Hot and Cold Weather Concreting

Introduction

Concrete buildings and other structures are built in most countries around the world and in some regions the climates are typified by prolonged spells of either hot or cold weather. Ready mix concrete and construction companies in these regions manage to produce good-quality concrete despite these climatic drawbacks. In many regions with adverse climates there are consensus specifications and guidance documents for concrete production which give details of methods which can be used to combat the adverse conditions.

In the more temperate parts of the world, cool, humid weather is the norm. In these locations, although prolonged hot or cold spells are not unusual, it usually comes as a surprise when they arrive and it may be too late to apply even the most rudimentary precautions to mitigate their undesirable consequences.

Physiological effects in both hot and cold conditions should not be ignored. Operatives and supervisors cannot be expected to produce good-quality concrete if they have been exposed to the elements for long periods without proper protection.

When the concreting process is being carried out, the air temperature by itself isn't the determining factor on whether you should pour concrete. The temperature of the air, the humidity level, and the wind speed, the temperatures of the surface where you are placing the concrete, the water and the dry concrete in the bag all play a huge part and must be taken into consideration. The air, wind and humidity are pretty much beyond your control but some of the others you can influence. It is important to remember that the temperature of the mixed material is as important as the air temperature.

Strength and durability of concrete is inversely proportional to the weather when concreting process is performed. Hence, construction personnel will need to take extra care or additional measures when it comes to concreting. In fact, some parts of the world remain hot throughout the year. These are situations when paying attention to a few simple yet very necessary points on hot weather concreting would certainly help in completing any concreting without compromising its quality. Sunlight leads to hot weather which compels us to adopt special measures while concreting which is known as hot weather concreting.

Hot Weather Concreting

Definitions

The definition of hot weather may vary from country to country. For Indian weather condition, Indian codes prescribe 400C as the threshold for hot weather concreting. That means, any concreting done at an ambient temperature of more than 400C can be regarded as hot weather concreting inviting special measures to be adopted.

|

| Hot Weather Concreting |

Apparently, that's not the case in many other parts of the globe due to different weather condition. For example, according to ACI 305, any combination of high ambient temperature, high wind, low relative humidity and solar radiation (sunlight) is a good enough pre-condition to label concreting as hot weather concreting. Some other views say that any temperature above a comfortable room temperature, say 250C or so, begins to make concrete bit uncomfortable i.e., concrete starts reacting differently and hence calls for special care befitting hot weather concreting, if strict quality is to be maintained.

Hydration Process

Therefore, it is very important to address how hot weather concreting is different from concreting in normal temperature. Concrete sets and gains strength due to hydration of cement within it. Hydration of cement occurs faster in hot weather. Hydration of cement also releases heat. Hence, faster the hydration of cement faster the heat generation. This makes the concrete hotter, further speeding up the process of cement hydration or setting. Fast setting cement does not allow concrete enough time to gain strength sufficiently. While the initial strength may not suffer, the long term strength (28-day strength) is adversely affected. This is the key reason why hot weather concreting needs special care. Otherwise, you would be playing with the designed strength of the concrete.

Water Demand

Water demand of a concrete mix is higher in hot weather due to rapid evaporation. Unless suitable measures are adopted, extra water would have to be added to the concrete mix in order to maintain the workability of the mix. This would increase the water cement ratio which in turn would decrease the strength of the concrete. If additional cement is added to keep the w/c ratio unchanged then cost would increase as cement is the costliest ingredient of a concrete mix.

Rapid drying of freshly poured concrete surfaces occurs in hot weather due to quicker evaporation or loss of water from the mix. If proper care is not taken, cracks known as plastic shrinkage cracks bound to appear, which are quite difficult to repair later on. Concrete surface tends to shrink quickly due to fast moisture loss while the mix is yet to develop sufficient strength to counter these shrinkage stresses resulting in the cracks. In hot weather, the concrete bed, forms, steel reinforcement, mixing or concreting equipments etc. too get hot transferring the heat to the mix contributing further to the problem.

