is the latest attempt in this direction. Major strategies and activities include:

- mandatory requirement of Environmental Statement (Form V)

- the Charter on Corporate Responsibility for Environment Protection (CREP) ,through which stakeholders commit to participatory action beyond mandatory levels

- a registration scheme in which recyclable waste is channeled only to entities which can process it in an environmentally sound manner

- promotion of cleaner technologies and waste minimization circle concept

|

The Solid Waste Management in India is covered under various regulations. It is covered through various national as well as some state level regulations. Some guidelines are also prescribed by Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCB). Ministry of Environment and Forests notified the Municipal Solid Waste (Management and Handling) Rules, in 2000 which is applicable to every municipal authority and hold it responsible for collection, segregation, storage, transportation, processing and disposal of municipal solid wastes and as also to upgrade existing facilities to arrest contamination of soil and ground water. According to MSWM rules 2000, it is the responsibility of generator, to avoid littering and ensuring delivery of waste. Specific regulations for the recent waste streams such as Electronic waste (E-waste) and C &D waste have not yet been formulated.

C&D waste requires focus primarily in view of:

- It's potential to save natural resources (stone, river sand, soil etc.)

- It's bulk, which is carried for long distances without any proportionate return

- The space it occupies at the sanitary landfill site unless the fines are used as landfill cover

- It's potential for spoiling processing of biodegradable as well as other recyclable waste.

On the other hand it has potential use after processing and grading. Thus, its presence in terms of quantity as well as its importance is growing. So far in India there is very little effort to manage and utilize construction and demolition waste.

For instance, Maharashtra has taken a pioneering step and notified the Maharashtra Non-Biodegradable Solid Waste (Proper Scientific Collection, Sorting and Disposal in Areas of the Municipal Corporation) Rules, 2006, wherein reuse of this waste is included in the action plan. The Action Plan, inter alia, prescribes separate collection and disposal of debris and bulk waste. Each city needs to have its own mechanism for collection and disposal of waste from bulk waste producers and construction debris. Municipal Corporation of Greater Mumbai notified the „Construction, Demolition and De-silting waste (Management and Disposal) Rules?. The Municipal Corporation of Delhi has carried out a feasibility study on use of C&D waste in road and embankment construction.

Sustainability of C&D waste management is the most crucial issue. Until the relevant standards are stipulated and market is developed for C&D waste recycled products, financial sustainability cannot be achieved. Therefore it would be necessary to evolve a system in which the generator of the C&D waste – whether small or large – pays for appropriate disposal. The ULB may have to share some of the cost, particularly for the small generators from slum areas, whose affordability level may be low and is otherwise difficult to track. At a later date when the use of recycled C&D waste is mandated through regulatory measures and market for processed C&D waste developed, the pattern of cost sharing may be changed. This mechanism should have the flexibility to incorporate changes depending upon any revenue accrual from sale of recycled C&D waste in future.

Not much effort has been made in this sector and data on generation and characteristics is scarcely available. Policy mandate would be required for:

- generating authentic data by each ULB followed by collation of data by the Nodal Agency in each state,

- expert organizations should be involved in analysis of data, of material and various situations and options and

- setting up pilot demonstration facility preferably in each state. Data collection by the ULBs would serve two purposes including generation of data in a cost effective manner and sensitization of the ULBs, the prime actors in waste management.

India's First Recycling Facility in New Delhi

At present, in India, the recycling of Construction and Demolition waste has started now only and we have to go a long way in this direction. In collaboration with Municipal Corporation of Delhi (MCD), IL&FS Environmental Infrastructure & Services ltd (IEISL) has developed a pilot project to demonstrate the potential benefits of increasing the recycling rates for C&D waste in Delhi. The project itself has been set up on a Public Private Partnership (PPP) basis, which has proved successful as it serves the dual purpose of saving landfill space on the one hand and also developing the market for C&D recyclables. The facility is located in Burari on approximately seven acres of low and marshy land which has provided by the MCD for a period of 10 years.

In the processing facility, IEISL collects some 500 tonnes per day of C&D waste from three designated zones in Delhi - Karol Bagh, Sadar- Paharganj and City. The C&D waste is recycled into aggregates at the waste management facility and in turn converted to Ready Mix Concrete (RMC), pavement blocks, kerb stones, and concrete bricks. So far IESL has collected approximately 450,000 tonnes of C&D waste over a period of 22 months.

