High Strength Concrete

What is High Strength Concrete?

It is a type of high performance concrete generally with a specified compressive strength of 40 MPa or greater. The compressive strength is measured on 150,300 mm OR 100, 200 mm test cylinders generally at 56 or 90-days or some other specified age depending upon the application. The production of high strength concrete requires more research and more attention to quality control than conventional concrete.

Why Do We Need High Strength Concrete?

- To put the concrete into service at much earlier age, for example opening the pavement at 3-days.

- To build high-rise buildings by reducing column sizes and increasing available space.

- To build the superstructures of long-span bridges and to enhance the durability of bridge decks.

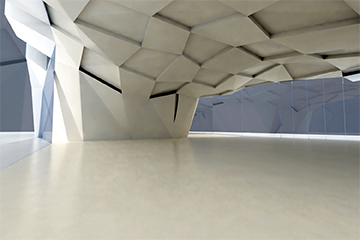

- To satisfy the specific needs of special applications such as durability, modulus of elasticity, and flexural strength. Some of these applications include dams, grandstand roofs, marine foundations, parking garages, and heavy duty industrial floors. (Note that high strength concrete does not guarantee durable concrete.)

How to Design High-Strength Concrete Mixture?

Optimum concrete mixture design results from selecting locally available materials that make the fresh concrete place-able and finish-able and that ensure the strength development and other desired properties of hardened concrete as specified by the designer. Some of the basic concepts that need to be understood for high strength concrete are:

|

- Aggregates should be strong and durable. They need not necessarily be hard and of high strength but need to be compatible, in terms of stiffness and strength, with the cement paste. Generally smaller maximum size coarse aggregate is used for higher strength concretes. The sand may have to be coarser than that permitted by ASTM C 33 (fineness modulus greater that 3.2) because of the high fines content from the cementitious materials.

- High strength concrete mixtures will have a high cementitious materials content that increases the heat of hydration and possibly higher shrinkage leading to the potential for cracking. Most mixtures contain one or more supplementary cementitious materials such as fly ash (Class C or F), ground granulated blast furnace slag, silica fume, metakaolin or natural pozzolanic materials.

- High strength concrete mixtures generally need to have a low water-cementitious materials ratio (w/cm). W/cm ratios can be in the range of 0.23 to 0.35. These low w/cm ratios are only attainable with quite large doses of high range water reducing admixtures (or superplasticizers) conforming to Type F or G by ASTM C 494. A Type A water reducer may be used in combination.

- The total cementitious material content will be typically around 415 kg/m3 but not more than about 650 kg/m3

- The use of air entrainment in high strength concrete will greatly reduce the strength potential. More attention and evaluation will be necessary if the job specification sets limits for other concrete properties such as creep, shrinkage, and modulus of elasticity. The engineer may set limits on these properties for the design of the structure. Current research may not provide the required guidance for empirical relationships of these properties from traditional tests and some of these tests are quite specialized and expensive to conduct for mixture evaluation. From theoretical considerations, lower creep and shrinkage, and high modulus of elasticity can be achieved with higher aggregate and lower paste volumes in the concrete. Using the largest size aggregate possible and medium to coarsely graded fine aggregate can attain this. Smaller maximum size aggregate such as 9.5mm can be used to produce very high compressive strength but required properties like creep, shrinkage, and modulus of elasticity may be sacrificed. If difficulty is encountered in achieving high strength, simply adding more cementitious material may not increase strength. Factors such as deleterious materials in aggregates, aggregate coatings, coarse aggregate fracture faces, shape and texture, and testing limitations may prevent higher strength from being achieved. Final concrete mixture proportions are determined by trial batches either in the laboratory or by small size field production batches. The production, transportation, placement and finishing of high-strength concrete can differ significantly from procedures used for conventional concrete. For critical projects it is highly recommended that a trial pourand evaluation be conducted and included as a pay item in the contract. Pre bid and pre-construction

|

meetings are very important to ensure the success of projects using high strength concrete. During construction, extra measures should be taken to protect against plastic shrinkage and thermal cracking in thicker sections. High strength concrete may need longer time before formwork is removed.

High strength concrete test cylinders should be carefully molded, cured, capped, and tested. Extra care and attention to handling of test cylinder specimens at very early age is necessary. Slower setting time of high strength concretes may be experienced. The ASTM Standards are continuously being revised to account for additional special precautions needed when testing high strength concrete. Particular attention should be paid to the type of mold, curing, type of cylinder capping material, and characteristics and load capacity of the testing machine.

|

How to design a good Roller Compacted Concrete Mix?

Selection of proper materials and correct proportioning is critical to the production of quality Roller Compacted Concrete mixtures. The mixture design process should not use a trial and error approach, but rather a scientific and systematic approach that takes into account the desired engineering properties, construction requirements, and economics.