Effects of Hot Weather on concrete

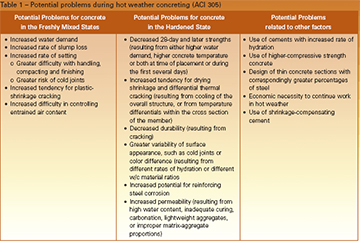

High temperatures can affect concrete at all stages of the production and placing process and most of the effects can have consequences for long-term strength or durability. Some of the problems resulting from high temperatures are listed in Table 1. They are a consequence of high temperature increasing the rate of the hydration reaction and the movement of moisture within and from the surface of concrete.

The combination of High ambient temperature, Low relative humidity and high wind velocity adversely affects the desirable properties of concrete e.g., strength, impermeability, dimensional stability, resistance to weathering, wear and chemical attack.

Setting time- As the concrete temperature increases, the setting time, and thus the time to place, compact and finish the concrete is reduced.

Workability and slump- Higher temperatures reduce the workability (or slump) of the concrete more rapidly with time. Adding more water to improve the workability of the mix decreases the strength and increases the permeability, and ultimately affects the durability of the concrete.

Durability

Many deterioration mechanisms depend on the passage of fluids or gasses through the concrete pore structure. Achieving a less 'permeable' concrete is one if the principal objectives when trying to obtain durability. The main means of doing this is to produce a concrete with low water/cement ratio. As noted above, high temperature affects both the initial workability and the rate at which workability is lost and hence there can be a temptation to add more water at the mixer or at site. This would lead directly to concrete which is more vulnerable to freeze-thaw, weathering, sulphate attack and the penetration of carbon dioxide and chloride solutions leading to reinforcement corrosion. The lower workability resulting from high temperature can lead to poor compaction which also leaves the concrete more vulnerable to deterioration. Plastic shrinkage or early thermal cracks can also lead to reduced durability as they may permit moisture, carbon dioxide, oxygen or chlorides to gain easy access to the concrete or reinforcement.

|

Compressive strength- Higher water demand and higher concrete temperature could lead to reduced 28-day strengths. If more water is added to the concrete mix at higher temperatures to maintain or restore workability, the water-cement ratio will be increased, resulting in a loss of both potential strength and durability. This may also increase the drying shrinkage of the hardened concrete. Where water is not added, the reduced setting time and workability increase the potential for inadequate compaction (itself of a major influence on strength), the formation of cold joints and poor finishes.

Concrete temperature- Hot weather conditions may accentuate the temperature rise in concrete caused by the heat of hydration. In large sections thermal gradients through the element may cause thermal cracking. Laboratory tests show that sustained higher temperatures significantly influence the compressive strength gain of hardened concrete. While increased concrete temperatures may result in an increase in the early rate of strength gain, in the longer term, concrete cured at lower temperatures will achieve higher ultimate strength.

Poor surface appearance- With the increased rate of evaporation, the surface of the concrete will dry out and stiffen. In the case of flatwork this may lead to premature finishing of the surface, trapping an amount of bleed water within the mix. The compacted surface layer (from finishing) may cause the rising bleed water to be trapped below the surface, resulting in debonding of the surface layer and subsequent flaking. Also, colour differences on the surface may result from different rates of hydration and cooling effects.

Plastic shrinkage cracking- Hot weather conditions accelerate the loss of moisture from the surface. If the rate of evaporation is greater than the rate of bleeding (rate at which water rises to the surface), surface drying will occur, resulting in shrinkage of the concrete. When the shrinkage stresses exceed the tensile capacity of the concrete, cracking will occur. The likelihood of plastic shrinkage cracking is therefore greater whenever hot weather conditions increase evaporation or the concrete has a reduced bleeding rate. Plastic shrinkage cracks can be quite deep, as the plastic concrete has little capacity to resist shrinkage stresses, and cracks continue to widen and propagate until the shrinkage stresses are relieved. (Note plastic shrinkage cracks seldom extend to free edges, as unrestrained contraction of the concrete is possible at these locations.)

Thermal cracking- Concrete is at risk of thermal cracking when it is first placed, and the heat of hydration raises the temperature of the interior of the concrete. Rapid changes in the temperature of the external concrete surface, such as when concrete slabs, walls or pavements are placed on a hot day followed by a cool night, lead to thermal gradients between the warm/hot interior and the colder external surface. The warmer interior provides a restraint to the colder external surface, which wants to contract. Depending on the temperature differential, cracking of the concrete may result. Massive or thick concrete elements are more at risk because of the insulating effect that the concrete provides to the interior of the element.

Methods to Minimise the Effects of Hot Weather Conditions

Control concrete temperature- Concrete temperatures at the point of delivery are within the range 5°C to 35°C. For high ambient temperatures, precautions need to be taken by the supplier to ensure that the concrete temperature at the point of delivery is within the allowable range. There are a number of options to control the temperature of concrete, including adjusting the temperature of the ingredients and/or cooling of the concrete mix. The mix water offers the most potential for temperature reduction, particularly by adding crushed ice to it, as the latent heat of the ice is considerably higher than that of water.

Admixtures- Various types of chemical admixtures can be beneficial in hot weather conditions. Water reducers (plasticisers) can be used to reduce the water content or to aid the workability. This enables rapid placement and consolidation of the concrete with beneficial effects on the ultimate strength and durability. Set-retarders can provide additional time to place and finish flatwork. With rapid drying of the surface, caution is required with the use of set retarders, as the surface may appear ready for finishing, but the concrete below may still be plastic from the retarder, leading to a 'spongy' feel under foot. This could affect the uniformity of the surface finish.

Cement- Cement type Selection of a particular cement type may provide additional benefits. Using slower hydration cements (eg Type LH) with lower rate of heat development can provide extra time for placing and finishing; reduce the concrete temperature and the risk of thermal cracking upon cooling of the concrete.

Cement content- The temperature increase from hydration of cement in a given concrete is proportional to its cement content. The cement content therefore should be limited to that required to provide strength and durability.

Precautions in Hot Weather Conditions

Problems usually arise when site personnel are not aware of the effect of weather conditions and/or weather conditions change during the placing and/or finishing of the concrete. Improvised responses to unexpected changes is not recommended as the damage that can result from uncontrolled effects of hot weather conditions may never be completely alleviated. The first option to be considered in hot, adverse weather conditions is whether or not to postpone the placement of concrete.

Ensure that site personnel are aware of the effect of weather conditions. Improvised responses to unexpected changes are not recommended. The first option to be considered in hot, adverse weather conditions is whether or not to postpone the placement of concrete. It is often better to wait than risk costly repairs (or even replacement) of defective work.

Concrete Production- The concrete supplier's role is to assist with the placing of concrete in hot weather. Shade stockpiles, sprinkle aggregates ahead of time for evaporative cooling, or cool them by other means. Paint the mixer and storage bins white to minimise absorption of heat from the sun. Use ice as part of the mix water or cool the concrete with liquid nitrogen.

Delivery and Discharge Delays in delivery can undo the best mixing practices. The concrete supplier should set up and maintain a good delay-free schedule for delivering the concrete to the required location on the site. In addition, avoiding prolonged mixing can be an added advantage.

Delivery and Discharge- Delays in delivery can undo the best mixing practices. The concrete supplier should set up and maintain a good delay-free schedule for delivering the concrete to the required location on the site.

- Minimise transport time and avoid unnecessary delays.

- Avoid prolonged mixing. Transit mixer trucks should be discharged as soon as possible after the water has been added to the mix.

- For large projects, consider batching and mixing the materials using a job-site plant.

- Water should not be added to pre-mixed concrete at the job site unless it is part of the amount required initially for the specified maximum water-cement ratio and the specified slump.

Precautions for Pouring Concrete

- Keeping equipment such as mixers, chutes, wheelbarrows, etc. in the shade or covered with wet burlap will reduce the effect of the sun's heat. Forms, reinforcing steel, and subgrade should be sprinkled with cool water just before the concrete is placed. Wetting down the area cools the surrounding air and increases the relative humidity. This not only reduces the temperature but also minimizes the evaporation of water from the concrete. However, be sure there are no puddles or standing water on the subgrade prior to placing the concrete. Sometimes, if it can be scheduled that way, delaying the placing of concrete until evening or late afternoon may result in improved conditions.

- Cooling the water and aggregates is probably the most practical method of controlling concrete temperatures in hot weather. Water is probably the easiest ingredient to cool and the most effective, pound for pound. Cool water should be used when cement mixing, and if water must be stored, it should be stored where it is not in the direct rays of the sun. Tanks should be placed in the shade, and painted white to maintain water at the lowest possible temperature.·

- Water can also be cooled by adding ice or by refrigeration. Aggregates have a pronounced effect on fresh concrete temperature because they represent 60 to 80% of the total weight of concrete. Stockpiles should be shaded from the sun and kept moist by sprinkling. Since evaporation is a cooling process, sprinkling provides effective cooling, especially when the relative humidity is low. Cement temperature has only a minor effect on the temperature of freshly mixed concrete because it represents a relatively small percentage of the total mixture. Curing is a hydration process and requires water to be present.

- Forms should be sprayed with water to keep them damp, or they will absorb part of the mixing water. As soon as the concrete has set sufficiently to prevent marring the surface, it should be covered with straw, burlap, or other materials such as sand and kept moist for several days. Covering with polyethylene plastic sheets or using curing compounds helps in preventing evaporation by air or wind. Anything to prevent rapid dehydration will be helpful.

Placing and Finishing

- For successful placing and finishing it is necessary to provide an environment in which workers and equipment can function well, and concrete can be adequately protected from rapid warming and/or drying.

- Evaporation Control Protect the surface of concrete slabs at all stages against excessive evaporation and premature drying out by using an evaporative retarder such as aliphatic alcohol. Aliphatic alcohols are applied to the freshly placed and screeded concrete surface, where they form a chemical film which reduces the rate at which water evaporates from the surface of the concrete. By controlling the premature drying out of the surface layer of concrete, the tendency for the concrete to shrink and for plastic shrinkage cracking to occur is reduced or eliminated. Most aliphatic alcohols contain a 'fugitive dye' to assist the monitoring of coverage. The dye has no effect on the strength or colour of the concrete.

Curing and Protection

- It is essential that all surfaces be kept continuously moist by curing the concrete, since drying, even intermittently, can produce drying shrinkage and/or crazing type cracking on the concrete surface. Curing should commence immediately after the slab has been finished, and is particularly important during the first day after placement, and in hot or windy conditions.

- Curing methods include ponding with water, use of wet hessian or cotton mats, continuous spray mist, covering with plastic sheeting or sprayed on curing compounds. When forms are removed, curing should be provided to the newly exposed surfaces.

The measures which can be taken at all stages to reduce to adverse effects of hot weather are summarized in Table 2 below.

| TABLE 2 : Summary of measures to reduce the adverse effects of hot weather |

| STAGE |

MEASURE |

| Production |

Shade aggregate stockpiles |

| Spray stockpiles with water |

| Increase cement silo capacity |

| Paint batching plant white |

| Shade water tank |

| Paint water tank white |

| Insulate water pipelines |

| Use chilled water |

| Use ice as part of mixing water |

| Use admixtures to counteract slump loss |

| Use cement or combinations with low heat evolution |

| Minimize mixing times |

| Transit |

Paint mixer trucks white |

| Minimize transit times |

| Batch dry and add water at site |

| Placing and Curing |

Plan operations carefully |

| Match production to placing rates |

| Reduce layer thickness |

| Provide adequate standby vibrators |

| Place concrete at night |

| Minimize placing time |

| Shade workplace |

| Use windbreaks |

| Apply curing early |

Source: Advanced Concrete Technology by John Newman

Control Measures

A number of different methods are used to alleviate the effects of hot weather. They are mostly aimed at reducing the temperature of the concrete at the time of placing by either cooling the ingredients, reducing the heat gain experienced during mixing, transit and placing or by cooling the concrete itself.

Ingredients

The amount of heat contained in a body or mass of material is the product of its mass, specific heat and temperature. The various ingredients in a concrete mix are present in different masses and they have widely different specific heats. The temperature of freshly mixed concrete can be approximated to:

T = 0.22 ( TaWa+TcWc)+TwWw+TaWwa / 0.22(WaWc)+Ww+Wwa

Where,

T = temperature of freshly mixed concrete

Ta, Tc, Tw = temperature of aggregate, cement and mixing water respectively

Wa, Wc, Ww, Wwa = weight of aggregate, cement, mixing water and free water on aggregate respectively in kg/cum

Hence, the reduction in temperature which can be achieved is different for each individual ingredient. As can be seen from the above equation, water has the greatest effect on concrete temperature, kilogram for kilogram, because of its higher specific heat. For a typical mix containing 180 l/m3 of water, a reduction of 7°C in the temperature of the resulting mix can be obtained by using water at 7°C rather than 32°C.

To obtain water at this temperature in climates such as the Middle East would require the use of a chillers plant or the placing of ice in the storage tank. Moderate reductions in temperature can be obtained by shading and painting the storage tanks white and insulating the delivery pipe work.

| Table 3: Problems resulting from cold weather at various stages in the life of concrete |

| STAGE |

EFFECT |

| Production |

Incorporation of frost-bound material |

| Transit |

Cooling of mix |

| Placing, finishing and Curing |

Formation of ice crystals in concrete |

| Increased thermal gradients/increased tendency to thermal cracking |

| Delayed formwork removal |

| Slower gain in strength |

| Greater chance of formwork stripping damage |

| Bleed water may remain on surface |

| Long-term |

Slower setting |

| Slower gain in strength |

| Freeze-thaw damage |

| Variable appearance |

Source: Advanced Concrete Technology by John Newman

Inclusion of ice as part of the mixing water is highly effective in reducing concrete temperature because of the latent heat taken in as the ice melts. Ice absorbs 335 J/g as it changes to water. The most effective method is to use flaked ice placed directly in the mixer to replace part or all of the mixing water.

Role of Aggregates

Although aggregates have a lower specific heat than water, they constitute such a large proportion of the concrete mix that their temperature can have a significant effect on initial concrete temperature. However, it is much more difficult to reduce the temperature of aggregates than it is to reduce the temperature of water. The best practical approach is usually to keep the aggregates as cool as possible by shading the stockpiles from the direct rays of the sun. This is often accomplished in the Middle East by the use of a lightweight roof at high level (high enough for delivery Lorries to tip and for face shovels to extract) with shade netting on the sides. The open access side should be on the face least likely to be affected by the direct rays of the sun, i.e. north in the northern hemisphere. Sprinkling or fog spraying of coarse aggregates with water is effective in reducing aggregate temperatures by evaporation and direct cooling. However, this needs to be controlled as it can result in variations in the surface moisture content.

Role of Admixtures

Admixtures can play a large part in reducing some of the adverse effects of concreting at high temperatures. Water-reducing admixtures can be used to offset the reduction in slump described earlier without increasing the water/cement ratio. Their use may somewhat increase the rate of slump loss. However, even if the initial slump is increased to compensate for any increased slump loss resulting from their use, there will still be a beneficial net reduction in water content. This can also be used to compensate for any reduction in long term strength. Some admixtures may promote early bleeding and this has been found helpful in preventing the drying of the top surface of concrete placed in conditions of high temperature and low humidity.

Cold Weather Concreting

As for the hot weather effects described earlier, cold weather can adversely affect concrete at all stages. Some of the problems are listed in Table 3. However, there can be some benefits from low initial temperature. Concrete which is placed at low temperatures, but which is not allowed to freeze and receives good curing, develops higher ultimate strength, greater durability and is less subject to thermal cracking than similar concrete placed at higher temperatures?

The main problems associated with cold weather are frost damage to immature concrete and slow gain in strength leading to later stripping times and the possibility of increased damage when the shutters are removed. Concrete is vulnerable to freezing temperatures both before and after it has stiffened. There are two stages:

- Expansion of water as it freezes in plastic concrete causes such severe damage that the concrete is unusable.

- Concrete can be permanently damaged by the pressures exerted by ice crystal growth if this occurs after the concrete has stiffened but before it has gained adequate maturity. This weakens the paste-aggregate bond and may reduce strength by up to 50 per cent. The porosity of the concrete may be adversely affected causing a loss of durability.

Warm bodies tend to lose heat to their cooler surroundings. The heat can be transferred by any of three mechanisms - conduction, radiation and convection. Conduction can be considered as the flow of heat along a body or between one body and another. The heat flows from the hotter region to the cooler until the temperature is uniform. Radiation is the transfer of heat in wave form. A good example of this is the heat from the sun which can travel through space and be felt on Earth. Convection occurs in fluids and involves relative movements of regions of fluid at different temperatures. If a warm region exists in a fluid, the fluid in this region will be less dense than the remainder because of the expansion associated with rise in temperature. Hence the warmer fluid starts to rise.

Cooler fluid moves in to replace the rising warmer fluid and convection currents are set up. The process is continuous under conditions where no heat is added until the temperature is more or less uniform throughout the fluid. Concrete can lose the heat produced during hydration by all three of these processes: by conduction to the formwork and adjacent concrete; by radiation to an open sky on a clear night; and by convection to the air above. The heat loss from concrete increases in high winds and in addition, the wind increases the rate of evaporation thus removing more heat from the concrete.

Ingredients

The most simple and effective means of producing concrete with a temperature above 5°C in cold weather is to use heated water. This will usually be all that is required except in the most severe circumstances with ambient temperatures below freezing point for prolonged periods. In this case it may also be necessary to heat the aggregates.

|

A number of different techniques are available for heating the mixing water. Steam can be used either by injection or by passing it through a coil in the storage tank. If a steam plant is used for heating the water, steam lances can be used for thawing out the surface of aggregate stockpiles. Immersion heaters are also available for electrical or propane operation. The storage tank must be insulated to cut down heat loss and of sufficient capacity that a supply of heated water is available at uniform temperature at time of peak demand. The mixer's own water tank should also be lagged and all pipe work should be lagged or buried at a level below that influenced by frost (450-600 mm deep). An alternative to lagging of pipes is electrically operated low-voltage insulated heating tape.

|

Aggregate stockpiles should be free of lumps of snow, ice or aggregate. Lumps which are larger than 75 mm can survive the mixing process and remain in the concrete until it is placed. Windbreaks should be erected around the stockpiles and batching plant to reduce the chill factor. The stockpiles should be protected from the action of frost by covering them with tarpaulins or, better still, by an insulating layer covered with tarpaulins or other waterproof sheet. Overhead metal storage bins should have their sides insulated and the covers should be kept in place continually except when material is being loaded.

Aggregate stockpiles can be thawed out or heated by use of steam in a number of different ways:

- As noted above, steam lances can be used for dealing with a superficial layer of frost affected aggregate

- Closed Steam coils under the stockpiles

- Injecting steam into the stockpiles

If the steam is in a closed-pipe system there is the possibility of hot dry spots within the stockpiles. Steam jets liberated within the stockpile can cause moisture variation. Another means of heating aggregates is the use of flexible insulating mats which contain electrical heating elements. When a spell of cold weather is forecast, the aggregate stockpiles should be built up in anticipation that there may be a restriction on deliveries either because of poor conditions on the roads or because the pits are frozen.

Few additional precautions are needed for cement storage except that, if it is to be stored in silos for an extended period, these should be lagged to reduce heat losses and also to prevent condensation. Consideration should be given to using faster-reacting cements or avoidance of cement types which prolong gain in strength so that the possibility of damage before the concrete has gained sufficient strength is reduced and shutter stripping times are not excessive.

|

|

|

|

Accelerating admixtures can also be used to increase the rate of strength gain. Air entraining admixtures are used to combat the detrimental effects of freeze/thaw cycles on hardened concrete. ACI 306 recommends that any concrete likely to be exposed to freezing in a saturated condition during construction should be properly air-entrained even though it will not be exposed to freezing in service.

Hydration Process

The hydration of cement is a chemical reaction that produces heat. In cold weather, the cement hydration is slower and concrete gains strength less quickly, increasing the time to attain its design strength. The vulnerability of newly placed concrete during cold weather needs careful consideration to avoid damage from frost or overloading of immature concrete.

Definitions

Low temperatures have a number of effects on the behaviour of the concrete; most of these are related to the reduction in the rate of cement hydration. Cold weather is defined as a period when the average daily temperature falls below 40°F [4°C] for more than three successive days. These conditions warrant special precautions when placing, finishing, curing and protecting concrete against the effects of cold weather. Since weather conditions can change rapidly in the winter months, good concrete practices and proper planning are critical.

Indian Standard defines cold weather concreting as 'any operation of concreting done at about 50C atmospheric temperatures or below. In the context of concreting, ACI defines cold weather as a period when, for more than three consecutive days when the average daily air temperature is less than 50C and the air temperature is not greater than 100C for more than one-half of any 24 hour period. The average daily air temperature is the average of the highest and the lowest temperatures occurring during the period from midnight to midnight.

Effects of Low Temperatures

Low temperatures have a number of effects on the behaviour of the concrete; most of these are related to the reduction in the rate of cement hydration. When the temperature is falling to about 5°C or below, the development of concrete strength is retarded compared with the strength development at normal temperature. The hardening period necessary before the removal of forma is thus increased and the experience from concreting at normal temperature cannot be used directly.

Extended Setting Times- The lower rate of cement hydration at low temperatures increases the setting times. Combined with the increased time for bleed water to evaporate in low temperatures, concrete finishing operations will be delayed, and this may add cost. If the concrete is finished prematurely, problems may be experienced with delamination (or flaking) and weak, dusty surfaces. The practices of adding cement or cement/sand mixtures to the surface of the slab to use up excess water and allow finishing to proceed should be avoided as it will inevitably lead to poor wear resistance.

Freezing of Concrete at Early Stages- When concrete i. exposed to freezing temperature, there is the risk of concrete suffering irreparable loss or strength and other qualities, that is, permeability may increase and the durability may be impaired.

Repeated Freezing and Thawing of Concrete- If concrete is exposed to repeated freezing and thawing aftre final set and during the hardening period, the final qualities of the concrete may also be impaired.

Slower Strength Gain- At low temperatures the gain in concrete strength is considerably slower than at normal temperatures; this will delay the removal of formwork.

Cracking- The extent of cracking may also be increased, as the lower concrete strength may be inadequate to resist the drying shrinkage stresses and /or thermal stresses. The latter may result from the temperature difference between the inside and the (cold) surfaces of the element, particularly in thick sections.

Freezing- Freshly placed concrete is vulnerable to freezing conditions both before and after it has set. As a general rule, concrete must be protected from freezing for at least 24 hours after placement. If there is a possibility that freezing can occur prior to setting, precautions should be taken to protect the concrete elements or the concrete should not be placed. If allowed to freeze after setting (ie sudden drop in temperature overnight), the expansion of the water as it freezes will cause damage to the pore structure of the cement paste, thus reducing the potential strength of the concrete. The extent of the damage will depend on its age and strength when frozen.

Precautions for Concreting in Cold Weather

Temperature Control of Concrete Ingredients- The most direct approach to keeping concrete temperature up is by controlling the temperature of its ingredients. The contribution of each ingredient to the temperature of concrete is a function of the temperature, specific heat and quantity used of that ingredient. The aggregates and mixing water exert the most pronounced effect on temperature of concrete. Thus, in cold weather, all available means shall be used for maintaining these materials at as high a temperature as practicable.

Most methods to minimise the effects of low temperatures involve increasing the rate at which concrete gains strength under these conditions in the important early stage after placement.

Cement Quantity- Increasing the quantity of cement (ie using a higher-strength concrete) can significantly increase the rate of strength gain. Note that there is little or no impact on the setting time.

Cement Type- High-early strength cements (Type HE) will gain strength more rapidly than general purpose portland cements (Type GP). Their use also results in heat being generated more rapidly within the concrete, thereby increasing its temperature. There is no significant difference in the setting times between the two types.

Admixtures- The addition of an accelerating admixture (non-chloride) to the concrete reduces the setting time and accelerates the rate of strength gain by increasing the rate at which the cement hydrates.

Hot Water- Using hot water in the mix will raise the temperature of the concrete, which in turn accelerates the rate at which the cement hydrates. The temperature of mixing water should not exceed 70°C and mixing should ensure consistency in the temperature of the concrete delivered to site.

Air Entrainment- It may be possible to provide some protection against the effects of sudden freezing by incorporating an air-entraining admixture into the concrete. These admixtures create minute air pockets/spaces into which pore water can move as it expands during freezing.

On-Site Precautions- It is desirable to take precautions against damage to the concrete by a sudden and unexpected frost or whenever the air temperature drops below 5°C.

Protection from the Cold (including cold/frozen ground, winds and frosts)- In some situations, the provision of a heated enclosure (light frames covered with tarpaulins and the use of hot-air blowers) to completely encase the concrete element may be required. Note that care should be taken to prevent the drying out of the concrete when using this approach.

Insulated Formwork

It is vital to insulate formwork, particularly steel forms, and unformed pour surfaces. Once forms are stripped, concrete should be protected to maintain heat and permit development of the required strength. During the first 24 hours, hydrating cement generates a significant amount of heat which, if retained within the concrete by insulation, will protect it from freezing. Timber formwork is a reasonable thermal insulator and will probably suffice for moderately cold conditions. Additional insulation will be required for more-severe conditions, or for prolonged periods or freezing weather. Metal formwork offers little or no protection and should be insulated.

- Insulating materials should themselves be waterproof, or be protected to keep them dry, as many materials are excellent insulators when dry, but ineffective when wet. Note that expanded polystyrene sheets are relatively unaffected by moisture. Mineral wool quilts provide effective thermal insulation. Supplied in standard widths and lengths, they can be laced together to form the required size. They may be wrapped around corners.

- Foam mats are thermally efficient and relatively flexible. They may be easily cut to shape and size. They should be joined with an overlap of at least 300mm and can be laid in several layers for increased protection.

- Polythene sheet does not provide heat insulation in itself, but can be used on a frame to create an air gap against the concrete surface, providing some protection against a slight frost. Warm-air heating may also be introduced. A useful material is 'bubble wrap', where the air bubbles are placed against the concrete or formwork to create the additional insulation.

- When the insulation is removed, care should be taken to avoid a sudden change in temperature at the concrete surface and development of steep temperature gradients within the concrete element. This is especially important with thicker sections. Whatever precautions are taken, concrete should still be cured in the normal way.

- In extended periods of cold weather, it may be advantageous to completely tent the working area, with temperatures controlled by heaters, thermal blankets, etc. A particular case is where composite steel decking is used. The soffit formwork provides no insulation; the slab is thin and so very vulnerable.·

- Creating an enclosure beneath the suspended slab may allow concreting to continue, the upper slab surface being insulated with matting in the usual manner. It is recommended that the formwork be left in position for as long as practical to protect the concrete from frost.

Adjustments to the mix design

The concrete mix can be adjusted to improve the rate of strength gain. It is possible to use any of the following techniques, either separately or in combination:

- increase the cementitious content

- opt for a plain Portland cement instead of a blended cement

- increase the concrete strength class

- use a more rapid setting cement (42.5R rather than 42.5N)

- increase the cement strength class (e.g. 52.5 instead of 42.5)

- use water-reducing admixtures to improve early strength gain(5)

- incorporate a set-accelerating admixture(5)

Curing

All concrete should be cured to ensure that it achieves its maximum potential strength and durability. During prolonged periods of freezing conditions this can pose particular problems as moist or water curing is rarely appropriate. Common solutions include use of an insulation blanket or covering, particularly where concrete has been placed in insulated forms. When formwork is removed, the member should be further cured by covering it with plastic sheeting, or tarpaulins, properly lapped at joints and secured to ensure wind-tightness. Note that concrete newly released from insulated formwork or heated enclosures should never be saturated with cold water. Rather, care should be taken not to suddenly expose warm concrete surfaces to cold conditions. The temperature of surfaces should always be allowed to fall slowly to avoid thermal cracking due to a temperature differential between the surface and interior of the element, particularly larger/thicker elements.

Conclusion

Successful winter concreting poses a number of problems, and appropriate precautions must be implemented. However, there is no reason why concrete placed under cold or freezing conditions cannot achieve the same strength and durability as concrete placed in normal conditions. It has seen that the temperature variation results in both positive and negative impacts on different properties of concrete. It also yields good results but keeping in view the demand of concrete's strength the temperature of the environment under which it is mixed, cast, cured and finally tested must be controlled. Increase in temperature increases initial strength while at the same time it reduces the long term strength.

References:

http://www.idc-online.com/technical_references/pdfs/civil_engineering/Hot_Weather_Concreting.pdf

http://www.concreteconstruction.net/images/Hot%20Weather%20Affects%20Fresh%20Concrete_tcm45-342403.pdf

http://www.itacanet.org/doc-archive-eng/contruction/hotcon.pdf

http://pubstorage.sdstate.edu/AgBio_Publications/articles/ExEx1006.pdf

http://www.elvingroup.com.au/wp-content/uploads/2014/07/cold_weather.pdf

http://builderssupply.net/cip/27%20-%20Cold%20Weather%20Concreting.pdf

http://www.cipremier.com/e107_files/downloads/Papers/100/31/100031018.pdf

https://law.resource.org/pub/in/bis/S03/is.7861.2.1981.pdf

http://www.roadmix.com/fs/doc/publications/129-cold-weather.pdf

http://www.sakrete.com/media-center/blog-detail.cfm/bp_alias/Placing-Concrete-in-hot-or-cold-weather

Advanced Concrete Technology by John Newman