A 175 metre long road connects the gate to the main road south of the plant. Internal peripheral tracks developed to facilitate the sustained movement of loaded vehicles to the weighbridge in all weather conditions, and further to the unloading areas followed by their exit to the main road. The buildings conform to the IS code standards. IEISL operates and maintains an optimum number of vehicles in accordance with the prevailing demand for collection and transportation services within the designated areas. The vehicles are equipped with GPS system to track their movement on a continuous basis. A single shift running from 9pm to 6am is used for the movement of waste from designated areas to the plant. The average load carrying capacity of a double axel tipper truck is 15 tonnes and that of a single axle tipper truck is nine tonnes. Seven single axle and five double axel tipper trucks are currently being used. Each tipper truck makes four trips per shift where one round trip is approximately 40 km. The plant is designed to work in two shifts i.e. 16 hours a day, operating 330 days in a year. An MCD representative is present at the time of loading the C&D waste and a digital weighbridge weighs the tonnage of waste received at the plant. Further to this, a video surveillance system has been installed at the plant and both real time and recorded footage can be accessed and viewed. The 30 tonne capacity weighbridge is used to maintain an electronic database of the details of each consignment received at the site.

|

Processed C&D waste is used for sub base of roads and for making bricks, paver blocks & kerb stones. The capacity of the plant is 500 T per day. There are designated collection points where containers and skips are placed as a first storage point of C&D waste where the waste is brought in by private persons. As an additional measure, sufficient vehicles are also in operation to collect the waste from various locations of the city as per the services required from pick up points. In 2012, 153000 T of C&D waste has been processed for making useful products. Out of this 11700 T of aggregates,

5632 T of Granular sub-base and 4289 T of sand has been produced. Further, 2000 cum of cast products and 6000 Cum of Ready Mix Concrete has been produced in this plant in 2012. Fig. 4 shows the Pavement Blocks and Kerb stones being produced at Burari Plant.

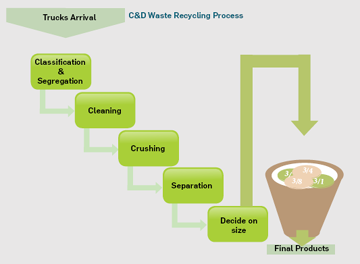

C&D Waste Recycling Process

According to the report published by Asian institute of technology, school of environment, resources and development, Thailand, reusing facilities and recycling facilities in India have moderate existence, whereas the status of sorting/ segregation, storage and monitoring facilities is unknown. There are three types of recycling plants Viz. Mobile, Semi-Mobile and Stationary plant. In the Mobile plant, the material is crushed and screened and ferrous impurities are separated through magnetic separation. The plant is transported to the demolition site itself and is suited to process only non-contaminated concrete or masonry waste.

|

In the semi-mobile plant, removal of contaminants is carried out by hand and the end product is also screened. Magnetic separation for removal of ferrous material is carried out. End product quality is better than that of a Mobile unit. These plants are not capable to process a source of mixed demolition waste containing foreign matter like metal, wood, plastic, hardbound etc. Stationary plants are equipped for carrying out crushing, screening as well as purification to separate the contaminants. Issues necessary to be considered for erection of a Stationary plant are: plant location, road infrastructure, availability of land space, provision of weigh-bridge, provision for storage area etc. Different types of sorting devices and screens are used for separating contaminants from end-product and grading the recycled product in various grain sizes. Vibrating screens, star screens or disc-separators are used for removal of impurities.

|

A fixed recycling plant requires higher volumes of demolition waste to justify high investment in complex, screening and separation systems, which are necessary to process mixed demolition waste. It has to be located in a place, where large volume of waste is available and the market for recycled product is close by. Unless the market for recycled aggregate is developed, economic viability of such a unit would be questionable. Looking at the capital investments involved in equipments and facilities required for recycling the materials, R & D shall be done on modifications of existing equipments like jaw crusher and impact crusher prevailing in India to suit the requirements of recycling and processing of building materials.

Challenges Involved

For recycling to be attractive from the point of the waste generator, it is necessary to have competitive cost and also provide other advantages. Transport, waste disposal and environmental fines are some factors that should be taken into account when assessing the economic viability of recycling. One must evaluate the waste according to their physicochemical characteristics, durability, performance, suitability for the user and others, always having the best possible use, if necessary, for this, the involvement of a multidisciplinary team.

India counters few challenges in C&D waste management including:

- Unawareness about use of recycled materials.

- Less confidence among users about quality of recycled materials

- Unavailability of platform or market available for recycled materials.

- No provisions for quality standards for recyclable materials in National Building Codes and Bureau of Indian Standards.