A number of mixture proportioning methods have been successfully used throughout the world for Roller Compacted Concrete structures; therefore, it is difficult to identify one procedure as the standard procedure. However, the most common mixture proportioning methods are variations of the following two general approaches:

- Concrete Consistency or workability method: A w/cm approach, with the consistency kept constant and the mixture determined by absolute volume

- Soil Compaction method: A cement-aggregate approach, with the mixture determined by optimum moisture content and maximum dry density

- Whichever method is used, the goal is to produce a Roller Compacted Concrete mixture that:

- Has sufficient paste volume to coat the aggregates and fill the voids between them;

- Is able to produce the required mechanical strength and elastic properties;

- Has workability characteristics that make it easy to achieve required density; and

- Is durable enough to endure in the given environment.

Concrete Consistency Method

The concrete consistency method normally requires the establishment of specific mixture parameters such as the amount of aggregates, the amount of water, or the amount of cementitious materials. One of these parameters is then adjusted in order to meet a required level of consistency, often measured using an apparatus called a Vebe consistometer. The consistency is measured as the time required for a given mass of concrete to be consolidated by external vibration in the Vebe apparatus cylindrical mold. This method has been used primarily for hydraulic structures.

Soil Compaction Method

The soil compaction method is the most widely used mixture proportioning method for Roller Compacted Concrete pavements. This proportioning method involves establishing a relationship between the density and moisture content of an Roller Compacted Concrete mixture to obtain the maximum density by compacting samples over a range of moisture contents.

The soil compaction method consists of the following steps:

1. Choose well-graded aggregates

The gradation of the combined aggregates should approach a maximum-density grading. The 0.45 Power curve is one method that can be used to define a dense gradation approaching the maximum density of any maximum size of aggregates.

Generally, a gradation falling within the suggested band is desired to produce a product that can be compacted to near maximum density of the blended aggregates. It should be noted that the suggested band with a 3/4 in. (19mm) nominal maximum size provides gradation limits approaching the 0.45 Power curve for 3/4 in. (19 mm) maximum size. The 0.45 Power curve falls near the center of the band except for particles smaller than No.100 sieve.

2. Select a mid-range cementitious content

Choice of cementitious materials is based on the project specifications, economic considerations, availability of materials, and production considerations. For wearing course applications, a good starting point may be between 11 and 13 percent cement without the addition of CMs. The cementitious materials are expressed as a percent of total dry materials. It is equal to the weight of cementitious materials divided by the total weight of cementitious materials plus weight of oven-dried aggregates, and the result is multiplied by 100.

Weight of Cementitious Materials / Weight of Cementitious Materials + Oven Dried Aggregates x 100

3. Develop moisture-density relationship plots

For a fixed cementitious materials percentage, different moisture contents are selected to develop a moisture-density plot. The percent moisture content is equal to the weight of water divided by the total weight of cementitious materials plus weight of oven-dried aggregates, and the ratio is multiplied by 100.

Weight of Water / Weight of Cementitious Materials + Oven Dried Aggregates x 100

For most aggregates, the optimum moisture content is found to be within the range of 5 to 8 percent. It is suggested that the moisture content be varied within this range.

4. Cast samples to measure compressive strength

For each cementitious content, compressive strength specimens are made using the vibrating hammer (ASTM C1435) or the vibrating table method (ASTM C1176). All specimens should be molded at the optimum moisture content corresponding to the cementitious content of the mix.

5. Test specimens and select required cementitious content

The specimens are tested to determine the compressive strength at the selected cementitious contents. The data are plotted and a compressive strength versus cementitious content curve is developed, as shown here. From the curve, a cementitious content can be selected to meet the required strength. The required strength, f 'cr, should be equal to the specified strength, f 'c, plus a strength safety factor.

6. Calculate mixture proportions

After final selection of the cementitious content and optimum moisture content, the final mix proportions can be calculated for the project. Saturated surface-dry (SSD) condition of the aggregates should be used when determining the weight and corresponding volume calculations.

If the required cementitious content is significantly different from all cementitious contents used during testing, another moisture-density relationship test may be needed to determine the optimum moisture content at the required cementitious content. It is also reasonable to estimate this optimum moisture content by interpolation if the percent optimum moisture content did not vary significantly over the cementitious content range used during testing.

Reference

1. State-of-the-Art Report on High Strength Concrete, ACI 363R, ACI International, Farmington Hills, MI, http://www.aci-int.org.

2. Guide to Quality Control and Testing of High Strength Concrete, ACI 363.2R, ACI International Farmington Hills, MI.

3. Creating a balanced mix design for high strength concrete, Bryce Simons, The Concrete Producer, October 1995, http://www.worldofconcrete.com

4. Getting Started with High-strength Concrete, Ron Burg, The Concrete Producer, and November 1993.

5. Effects of Testing Variables on the Measured Compressive Strength of High Strength (90 MPa) Concrete , Nick J. Carino, et al., NISTIR 5405, October 1994, National Institute of Standards and Technology, Gaithesburg, MD, http://www.nist.gov.

6. 10,000 psi Concrete , James E. Cook, ACI Concrete International, October 1989, ACI International, Farmington Hills, MI

Acknowledgement: www.nrmca.org/aboutconcrete