Potential of use of these materials for high rise buildings and long span structures yet to be studied especially in case of recycled concrete. There are some problems to be faced in the implementation of this process: there are no many tools available for disassembly, the cost of land for disposal of construction waste is low, the disassembly process is long and the environmental and economic benefits still were not well established and old buildings and their components were not prepared for this process.

Should also evaluate the risk that a recycled material can cause on the health of workers at a recycling industry and users, because that may contain hazardous materials such as heavy metals, and volatile organic compounds and, in case of recycling, they can lose the guarantee of detention. Therefore, it is necessary that the choice of recycling be very careful about the consumption of raw materials and of energy through the recycling process. The recycling of residues of construction may cause damage to the environment, depending on the amount of materials and energy needed to process.

The type of waste and the use of the method of recycling technology employed, may involve risks, since these residues are often made of hazardous elements. The lack of adequate technology for the treatment of the residue, lack of place to dispose of it after be used and the cost of the recycling process must also be studied in order to do a correct choice of the recycling process to be executed.

The choice of material in the project design based on the concern of the use of appropriate materials is crucial to reducing environmental impacts. For this to occur, should take place some factors, such as reducing the type of material to be used, durability and design flexibility, the flexibility of design, flexibility of connections, independence of layers of buildings, information and IDs of accessible materials, among others.

Stakeholders

There should be a proper institutional mechanism to take care of the collection, transportation, intermediate storage (if necessary), utilization and disposal of the construction and demolition waste. During the interaction with municipal officials from various departments, it was revealed that the Sanitary Department, the Health Department, Engineering or the Planning Department, solid waste management department are responsible for construction and demolition waste in different situations. For example, if debris is disposed into river bed, irrigation department will take action against the concern builder/owner and remove the debris from river bed. Under such circumstances, it is extremely important that either the Solid Waste Management Department is made responsible for all the activities related with C & D waste, since non-co-ordination among various departments being one of the major reasons for ineffective infrastructure management in India. It is essential that proper accountability is fixed and official information is readily available regarding day to day situation. Private- public participation may resolve the issue regarding collection, transportation and disposal of C & D waste effectively, since accountability, optimum use of resources, availability of funds and skilled personnel being the assets of private sectors.

|

The key players in the sector of C&D waste management policies are local authorities, developers/builders, contractors, owners, NGOs, research institutes, academic institutes, professionals like architects and engineers etc. According to the report published by Asian institute of technology on reduce, reuse and recycle (3r) practices in construction and demolition waste management in Asia, participation of national and local authority is moderate, participation of contractors and NGOs is relatively low whereas participation of clients, consultants and associations is unknown.

Responsibilities of Key Stakeholders

Responsibility of Municipal Authorities

- Providing and developing infrastructure for collection, storage, segregation, transportation, recycling, processing and disposal of C & D waste.

- Complying with the MSW rules as per the implementation schedule laid down in legislation.

- Proper co-ordination among various departments of authority.

- Conducting Training programmes regarding C & D waste for the officials of concerned departments.

- Improvement of existing land filling sites, if any.

- Identification of landfill sites for future use

Responsibility of The Generator Of Waste

- Avoidance of littering and ensuring delivery of wastes as stipulated by the municipal authority.

- Complying with the MSW rules/ C & D waste rules.

- Insisting on designs and technologies which will reduce the waste and reduce the use of materials in construction.

Responsibility the State Pollution Control Board (SPCB)

- Monitoring the compliance of the standards regarding ground water, ambient air, leachate quality and the compost quality including incineration standards as specified under Schedules II, III and IV4. The details of application procedure, grant of authorization for setting up waste processing and disposal facility including landfills are also given in the Rules.

- Co-coordinating with CPCB and the Committees with particular reference to implementation and review of standards and guidelines and compilation of monitoring data. Most of compliance monitoring and enforcement is done by SPCBs. The few direct enforcement actions taken by the CPCB are generally done by the zonal offices.

Responsibility of Architects, Engineers, Property Owners and Developers

- Designing for adaptability(less function specific), deconstruction and dismantling

- Use of modular co-ordination with pre-fabricated components, use standard accepted technologies

- Designing building for parallel disassembly rather than sequential disassembly (time saving, material saving, labour cost saving)

- Specify materials and assemblies that can be easily disassembled at the end of their useful life.

- Choosing durable non-toxic interior finishes or materials.

- Surveying the site before demolition or deconstruction.

- Identifying salvage and reuse items, recyclable materials and hazardous materials for special handling.

- Developing a Construction Waste Management Plan.

- Selecting a contractor with proven waste reduction experience.

- Establishing requirements for waste reduction. Beginning with making waste reduction a priority from the start of the project and planning for it throughout all phases of design, construction, installation, and occupancy.

- Setting goals for waste reduction for each project and preparing a team of qualified professionals experienced in environmentally sound design and construction practices.

- Training own or hiring a deconstruction crew.

- Planning for recyclable materials

- Investigating removal and separation techniques.

- Selecting material with high resale value.

- Planning for collection procedures and allocate space on site.

- Estimating the costs and savings.

Conclusion

Effective recycling and reusing of waste building materials reduces the need for new materials, reduces materials to be disposed in the MSW landfill, transportation cost of disposal and creates a cleaner and safer project site. It also avoids mixing of C & D waste with bio-degradable waste and avoids nuisance of its potential for spoiling processing of biodegradable as well as other recyclable waste. Most importantly, C & D waste management reduces dependence on natural resources such as trees, oil, and minerals plus creates less pollution by reducing manufacturing and transportation related emissions. Reduction of the energy and water required to produce building materials from virgin materials contributes to reduced greenhouse gasses related to the manufacturing and transportation of those materials. Thus, the environmental impact of the project can be reduced. Segregation of C & D waste at source increases the efficiency of waste materials for reuse and recycle and increases salvage value of the same.

Construction management techniques also help developer/owner to earn points towards qualifying for LEED (India) and TERI GRIHA rating systems prevailing in India. It also helps the developer to promote and sale their project in the market. Deconstruction and Segregation of waste are labor intensive activities. This will generate employment opportunities in India.The manufacturing of recycled content materials further increases job opportunities. Market of reusable materials, salvageable materials will cut down the project cost for developers on one hand and on the other hand, it will give opportunities to poor section of the society to build their own houses by purchasing these materials at discounted rate from resale markets.

Box Item: Recommendations

With given a situation of scale of these projects and material inputs that it requires, there is huge challenge to manage C & D waste in near future.

- Data should be generated on C&D Waste generation and its characteristics.

- Separation of C&D waste should be promoted at source and an institutional mechanism for waste collection should be established involving the informal sector who can be trained to separate the waste into categories and also do some amount of use, reuse and reprocessing like making tiles from crushed construction debris.

- Charges should be levied on C&D waste generators.

- Environmentally friendly technologies should be adopted for waste utilization of C&D.

- Standards for C&D should be formulated for waste utilization.

- Technical and institutional support should be made available for good data analysis and for evolving ways for use of C&D waste.

- Policy support, guidelines and regulatory arrangement should be made.

- Amendment should be made to the existing MSWM Rules 2000 to include and address the C&D waste with guidelines for its collection, utilization and safe disposal.

- Fiscal incentives shall be given to the builders/developers, owners of building using reusable, recyclable and recycled content materials and construction technologies.

- Charges shall be levied on the disposal of C & D waste to the designated landfill sites based on amount of waste generation.

- BIS and NBC shall include provisions for quality standards of reusable, recyclable and recycled content building materials and construction technologies.

- MSW department shall be made accountable for all the activities related to C & D waste management to reduce the confusion among various departments regarding accountability.

- Awareness campaigns and training shall be conducted regarding C & D waste management for all the stakeholders. Academic and Research institutes, NGOs, Government departments, print and electronic media, Construction sector can contribute towards this aspect.

- Fiscal incentives shall be given to the builders/developers, owners of building using reusable, recyclable and recycled content materials and construction technologies.

- Charges shall be levied on the disposal of C & D waste to the designated landfill sites based on amount of waste generation.

- BIS and NBC shall include provisions for quality standards of reusable, recyclable and recycled content building materials and construction technologies.

- MSW department shall be made accountable for all the activities related to C & D waste management to reduce the confusion among various departments regarding accountability.

- Awareness campaigns and training shall be conducted regarding C & D waste management for all the stakeholders. Academic and Research institutes, NGOs, Government departments, print and electronic media, Construction sector can contribute towards this aspect.

- Data shall be generated regarding generation of C & D waste, availability of materials according to categorization of materials as reusable, recyclable and recycle content materials, their quality standards and suggested application in future.

- There shall be easy access to the information regarding C & D waste generation, legislative and regulatory frame work and procedures to all the stakeholders and common public.

- Awareness and promotion of Green Rating Systems shall be geared up since these rating systems include credit points for C & D waste management.

References: